Surface processing device for automobile shell

A surface processing and automobile shell technology, applied in the field of automobile shell surface processing devices, can solve the problems of exhaust gas treatment, external air pollution, etc., and achieve the effect of improving painting efficiency, avoiding pollution of external air, and flexible and adjustable height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

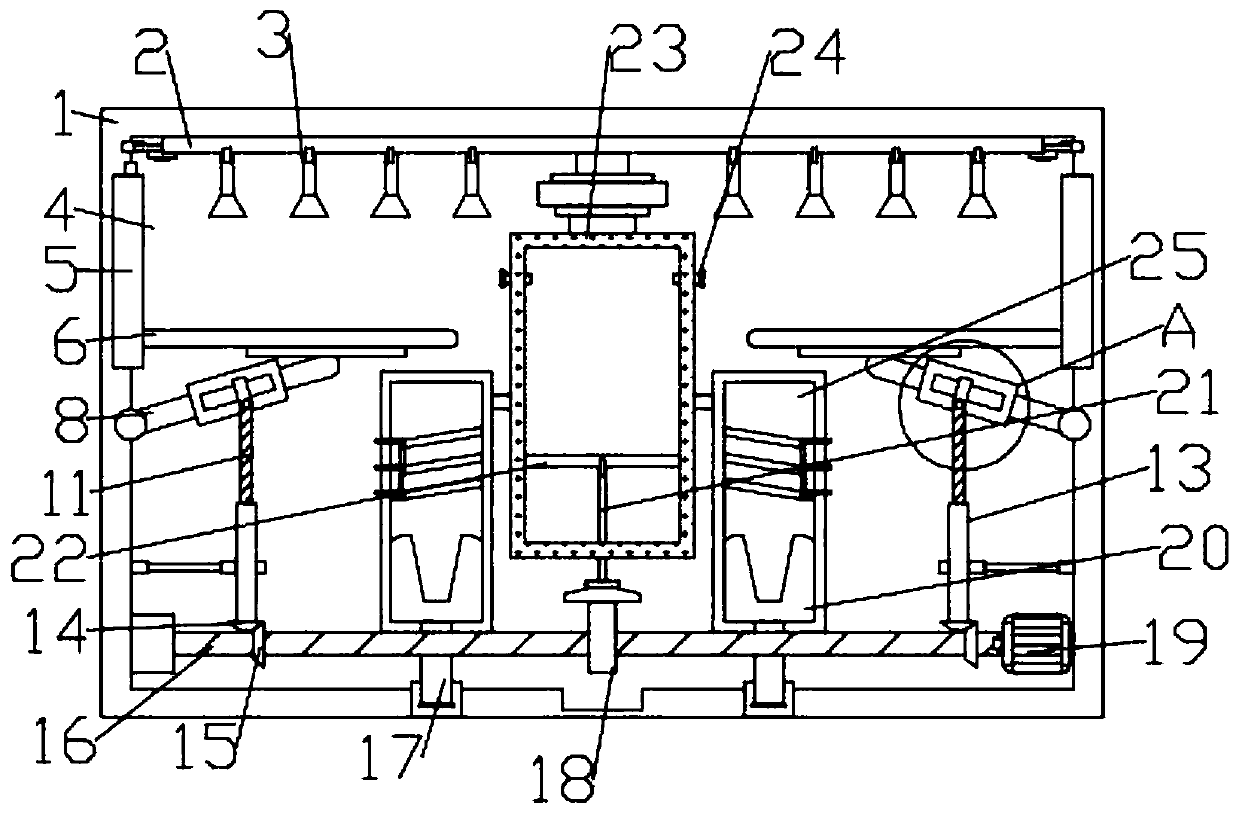

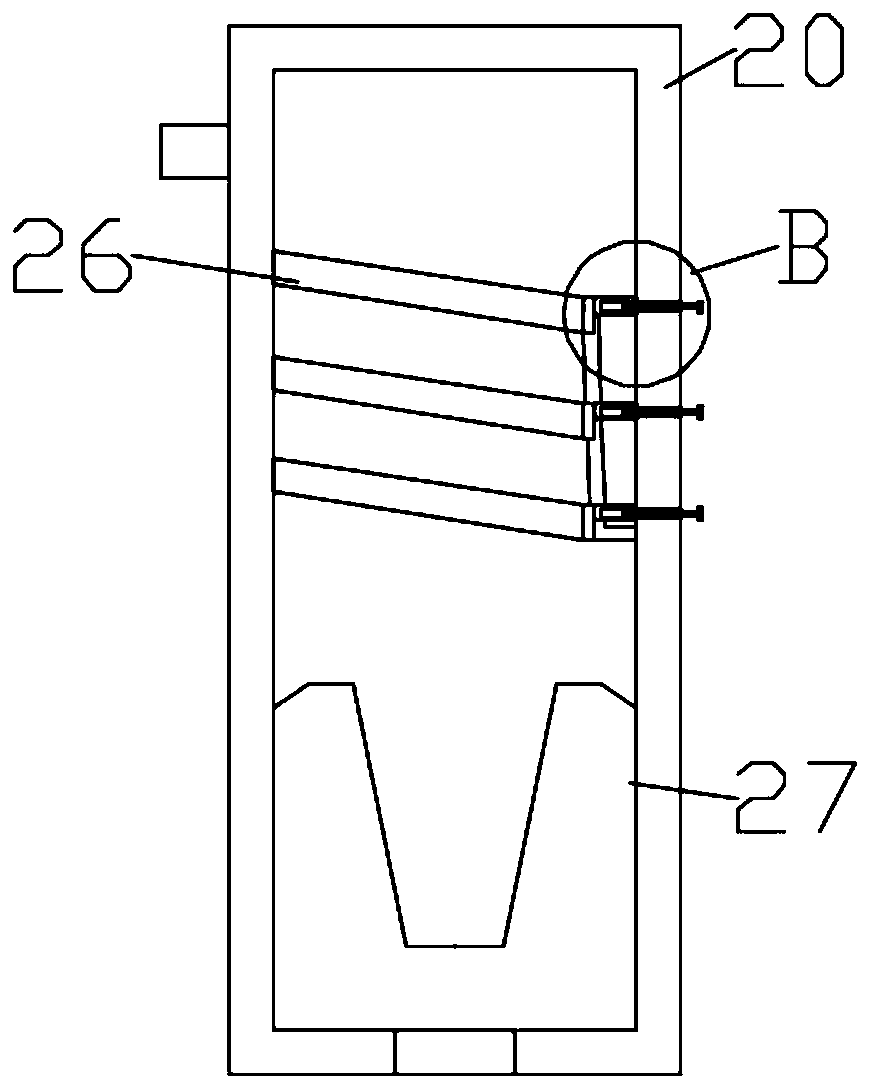

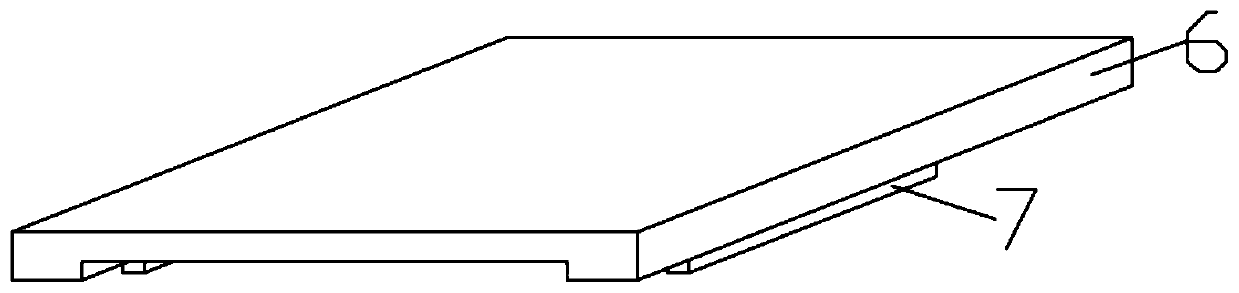

[0022] Such as figure 1 As shown, in the embodiment of the present invention, a kind of automobile shell surface processing device comprises casing 1 and processing chamber 4, and processing chamber 4 is provided with in casing 1, and the top of processing chamber 4 is provided with painting assembly, and the top of processing chamber 4 The middle part is symmetrically provided with a load-bearing assembly for placing the shell, and the lower part of the load-bearing assembly is provided with a driving assembly for adjusting the height of the load-bearing assembly. There is an air extraction assembly between the load-bearing assemblies, and filter assemblies are connected to both sides of the air extraction assembly through an air duct;

[0023] The paint spray assembly includes a paint spray pipe 2 and a spray nozzle 3, one end of the paint spray pipe 2 is fixedly connected to the side wall of the box body 1, the other end of the paint spray pipe 2 is connected to a paint stor...

Embodiment 2

[0033] Such as figure 1 As shown, in the embodiment of the present invention, a kind of automobile shell surface processing device comprises casing 1 and processing chamber 4, and processing chamber 4 is provided with in casing 1, and the top of processing chamber 4 is provided with painting assembly, and the top of processing chamber 4 The middle part is symmetrically provided with a load-bearing assembly for placing the shell, and the lower part of the load-bearing assembly is provided with a driving assembly for adjusting the height of the load-bearing assembly. There is an air extraction assembly between the load-bearing assemblies, and filter assemblies are connected to both sides of the air extraction assembly through an air duct;

[0034] The paint spray assembly includes a paint spray pipe 2 and a spray nozzle 3, one end of the paint spray pipe 2 is fixedly connected to the side wall of the box body 1, the other end of the paint spray pipe 2 is connected to a paint stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com