Automatic salad processing system

A processing system and salad technology, applied in applications, food processing, grain processing, etc., can solve the problems of strong irritating smell, poor blanching effect, poor heating effect, etc., and achieve the effect of reducing stimulation and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

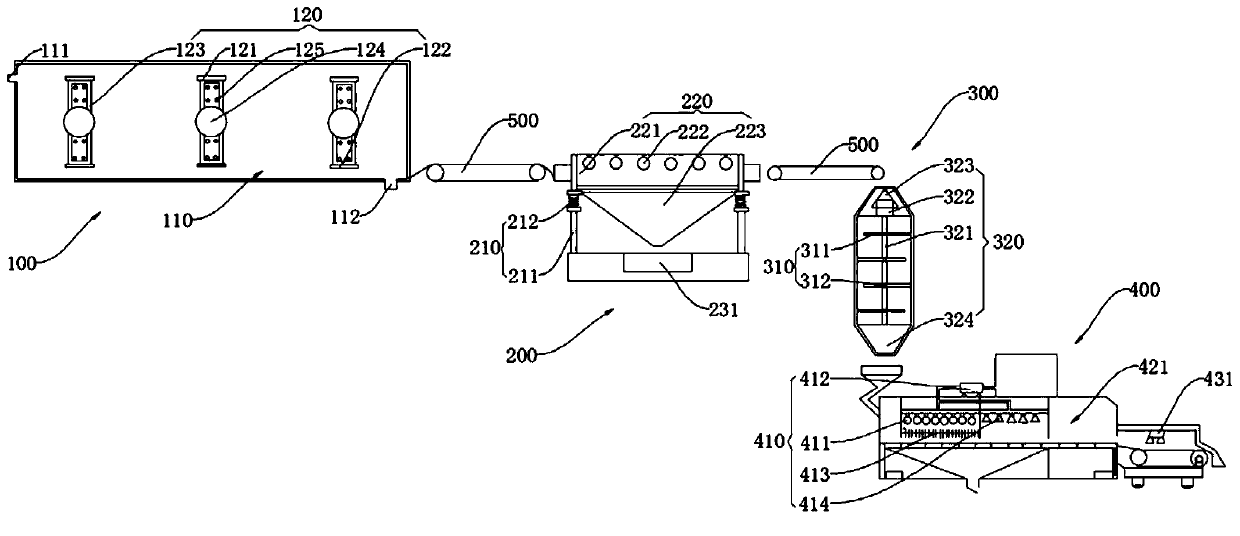

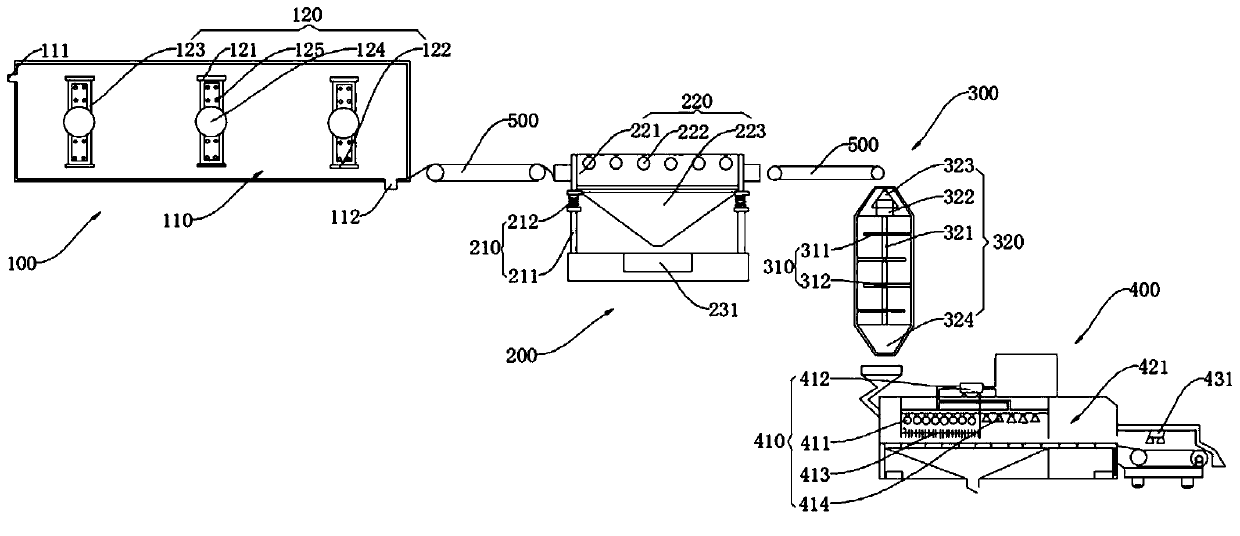

[0026] refer to figure 1 , an automatic blanching processing system for vegetables, comprising a blanching unit 100 and a cooling unit 300, and the blanching unit 100 and the cooling unit 300 are connected through a hoist 200. In this embodiment, the blanching unit 100 is used for blanching the products, the elevator 200 is used for transporting the blanched products to the cooling 300, and the cooling 300 is used for cooling the blanched products deal with.

[0027] In this embodiment, the blanching unit 100 includes a feeding port 190 for feeding materials. It also includes a preheating unit 130, a blanching unit 140 and a blanching heating device 160, wherein the preheating unit 130 is used for preheating the product, and the blanching unit 140 is used for blanching the preheated product Treatment, the blanching heating device 160 is used to provide steam with a certain temperature required for preheating treatment and blanching treatment.

[0028] In this embodiment, th...

Embodiment 2

[0044] With respect to Embodiment 1, the difference is that in Embodiment 2, an insulation layer is provided inside the casing of the blanching part 100 for heat insulation treatment of the blanching operation, so as to ensure that the temperature will not be affected by the outside and ensure the smoothness of the blanching operation. efficiency and effectiveness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com