Bacterial cellulose composite membrane for medical dressings and preparation method thereof

A technology of bacterial cellulose and composite membrane, applied in the fields of medical science, bandages, absorbent pads, etc., can solve the problems of poor antibacterial performance, single structure, poor functionality, etc., and achieve improved antibacterial properties, many reaction sites, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

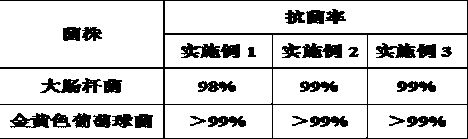

Embodiment 1

[0046] S1: Prepare materials:

[0047] Weigh bacterial cellulose, sodium periodate, chitosan, polyvinyl alcohol, silver nitrate solution, graphene oxide solution, crosslinking agent, sodium thiosulfate, isopropanol, sodium hydroxide and chloroacetic acid in proportion, spare;

[0048] Weigh acrylamide, N,N-methylenebisacrylamide, ammonium persulfate, sodium alginate, calcium chloride and collagen in proportion, and set aside;

[0049] S2: Preparation of modified bacterial cellulose:

[0050] Take bacterial cellulose, dissolve it in deionized water, stir for 10 minutes, then add sodium periodate, oxidize at 50°C for 6 hours, filter with suction, wash and dry to obtain modified bacterial cellulose.

[0051] : Preparation of chitosan microspheres:

[0052] Take chitosan, dissolve chitosan in acetic acid to obtain chitosan acetic acid solution; dissolve polyvinyl alcohol in deionized water to obtain polyvinyl alcohol aqueous solution; take chitosan acetic acid solution and poly...

Embodiment 2

[0061] S1: Prepare materials:

[0062] Weigh bacterial cellulose, sodium periodate, chitosan, polyvinyl alcohol, silver nitrate solution, graphene oxide solution, crosslinking agent, sodium thiosulfate, isopropanol, sodium hydroxide and chloroacetic acid in proportion, spare;

[0063] Weigh acrylamide, N,N-methylenebisacrylamide, ammonium persulfate, sodium alginate, calcium chloride and collagen in proportion, and set aside;

[0064] S2: Preparation of modified bacterial cellulose:

[0065] Take bacterial cellulose, dissolve it in deionized water, stir for 15 minutes, then add sodium periodate, oxidize at 55°C for 6.5 hours, filter with suction, wash and dry to obtain modified bacterial cellulose.

[0066] : Preparation of chitosan microspheres:

[0067] Take chitosan, dissolve chitosan in acetic acid to obtain chitosan acetic acid solution; dissolve polyvinyl alcohol in deionized water to obtain polyvinyl alcohol aqueous solution; take chitosan acetic acid solution and po...

Embodiment 3

[0076] S1: Prepare materials:

[0077] Weigh bacterial cellulose, sodium periodate, chitosan, polyvinyl alcohol, silver nitrate solution, graphene oxide solution, crosslinking agent, sodium thiosulfate, isopropanol, sodium hydroxide and chloroacetic acid in proportion, spare;

[0078] Weigh acrylamide, N,N-methylenebisacrylamide, ammonium persulfate, sodium alginate, calcium chloride and collagen in proportion, and set aside;

[0079] S2: Preparation of modified bacterial cellulose:

[0080] Take bacterial cellulose, dissolve it in deionized water, stir for 20 minutes, then add sodium periodate, oxidize at 60°C for 7 hours, filter with suction, wash and dry to obtain modified bacterial cellulose.

[0081] : Preparation of chitosan microspheres:

[0082] Take chitosan, dissolve chitosan in acetic acid to obtain chitosan acetic acid solution; dissolve polyvinyl alcohol in deionized water to obtain polyvinyl alcohol aqueous solution; take chitosan acetic acid solution and poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com