Sti cleaning process suitable for novel storage structure

A storage structure and process technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as tension collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

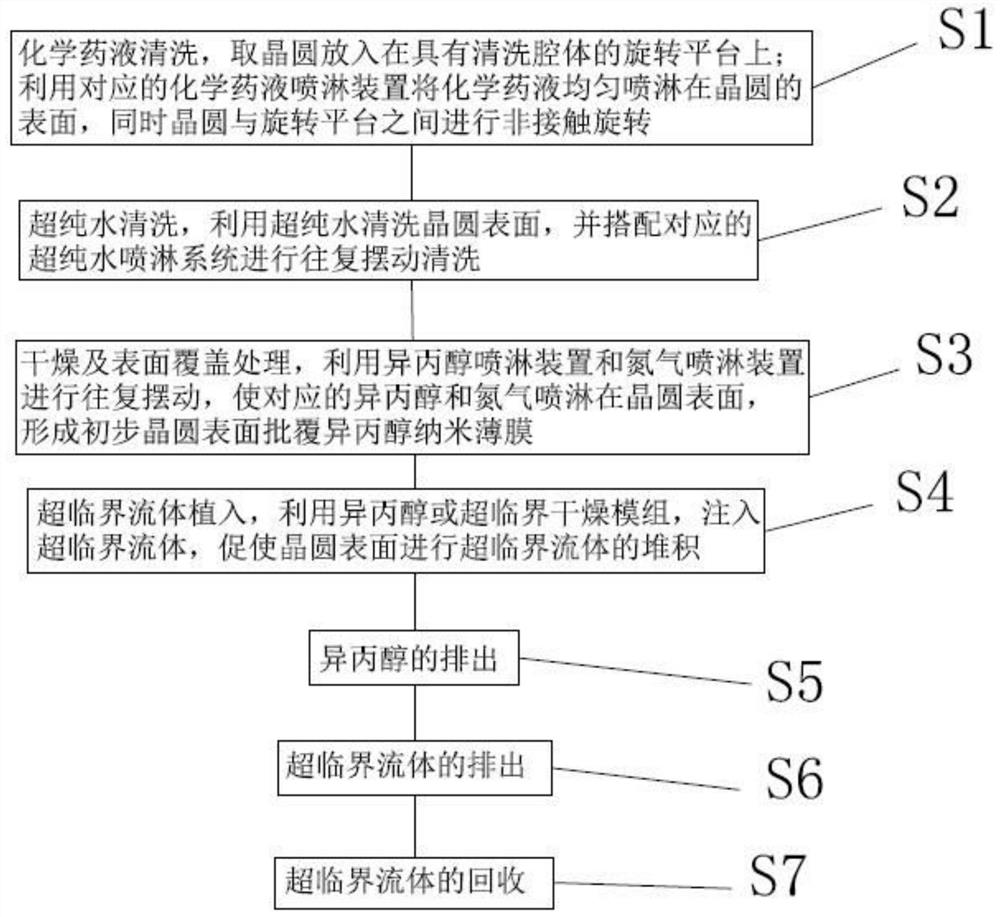

Method used

Image

Examples

Embodiment approach

[0042] Further, as a preferred embodiment, it also includes secondary cleaning of chemical liquid. After the wafer is cleaned with ultrapure water, the surface of the wafer can be cleaned with chemical liquid for the second time, in order to eliminate Static electricity on the wafer surface, using ultrasonic nano-spray system or corresponding cleaning process used by other chemical liquid. The rotating platform in the center of the body performs non-contact rotation. Among them, the chemical liquid in the second chemical liquid cleaning process is diluted APM (ammonia water, hydrogen peroxide) and carbon dioxide is added to make it easier for APM to contact the surface of the wafer. The electrostatic double layer effect on the surface is generated, forming a denser surface energy barrier, forming a complete charge blocking layer, and eliminating the phenomenon of particle diffusion and adhesion on the wafer surface.

[0043] Further, as a preferred embodiment, after the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com