Working method for building steel tube column welding auxiliary device

A technology for auxiliary devices and working methods, applied in the direction of auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve problems such as inability to clamp pipes, inability to weld electric and full welding, and inability to adjust welding angles, etc., to speed up clamping Efficiency, the effect of avoiding thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

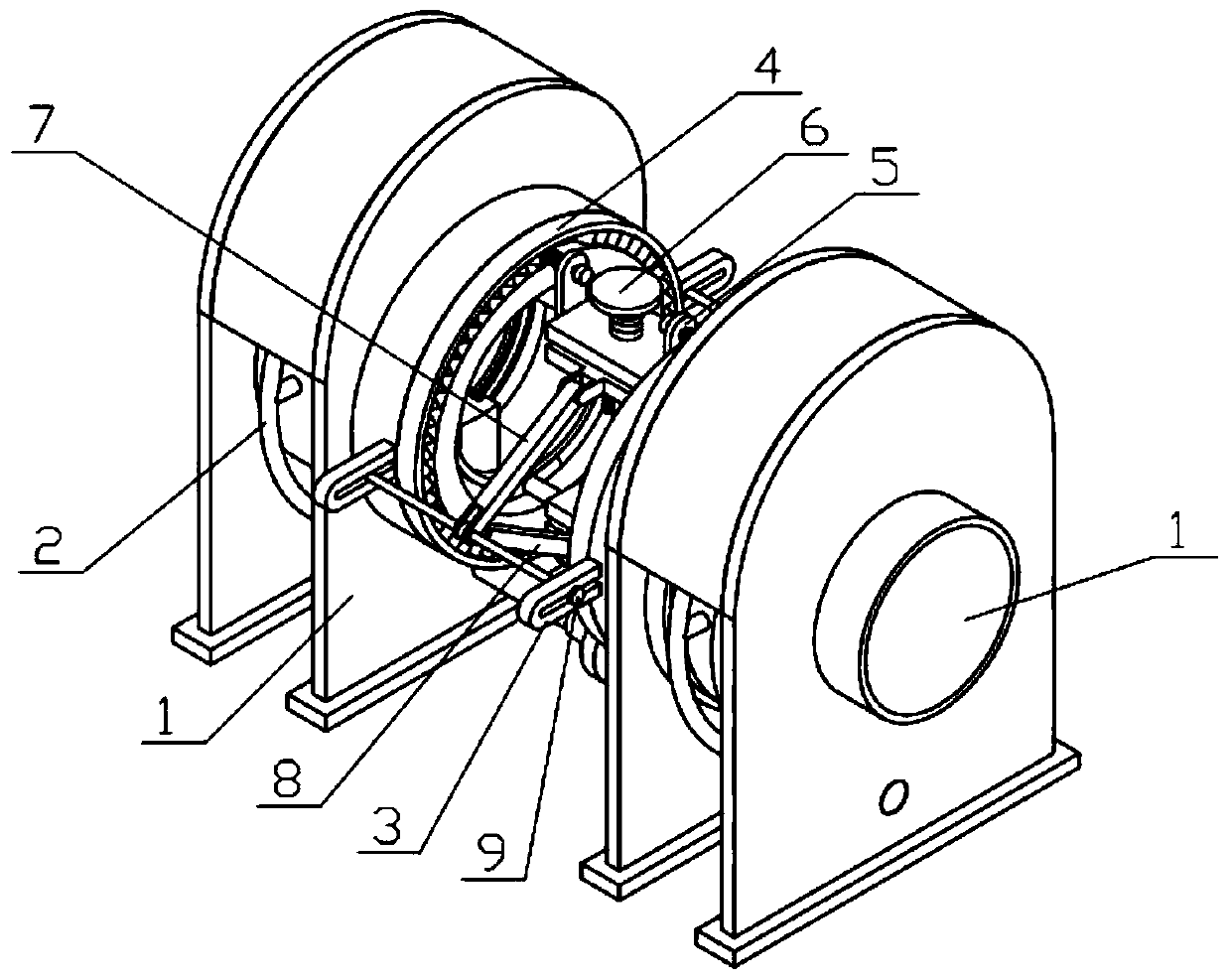

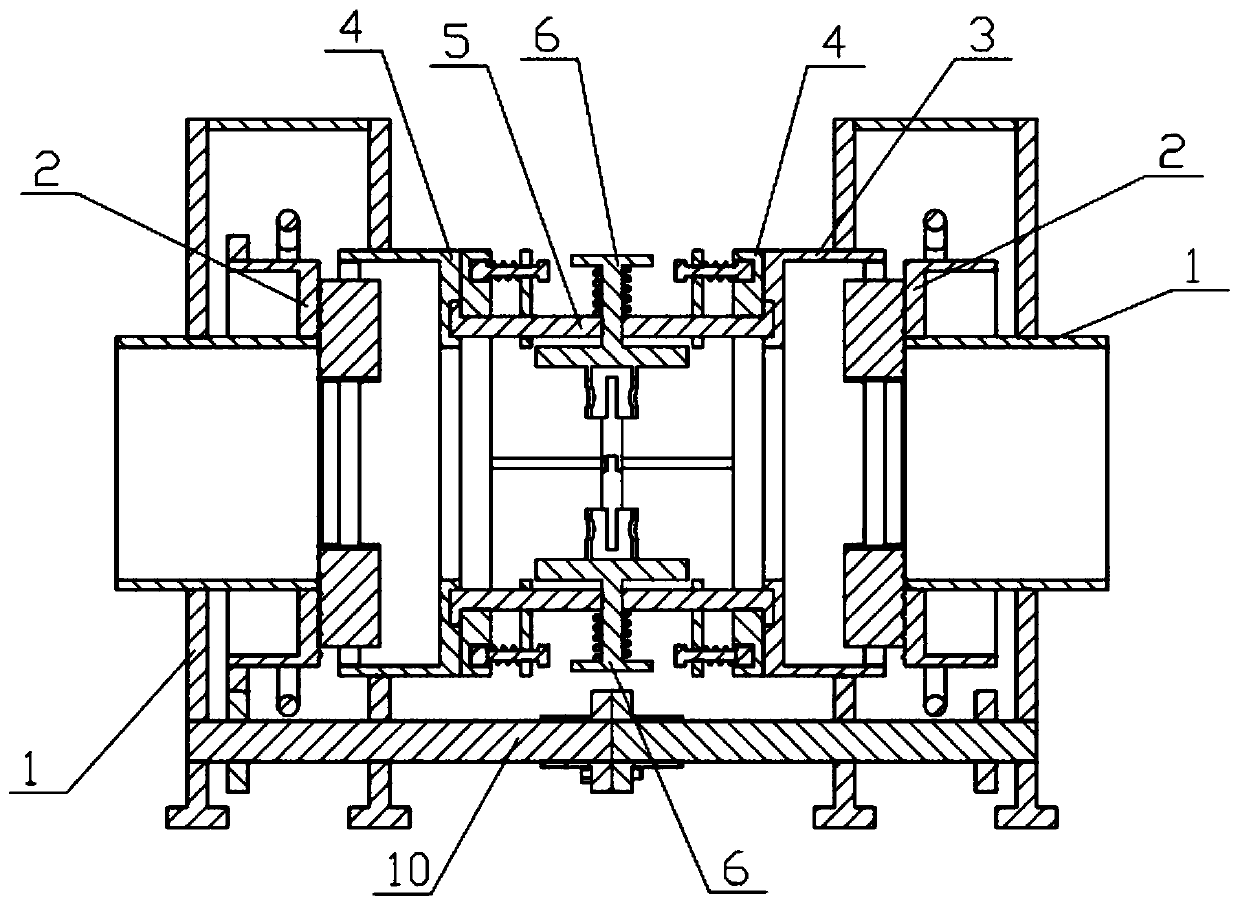

[0033] Combine below Figure 1-12 Describe this embodiment, an auxiliary device for welding steel pipe columns in construction, including a side bracket 1, a rotating mechanism 2, a clamping mechanism 3, an angle plate 4, a welding bracket 5, a pushing mechanism 6, a connecting rod I7, a connecting rod II8, and a hinged column 9 and the power connection mechanism 10, the side bracket 1, the rotating mechanism 2, the clamping mechanism 3 and the angle plate 4 are all symmetrically provided with two left and right, and the two rotating mechanisms 2 are respectively rotated and connected in the two side brackets 1, and the two Two clamping mechanisms 3 are respectively fixedly connected to the inner sides of the two side brackets 1, two angle plates 4 are respectively fixedly connected to the two clamping mechanisms 3, and the welding bracket 5 and the pushing mechanism 6 are arranged symmetrically up and down. The left and right ends of each welding bracket 5 are slidably connec...

specific Embodiment approach 2

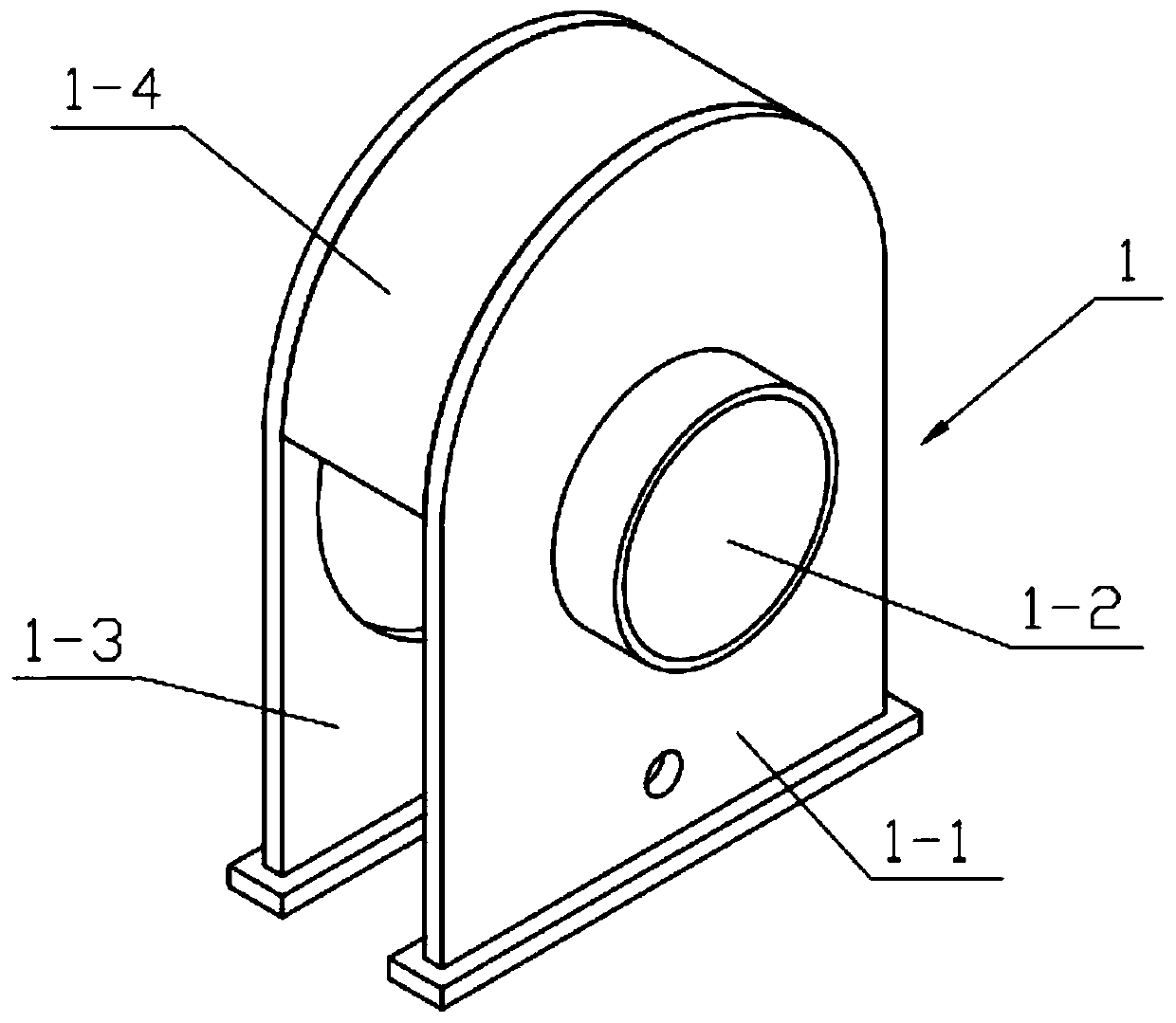

[0035] Combine below Figure 1-12 This embodiment will be described. This embodiment will further describe Embodiment 1. The side bracket 1 includes an outer plate 1-1, a support cylinder 1-2, an inner plate 1-3, and a connecting plate 1-4. The connecting plate 1-4 The two ends of the inner plate 1-3 and the upper end of the outer plate 1-1 are respectively fixedly connected, and the support cylinder 1-2 is fixedly connected to the middle end of the outer plate 1-1; when in use, the two pipes to be welded are respectively placed on the two Inside a support tube 1-2.

specific Embodiment approach 3

[0037] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the rotating mechanism 2 includes a rotating support plate 2-1, a rotating cylinder 2-2, a rotating column 2-3, a rotating handle 2-4 and a ring gear 2 -5, the rotating support plate 2-1 is provided with a spiral thread, one end of the rotating cylinder 2-2 is fixedly connected to the outer side of the rotating supporting plate 2-1, and the ring gear 2-5 is fixedly connected to the other end of the rotating cylinder 2-2 The outer side of the rotating column 2-3 is evenly arranged in a plurality of circumferential directions, the inner sides of the plurality of rotating columns 2-3 are fixedly connected to the outer side of the rotating cylinder 2-2, and the rotating handle 2-4 is fixedly connected to the plurality of rotating columns 2 -3 on the outside, the two rotating support plates 2-1 are respectively rotatably connected to the inner sides of the two sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com