Coating method based on coating machine

A coating method and coating machine technology, which can be applied to devices and coatings for coating liquid on the surface, can solve problems such as sagging and affect product quality, and achieve the effect of ensuring the effect of gluing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

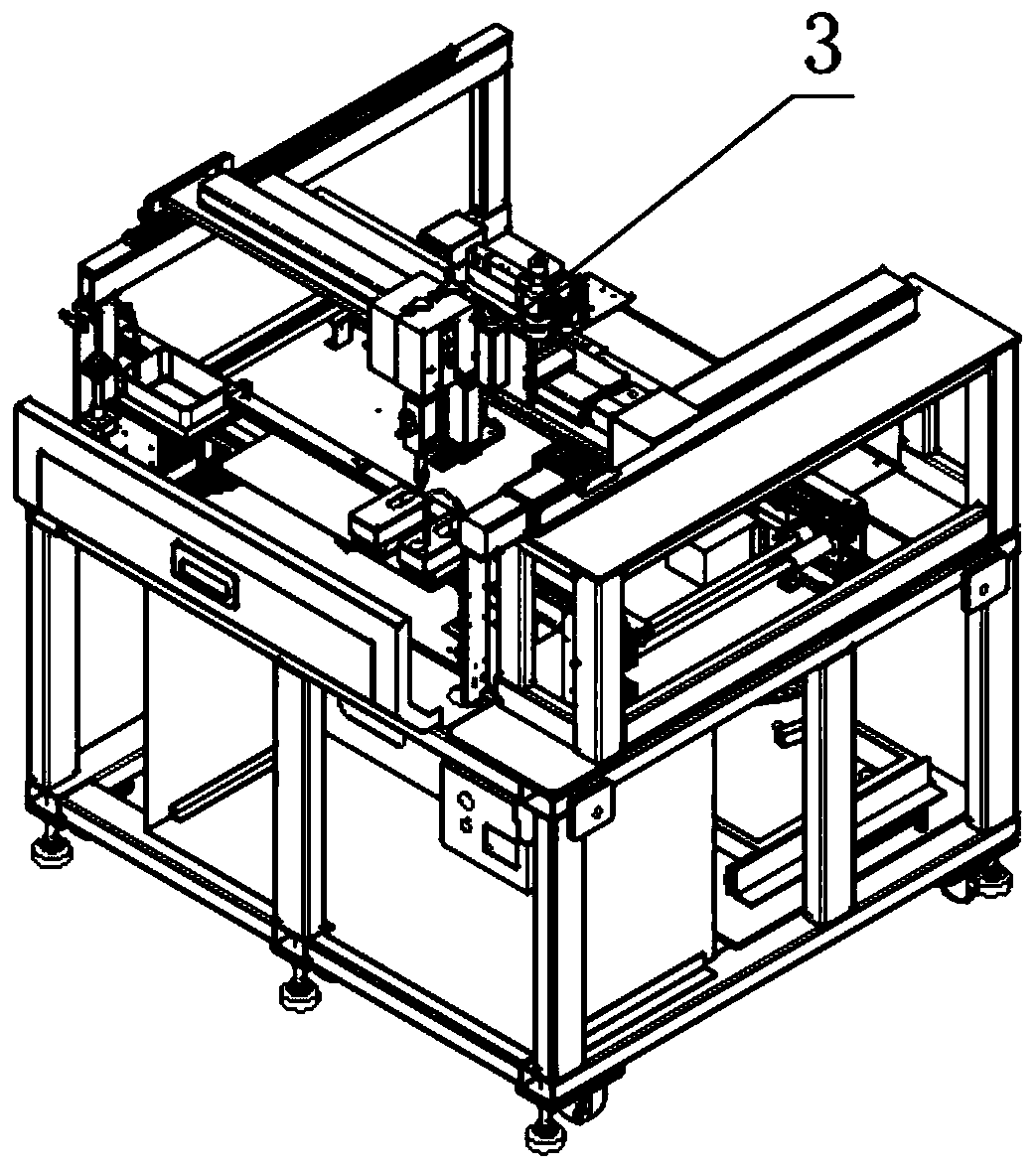

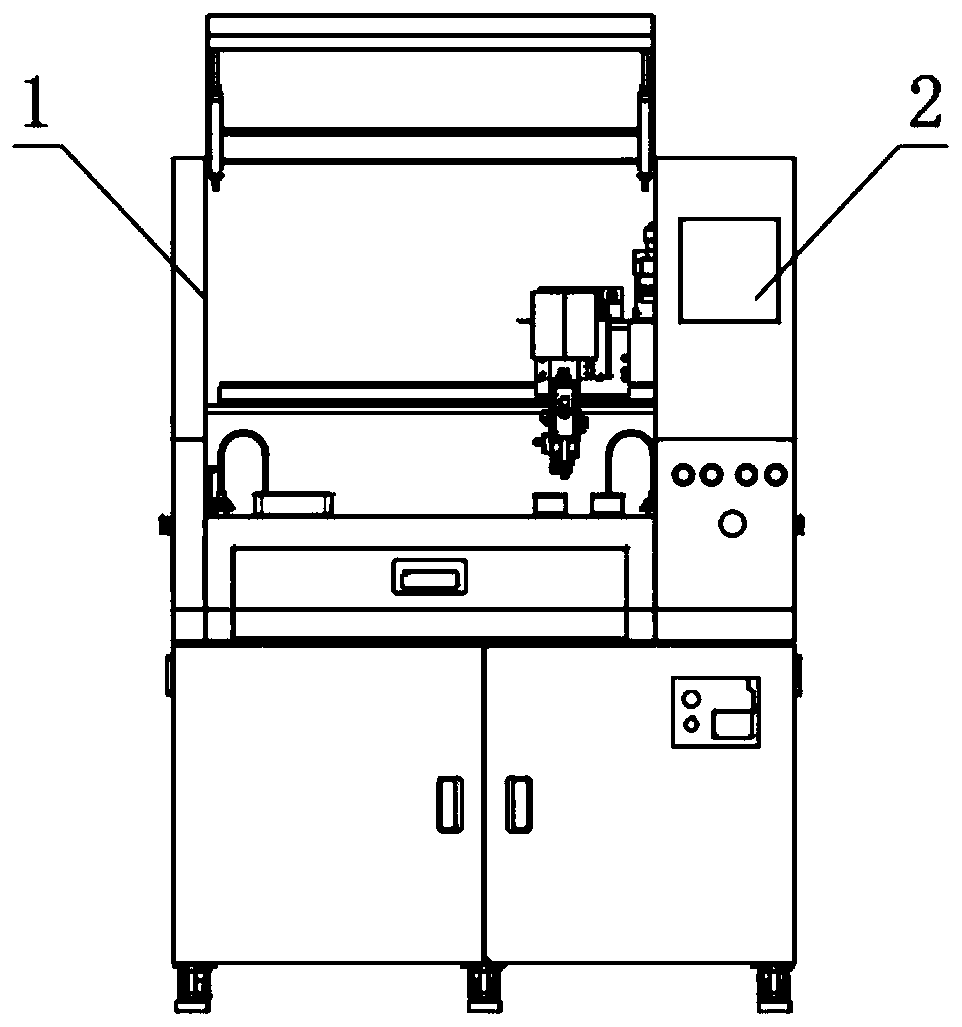

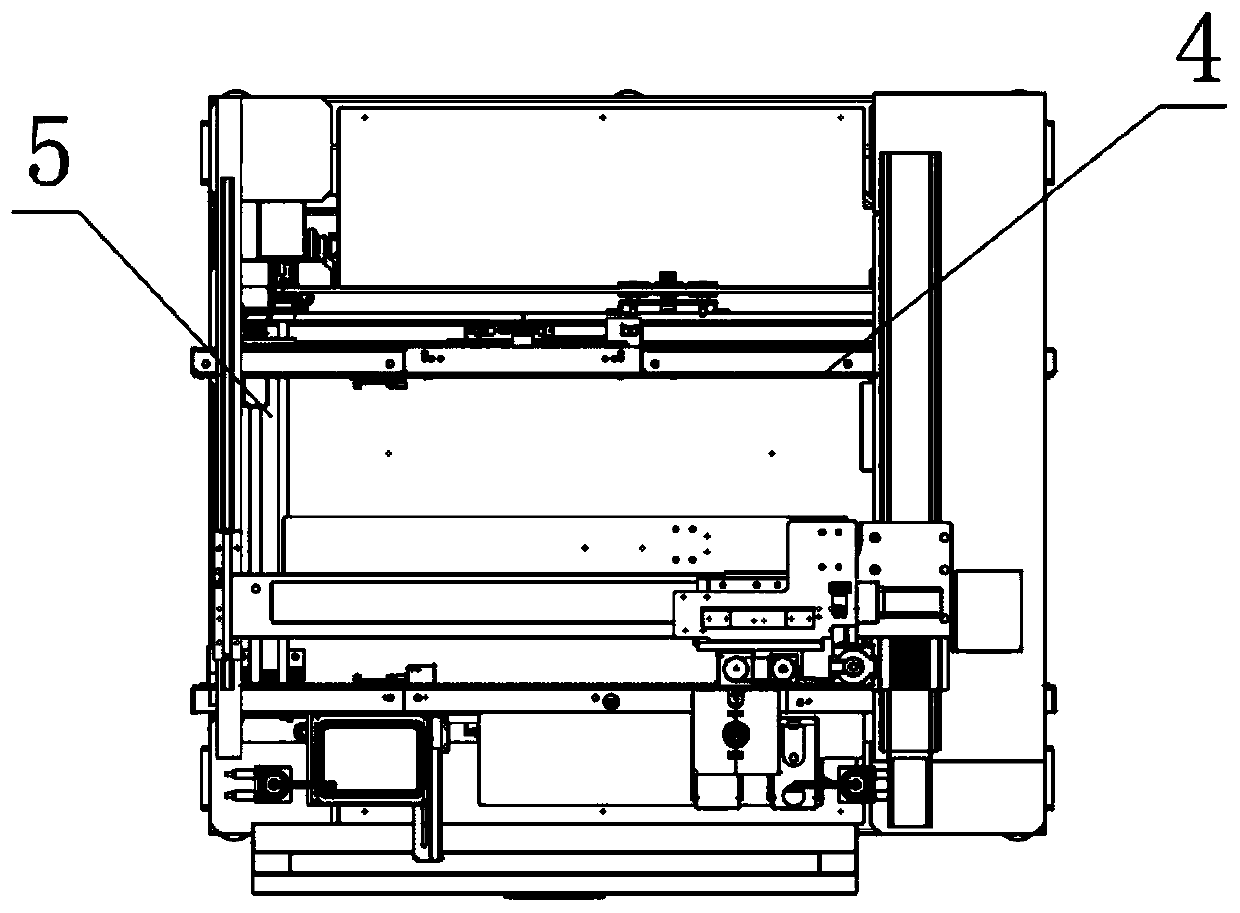

[0089] Such as Figure 1-Figure 4 , Figure 13-Figure 14 Shown, a kind of coating machine comprises:

[0090]Frame 1 is mainly welded with square steel, and the sealing plate is formed by overtime metal parts. The frame is integrated and has good stability; the control panel 2 is set on the frame 1 and can be controlled through the touch screen control panel. The acceleration and deceleration of the whole machine, and the switching of different product parameters; the glue supply system 3, the glue supply system 3 is set inside the frame 1; the XY horizontal movement system 4, the XY horizontal movement system 4 is fixed on Above the frame 1, the XY horizontal moving system 4 includes: an X mobile manipulator 26, the X mobile manipulator 26 is arranged horizontally, and the right end of the X mobile manipulator 26 is provided with a servo motor 2 23; the Y mobile manipulator 27, the The Y mobile manipulator 27 is longitudinally provided with the Y mobile manipulator 27. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com