Improved hollow fiber nanofiltration membrane assembly

A nanofiltration membrane and hollow technology, which is applied in the field of improved hollow fiber nanofiltration membrane modules, can solve problems such as short-circuit filtration, strong impact and disturbance of membrane elements, and influence on the stability of membrane system operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

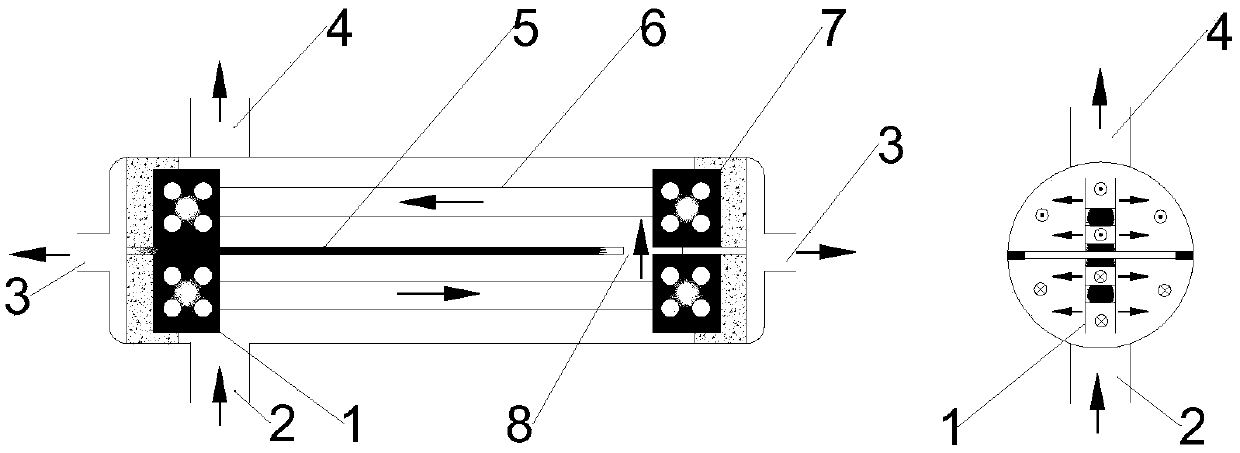

[0024] Such as figure 1 As shown, a hollow fiber nanofiltration membrane module includes a membrane casing and a flow-guiding filter element arranged in the membrane casing; the flow-guiding filter element includes a membrane filament arranged in a liquid channel for filtering unit 6, deflector 5 for improving fluid distribution, compartment 1, and a resin-cast fixing layer 7 arranged at both ends of the membrane shell for fixing the membrane filament unit 6 and the deflector 5, The compartment 1 is arranged next to the fixed layer 7, the left side of the compartment and the membrane filament unit are cast at one end of the membrane shell with resin, and the right side of the compartment is set at the liquid inlet 2 and the liquid output 3 of the membrane shell. In the projection area of the deflector 5, the upper and lower ends of the membrane shell are respectively provided with a liquid inlet 2 and a concentrated liquid discharge port 4, and the left and right ends are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com