Mounting equipment for machine-room-less elevator

A machine room-less elevator and equipment installation technology, which is applied to the lifting equipment, transportation and packaging in mines, can solve the problems of low operating efficiency, slow construction progress, and high labor intensity, and achieve low cost, high safety, and structural integrity. lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

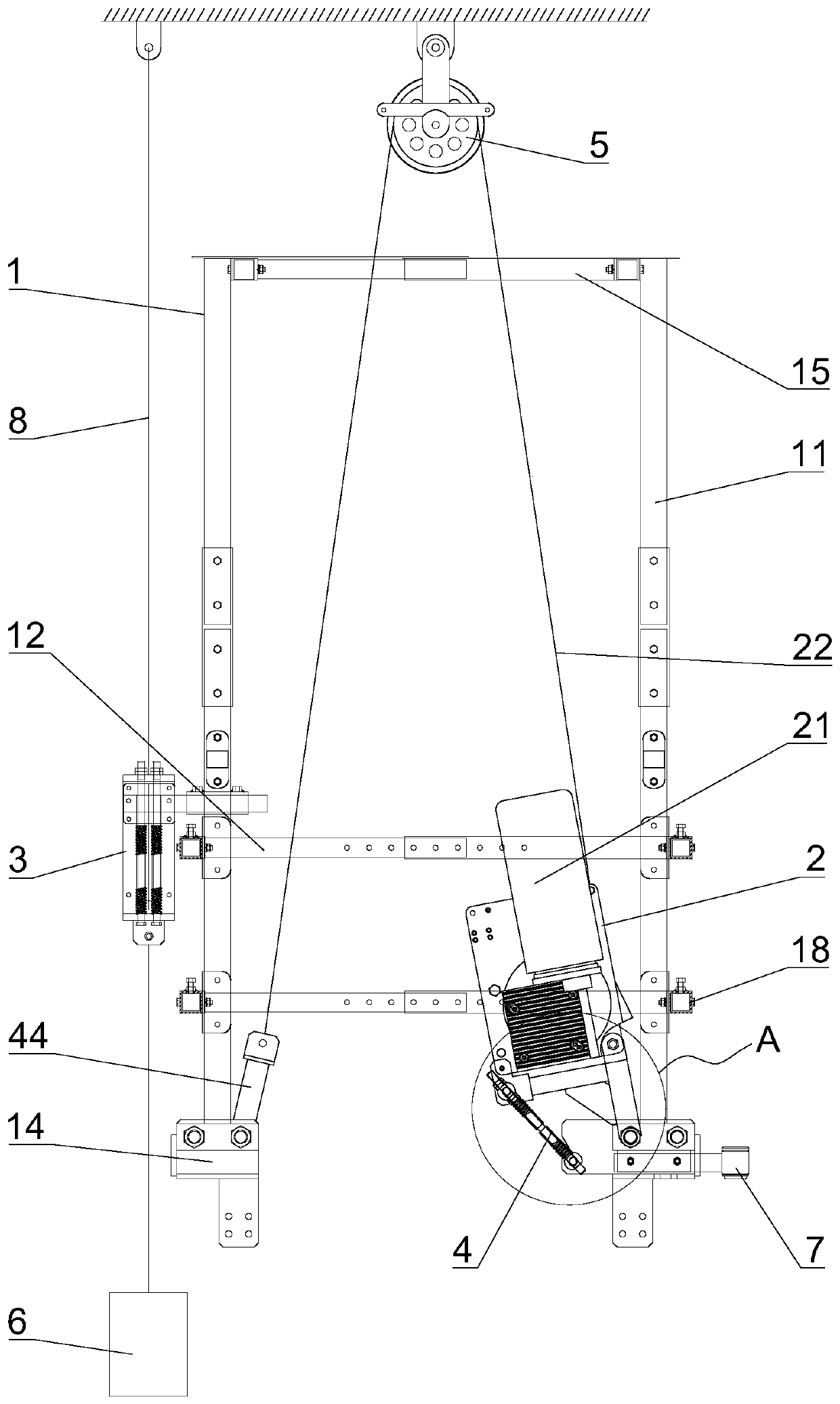

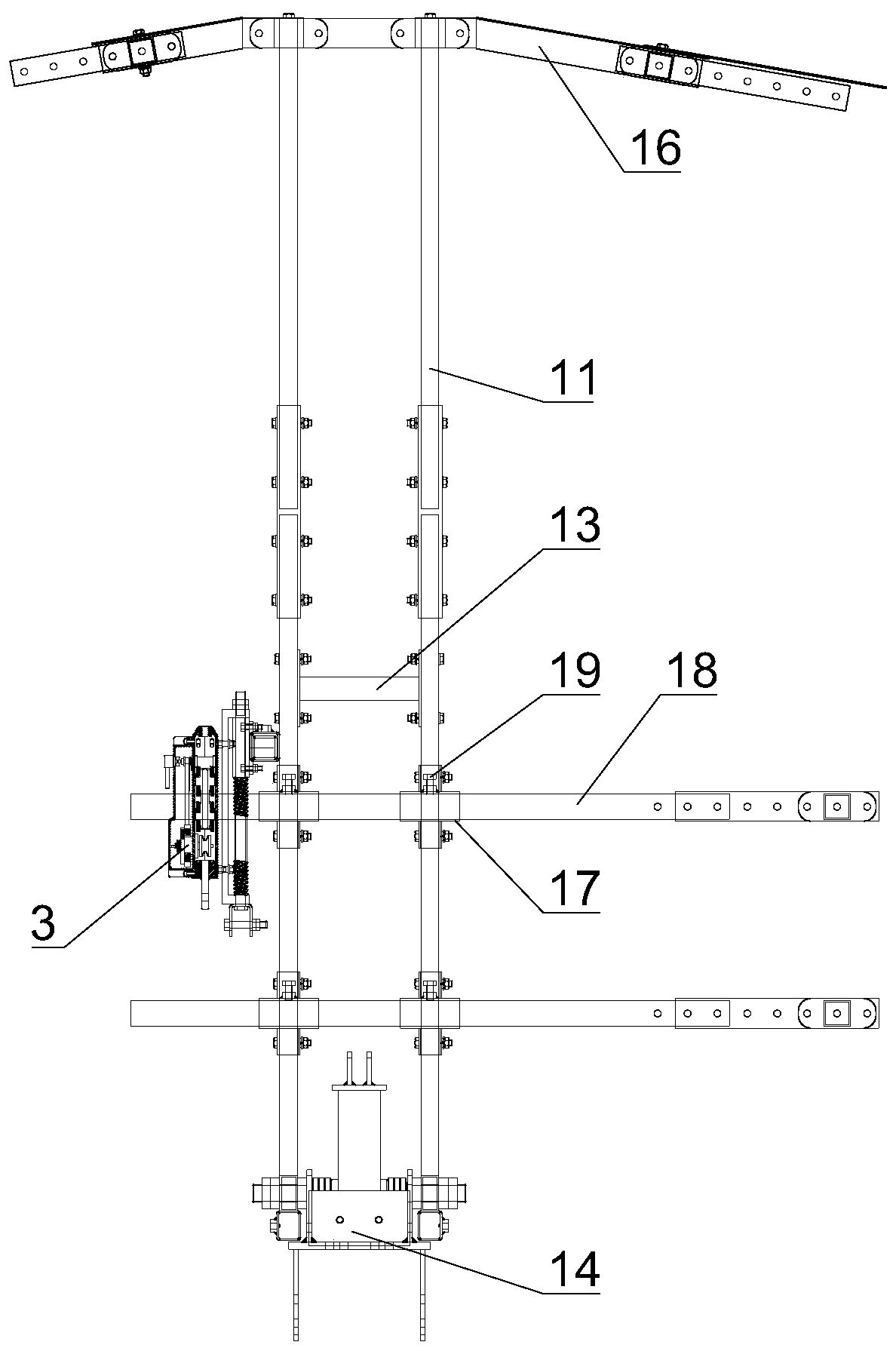

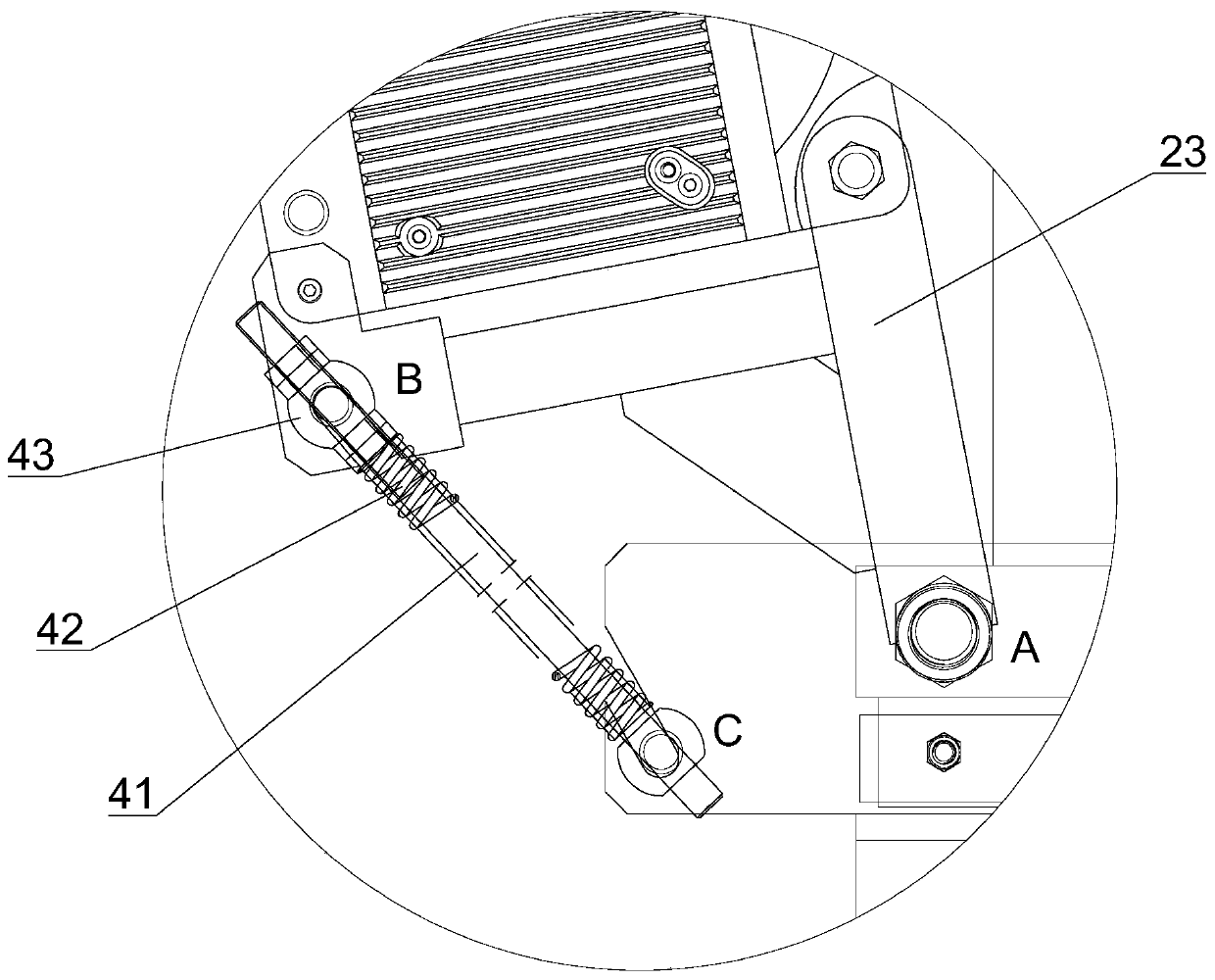

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0025] see Figures 1 to 3 As shown, this embodiment provides a machine room-less elevator installation device, acting on the top of the elevator car, which includes a support frame 1 , a power lifting device 2 , a safety protection device 3 and a compensation device 4 . The elevator car moves up and down on the guide rails of the hoistway, a safety wire rope 8 is arranged in the hoistway, and a guide wheel 5 is arranged on the top of the hoistway.

[0026] The support frame 1 includes four uprights 11, wherein the two uprights 11 in the column are fixedly connected by a connecting column 13, and the bottoms of the two uprights 11 in the same column are all provided with mounting seats 14, and the two mounting bases 14 are connected with the elevator car. The top beams are fixedly connected, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com