A kind of 3D shaping device and production method of non-woven fabric for automobile seat foam

A technology for car seats and shaping devices, which is applied in the field of non-woven fabrics, can solve the problems of low production efficiency, complicated procedures, and the inability to produce 3D-shaped products with negative angles, so as to avoid secondary processing and simplify the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

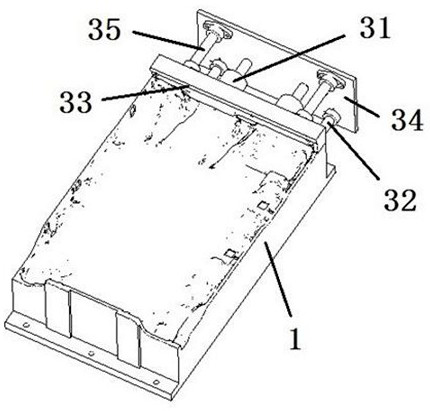

[0023] A 3D shaping device for non-woven fabrics for car seat foaming, comprising: an upper mold 1, a lower mold 2 and a negative-angle side pressing mold device;

[0024] like figure 1 As shown, a plurality of concave structures are distributed on one side of the upper mold 1;

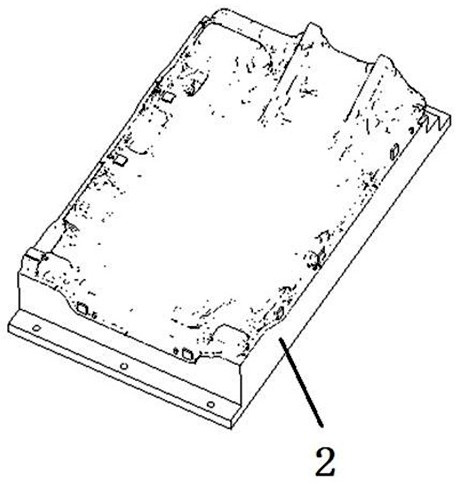

[0025] like figure 2 As shown, a plurality of convex structures are distributed on one side of the lower mold 2;

[0026] The upper and lower positions of the upper mold 1 and the lower mold 2 are opposite to each other, and are used in conjunction;

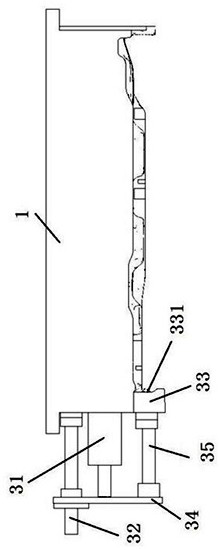

[0027] The negative angle side pressing die device is connected to one side of the upper die 1 and the lower die 2, and mainly includes: a telescopic unit 31, a guide rod 32, a negative angle pressing block 33, a moving plate 34 and a connecting rod 35;

[0028] like figure 1 As shown, the moving plate 34 is located on one side of the upper mold 1, and is parallel to the upper mold 1;

[0029] One end of the upper mold 1 is connected with two guide...

Embodiment 2

[0033] The 3D shaping device for non-woven fabrics for automobile seat foaming as described in the first embodiment, the shaping method is as follows:

[0034] ①In the initial state, the negative angle pressing block 33 is far away from the upper die 1 .

[0035] ② In the next step, the non-woven fabric is transferred between the upper mold 1 and the lower mold 2, and the pressing between the upper mold 1 and the lower mold 2 is controlled, and the non-woven fabric is shaped at this time.

[0036] ③ In the next step, the telescopic unit 31 pushes the moving plate 34 and drives the negative angle pressing block 33 to run toward the lower mold 2. When the negative angle pressing block 33 is completely pressed with the lower mold 2, it stops, and the non-woven fabric will form the required negative angle structure.

[0037] ④ In the next step, wait for a certain amount of time. After the non-woven fabric is completely formed, the negative angle pressing block 33 moves in the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com