Obstacle crossing robot

A robot and stepper motor technology, applied in the field of robots, can solve the problems of insignificant obstacle crossing effect, and the robot cannot really assist or replace manual work, etc., to achieve strong obstacle crossing performance, enhance stability and firmness, and reduce the The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

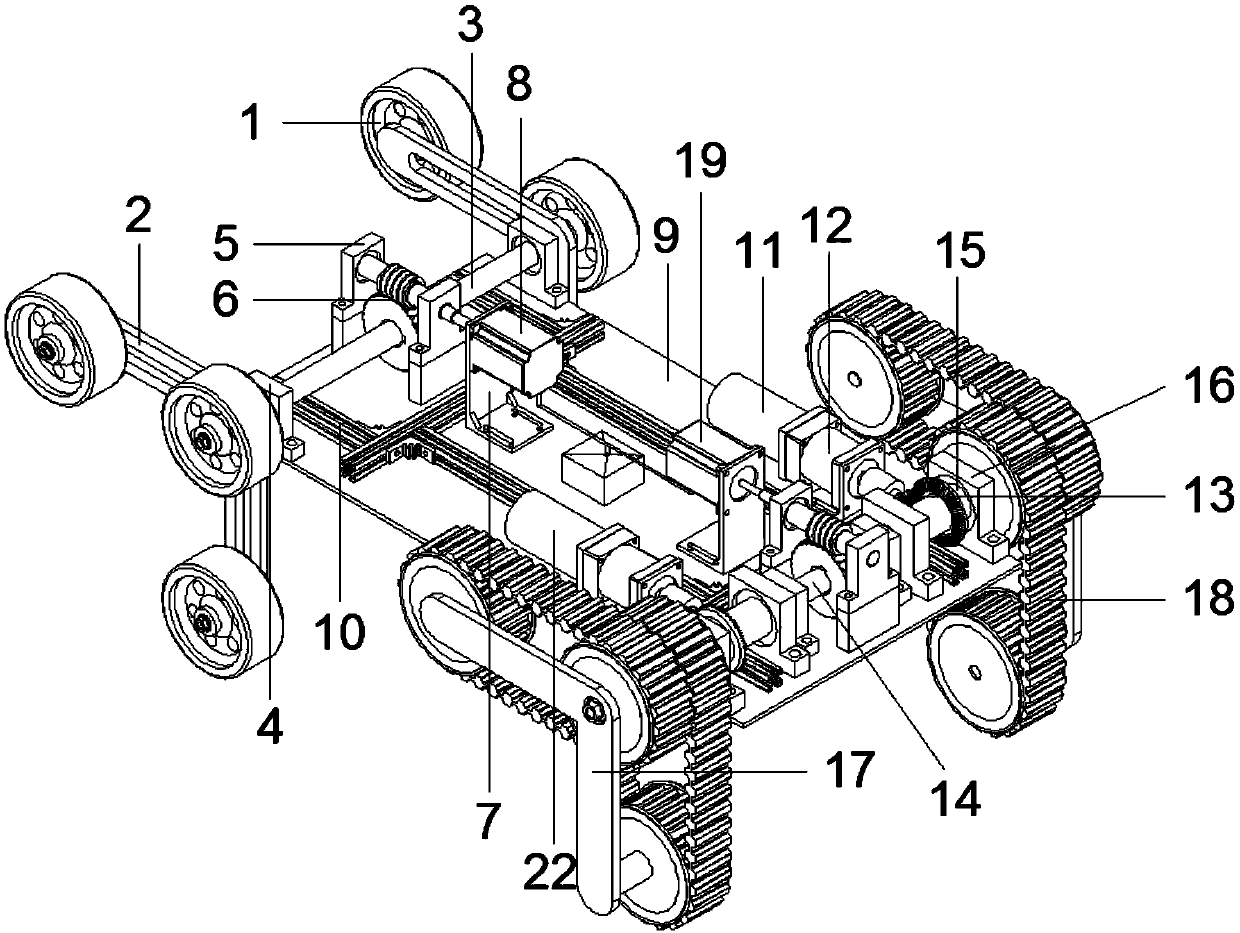

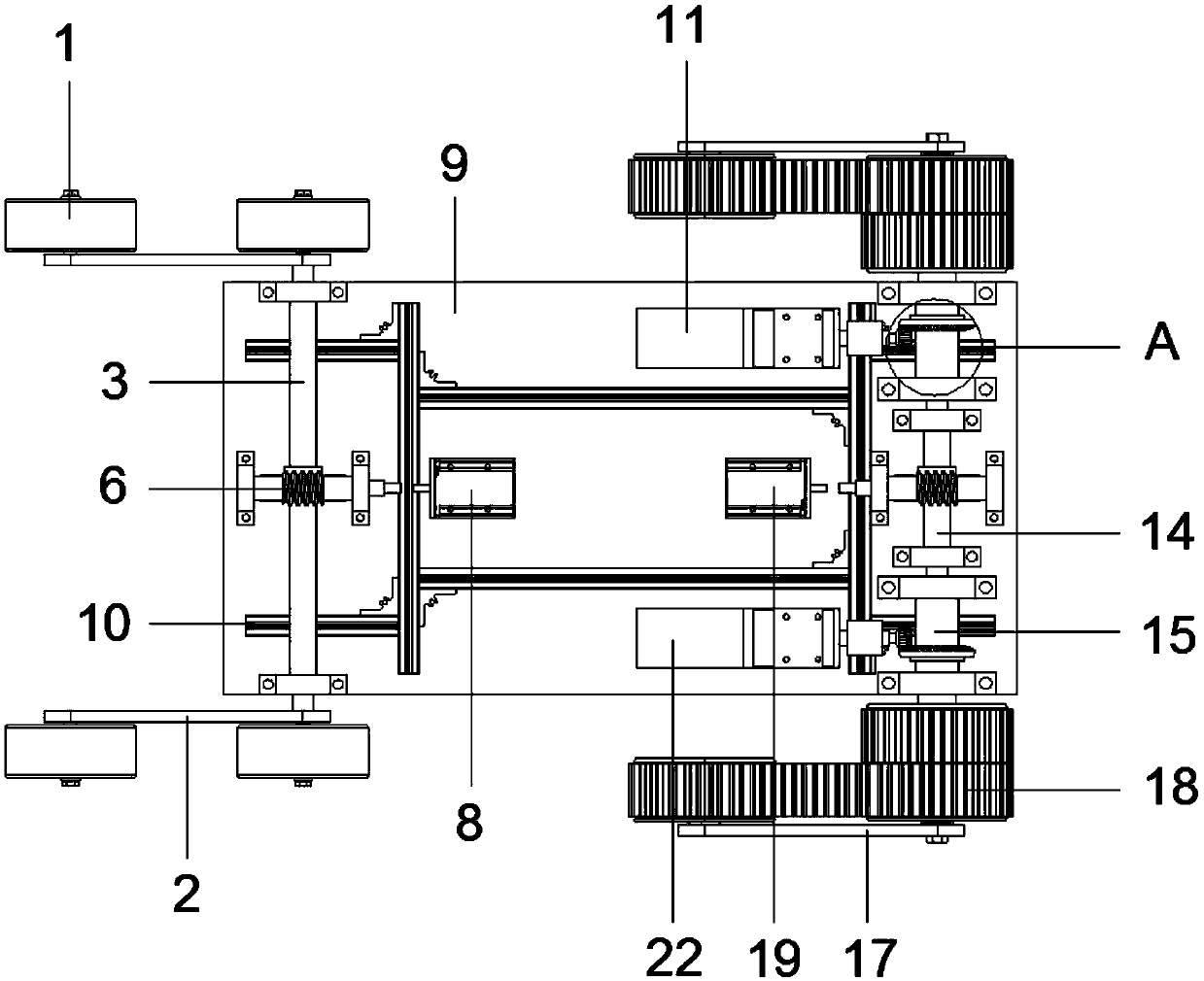

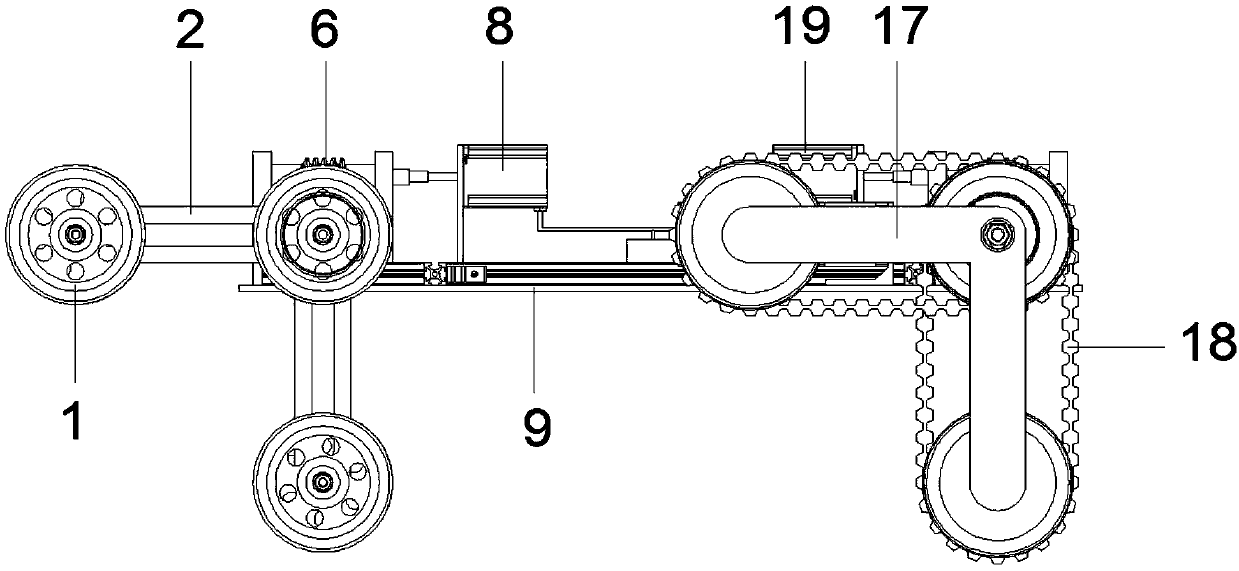

[0027]An obstacle-crossing robot, comprising: a front wheel 1, a front right-angle leg mechanism 2, a front shaft 3, a front shaft fixing seat 4, a T-shaped bearing seat 5, a worm gear transmission mechanism 6, a motor bracket 7, and a first stepping motor 8 , base plate 9, rib 10, first DC motor 11, planetary reducer 12, bevel gear transmission mechanism 13, transmission rod 14, rear rotating shaft 15, rear rotating shaft fixing seat 16, rear right-angle leg support 17, track wheel 18, the first Two stepper motors 19, small bevel gears 20, large bevel gears 21, the second DC motor 22; reinforcing ribs 10 are installed on the top of the base plate 9, and the reinforcing ribs 10 are connected with the base plate 9 by bolts; the front rotating shaft holder 4 passes Bolts are installed on both sides of the front end of the base plate 9; the front rotating shaft 3 is embedded and installed on the front rotating shaft fixing seat 4, and the front rotating shaft 3 and the front rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com