Efficient dicing machine

A dicing machine, high-efficiency technology, applied in metal processing and other directions, can solve the problems of adjusting the overall thickness of the material, low practicability, and difficulty in adjusting the cutting thickness of the cutting edge slicing knife, etc., to achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

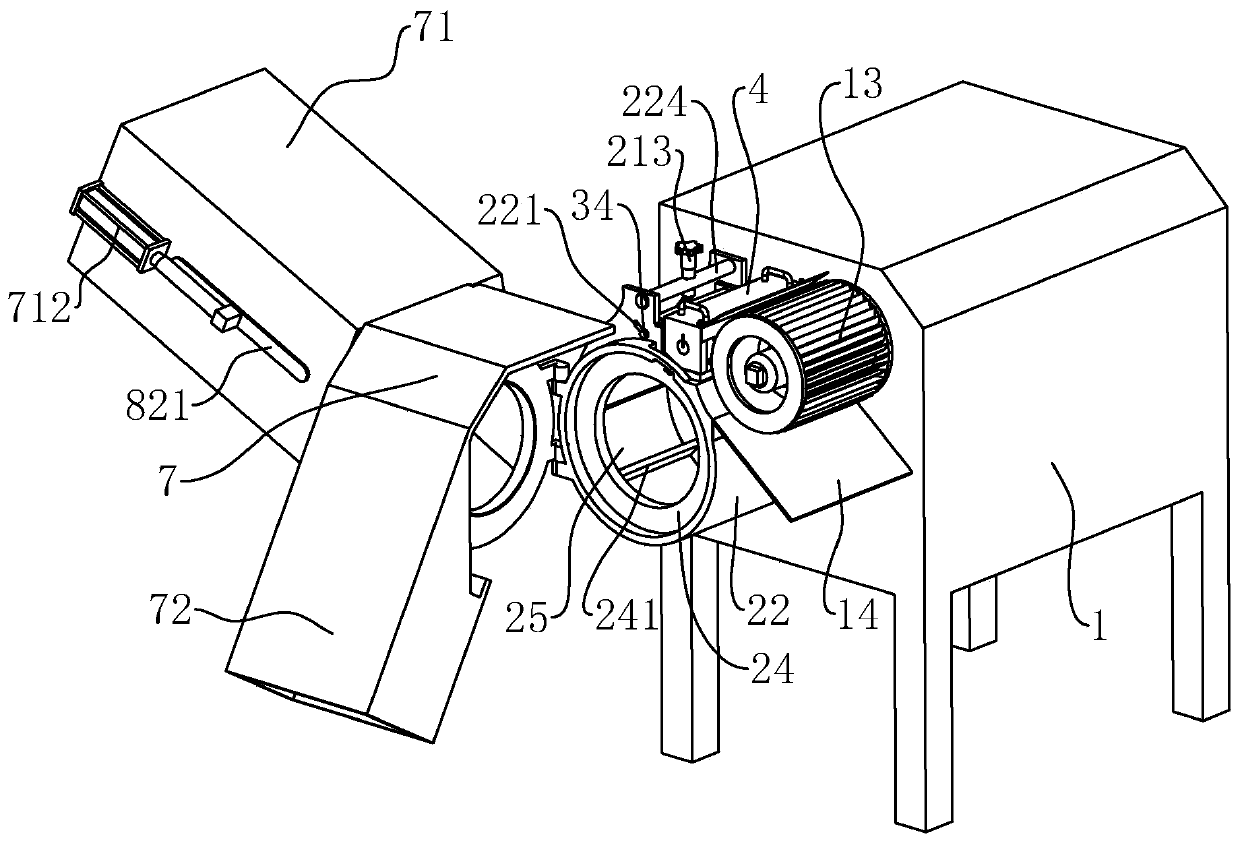

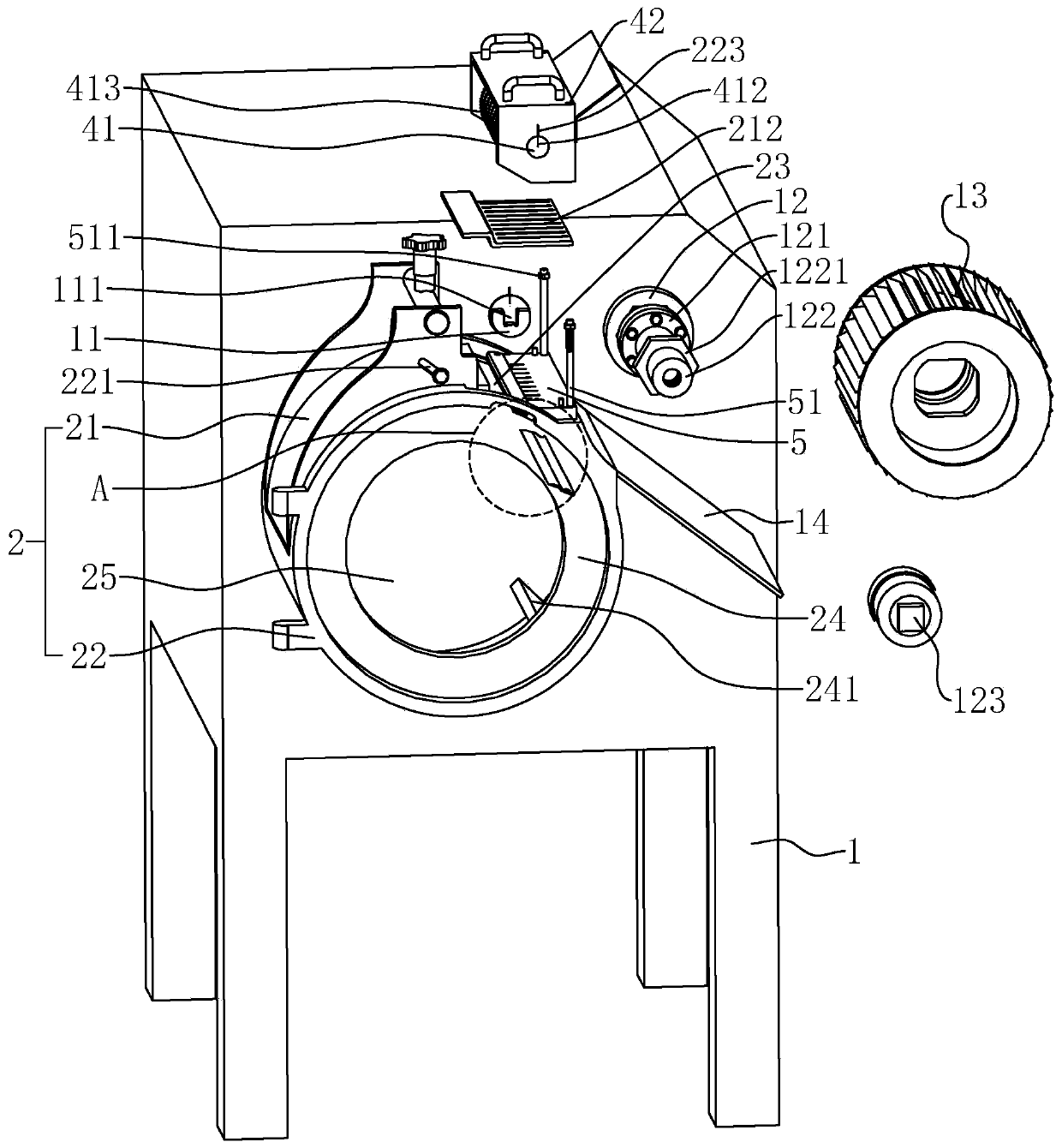

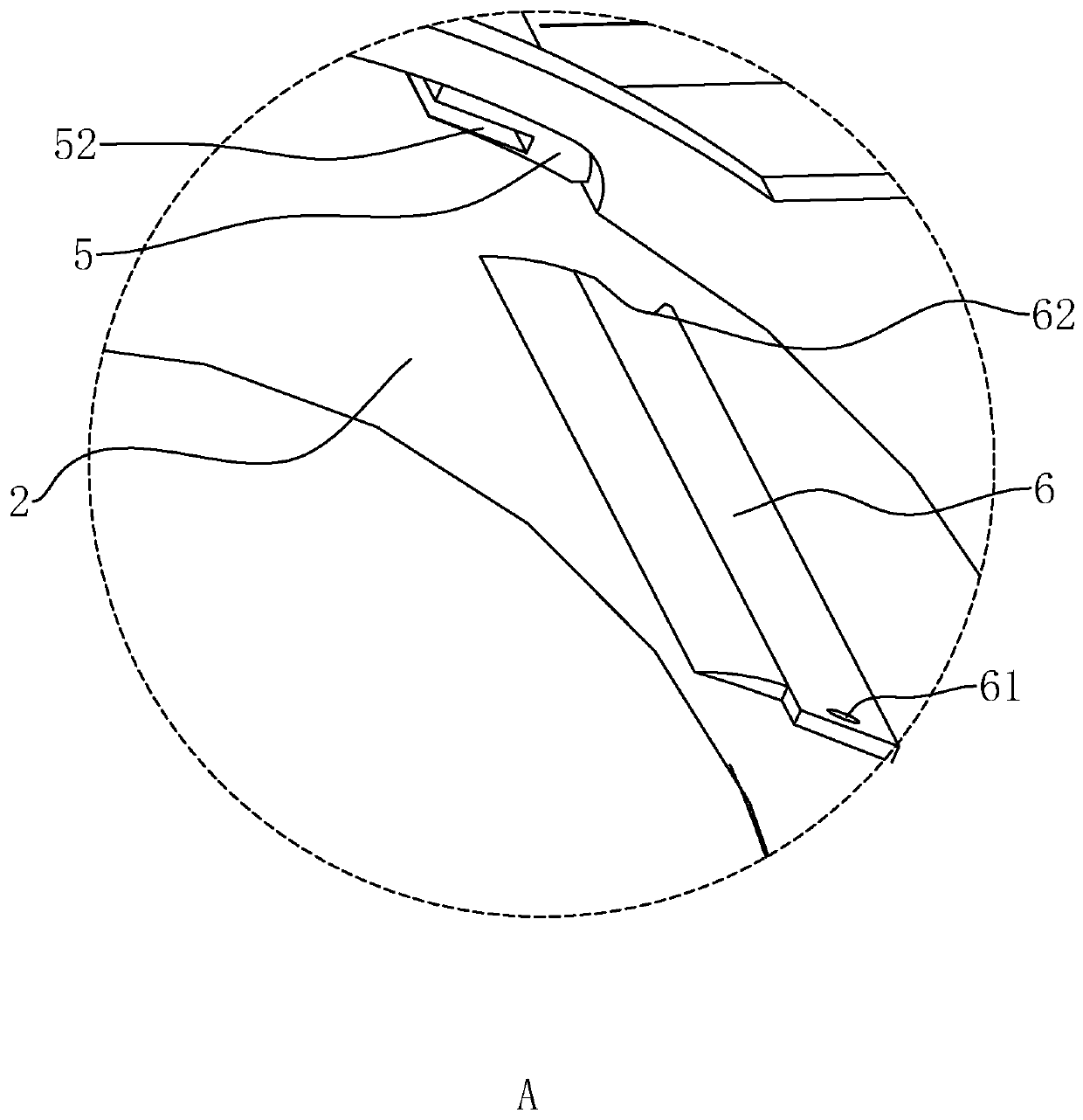

[0040] refer to figure 1 , figure 2 and image 3 , a high-efficiency dicing machine disclosed by the present invention, comprising a body 1, a feeding part, a cutting part and a discharging part are installed on one side of the body 1, and the feeding part includes a cylindrical material guide cylinder 2 and a propeller 24. The material guide cylinder 2 is fixed on the side wall of the machine body 1, and the side of the material guide cylinder 2 facing away from the machine body 1 is provided with a feed port 25, and the propeller 24 is rotatably installed inside the material guide cylinder 2. The side wall of material guide cylinder 2 is provided with strip-shaped cutout 23, and cutting portion comprises the slicer knife 6 that is installed on one side of cutout 23 and circle cutter holder 4 successively, and circle cutter holder 4 is installed by rotating shaft 41 with multiple A circle cutter 413. The discharge part includes a chopping knife cylinder 13 and a blanking ...

Embodiment 2

[0055] refer to Figure 7, the adjustment mechanism includes a worm wheel 32, a worm screw 211, two gears 33 and two arc racks 222, and the two arc racks 222 are respectively fixed on both sides of the top of the cylinder seat 22, and the center position of the arc rack 222 is the same as The hinge points of the barrel seat 22 and the upper cover 21 coincide with each other. The two gears 33 are respectively fixed on the two ends of the elevating rod 3 , and the gears 33 on the same side mesh with the arc-shaped rack 222 . The worm wheel 32 is fixed on the middle part of the lifting rod 3 , the worm screw 211 is rotatably mounted on the top of the upper cover 21 , and the worm screw 211 and the worm wheel 32 mesh with each other. Turning the worm 211 can drive the worm wheel 32 to rotate, and the worm wheel 32 can drive the lifting rod 3 and the gear 33 to rotate, and the gear 33 can rotate and move on the arc-shaped rack 222, which can drive the upper cover 21 to turn around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com