Engineering vehicle and steering mechanism and steering control system thereof

A technology of steering mechanism and controller, which is applied in steering mechanism, fluid steering mechanism, steering tie rod, etc. It can solve the problems of complex adjustment, long steering tie rod, and small hydraulic power assist force, so as to ensure driving safety and improve ground clearance , the effect of increasing the steering torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]A steering mechanism of an engineering vehicle, comprising a front axle steering mechanism and a rear axle steering mechanism;

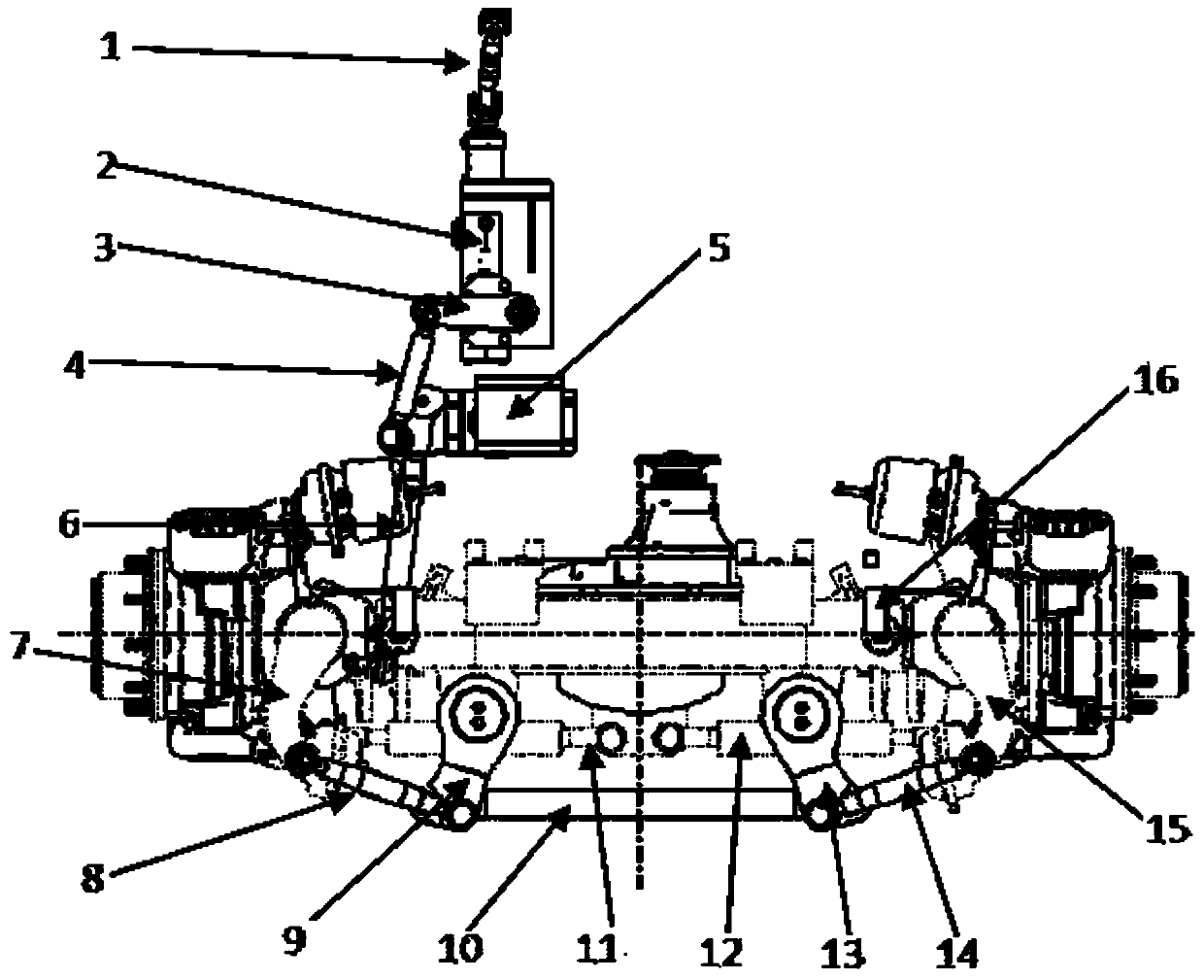

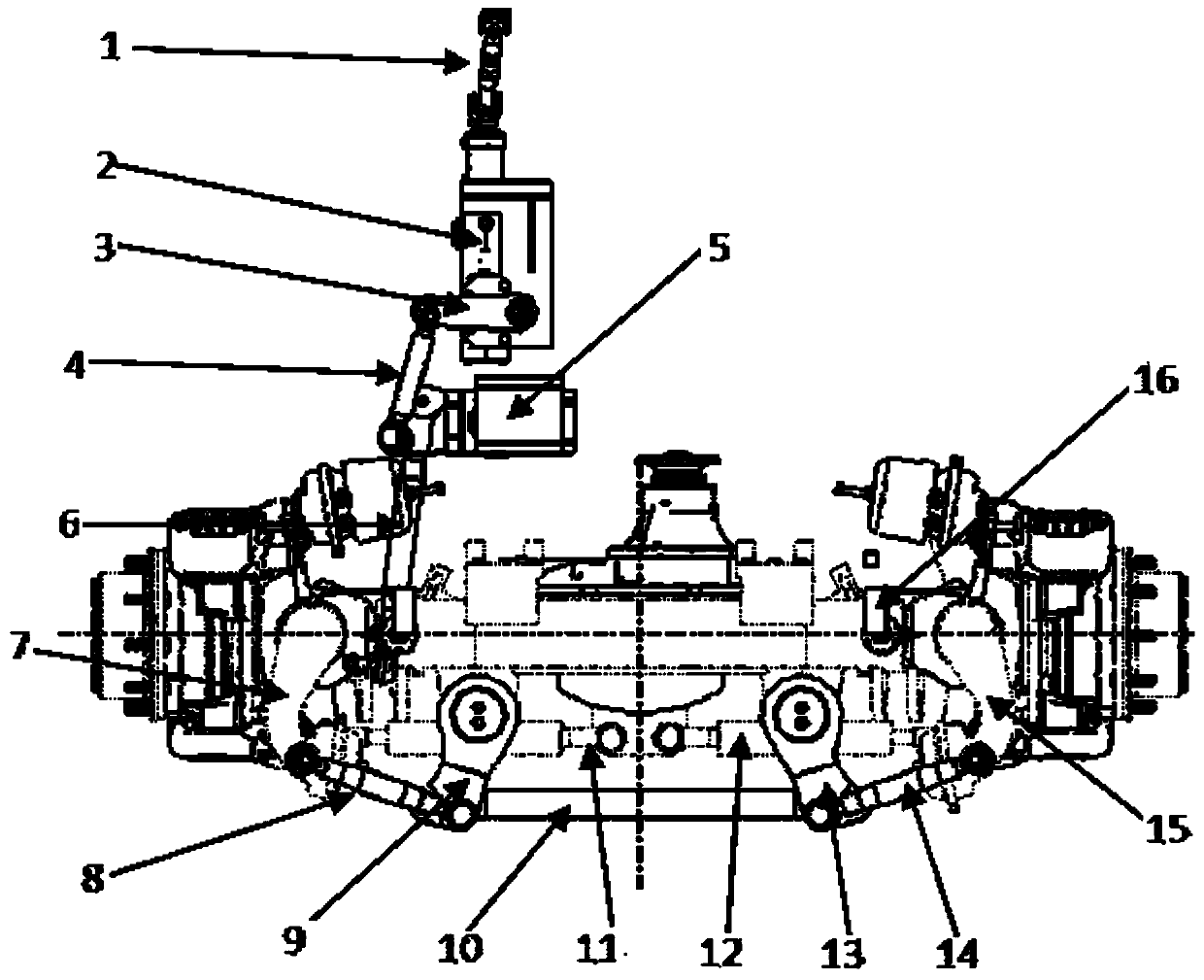

[0041] Such as figure 1 As shown, the front axle steering mechanism includes a steering transmission shaft 1, a steering gear 2, a steering drop arm 3, a first transmission steering rod 4, a transmission steering rocker arm 5, a second transmission steering rod 6, a first wheel steering knuckle arm 7, The first steering rod 8, the first rod steering rocker 9, the front axle adjustable steering rod 10, the first steering cylinder 11, the second steering cylinder 12, the second rod steering rocker 13, the second steering rod 14, the second Wheel steering knuckle arm 15, front axle angular displacement sensor 16;

[0042] In some embodiments, such as figure 1 As shown, the front axle steering mechanism includes the first wheel knuckle arm 7, the first steering rod 8, the first rod steering rocker 9, the front axle adjustable steering rod 10, the...

Embodiment 2

[0055] An engineering vehicle includes the steering mechanism described in Embodiment 1.

Embodiment 3

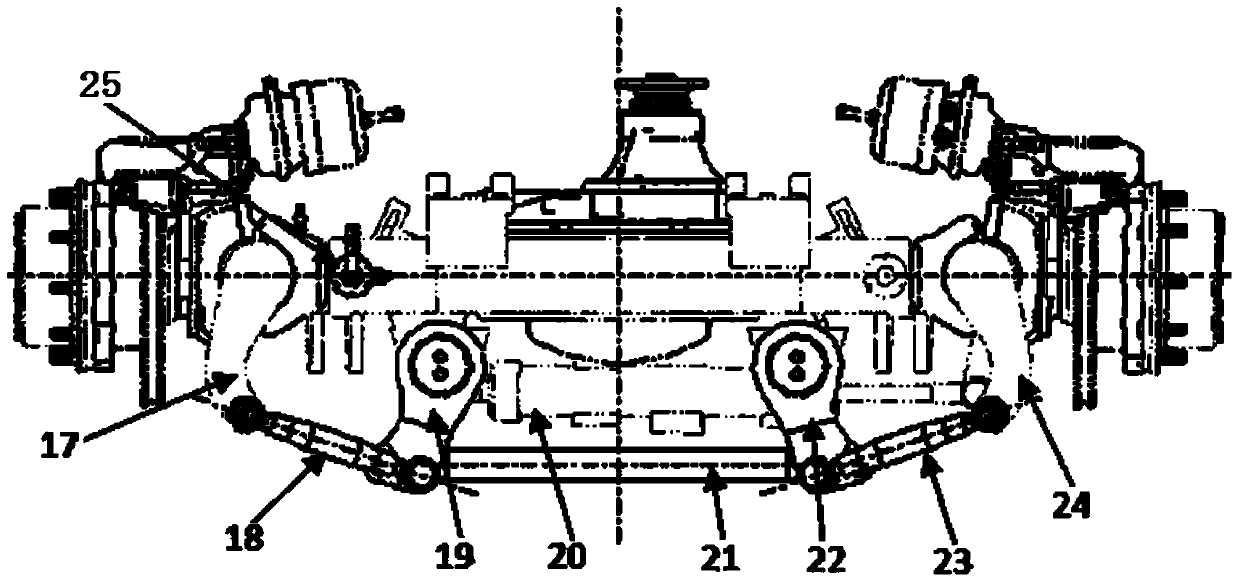

[0057] A steering control system for an engineering vehicle, comprising the steering mechanism described in Embodiment 1, and also comprising a controller, a front axle angular displacement sensor 16, a rear axle angular displacement sensor 25, a steering valve group, a front axle angular displacement sensor 16, a rear axle The angular displacement sensor 25 and the steering valve group are respectively connected with the controller;

[0058] The front axle angular displacement sensor 16 is used to detect the steering angle of the rear wheel and send it to the controller;

[0059] The rear axle angular displacement sensor 25 is used to detect the steering angle of the rear wheel and send it to the controller;

[0060] The control end of the steering valve group is connected to the controller, and is used to receive control instructions from the controller to control the action of the rear axle steering lock integrated oil cylinder 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com