Gravel filtering device for coastal engineering construction

A technology for engineering construction and filtration devices, which is applied in the direction of filtration and separation, fixed filter element filters, filter screens, etc., can solve problems affecting the quality of sand and gravel, poor construction environment, and insufficient filtration, so as to ensure environmental quality and improve filtration. Efficiency, dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

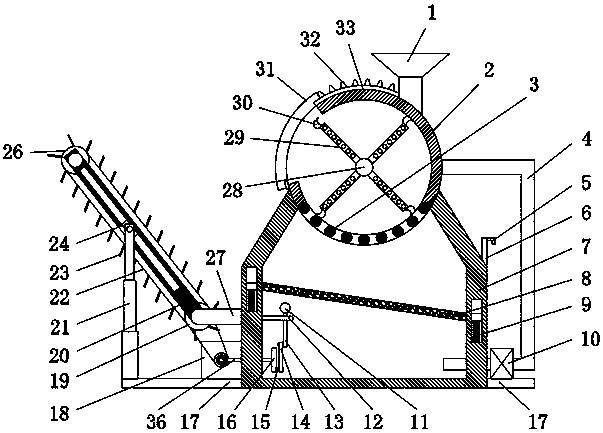

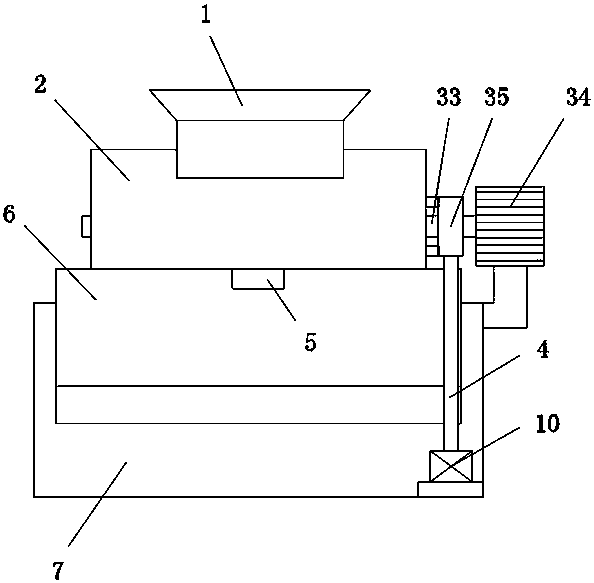

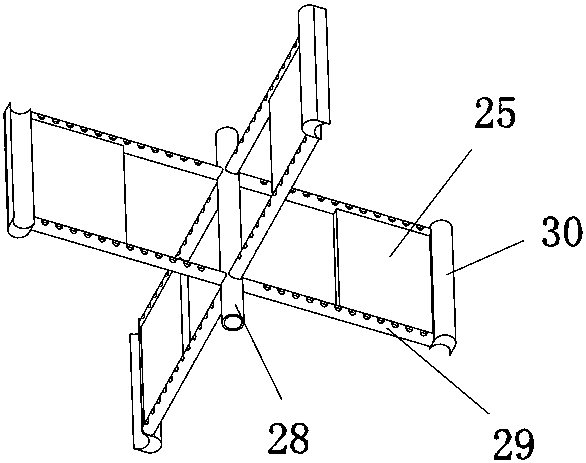

[0021] see Figure 1~3 , in an embodiment of the present invention, a sand filter device for coastal engineering construction includes an impurity storage box 7 and a water washing filter mechanism fixedly installed on the impurity storage box 7, and the water washing filter mechanism includes a filter cartridge 2 and is fixedly installed on the The second drive motor 34 on the impurity storage box 7, the top of the filter cartridge 2 is fixedly installed with the feed port 1, the filter cartridge 2 is rotated and provided with a rotary tube 28, and the rotary tube 28 is connected with a stirring tube 29 and the stirring tube 29 A water spray hole is arranged on the top, a discharge plate 25 and a scraper 30 are fixedly installed on the stirring tube 29, the rotating tube 28 is fixedly connected with the output end of the second driving motor 34, and a sealing box 35 is fixedly installed on the filter cartridge 2 And the sealing box 35 is provided with a cavity, the rotating t...

Embodiment 2

[0029] In order to further quickly discharge the sand on the filter screen 8 from the impurity storage box 7 and prevent impurities from clogging the filter screen 8, this embodiment has been further improved on the basis of embodiment 1, compared with embodiment 1 , the main difference is that: both sides of the impurity storage box 7 are provided with chutes, the filter screen 8 is slidingly stuck in the chute on both sides of the impurity storage box 7 and the filter screen 8 is connected to the impurity storage box by the buffer spring 9 7 are elastically connected, and the bottom of the impurity storage box 7 is provided with a rotating shaft 36, one end of the rotating shaft 36 is connected to the output end of the first drive motor 18 through a bevel gear, and the other end of the rotating shaft 36 is fixedly equipped with a rotating disk 16. A shaft pin 15 is fixedly installed on the turntable 16, a first support 12 is fixedly installed on the side wall of the impurity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com