Highway bridge expansion joint cleaning device

A technology for highway bridges and cleaning devices, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of low cleaning efficiency, low utilization rate, and difficult cleaning of expansion joints, etc., and achieve the effect of thorough cleaning and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

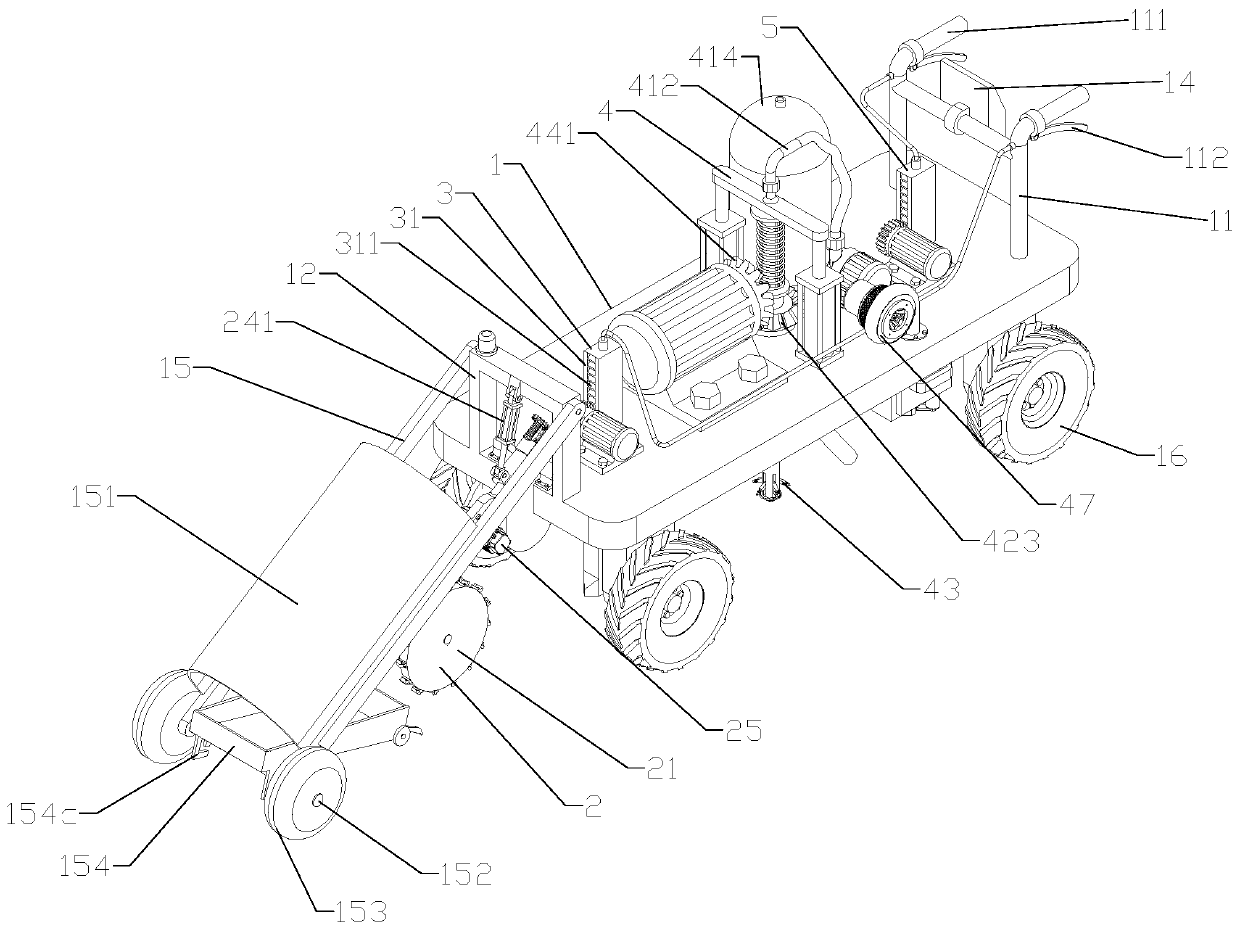

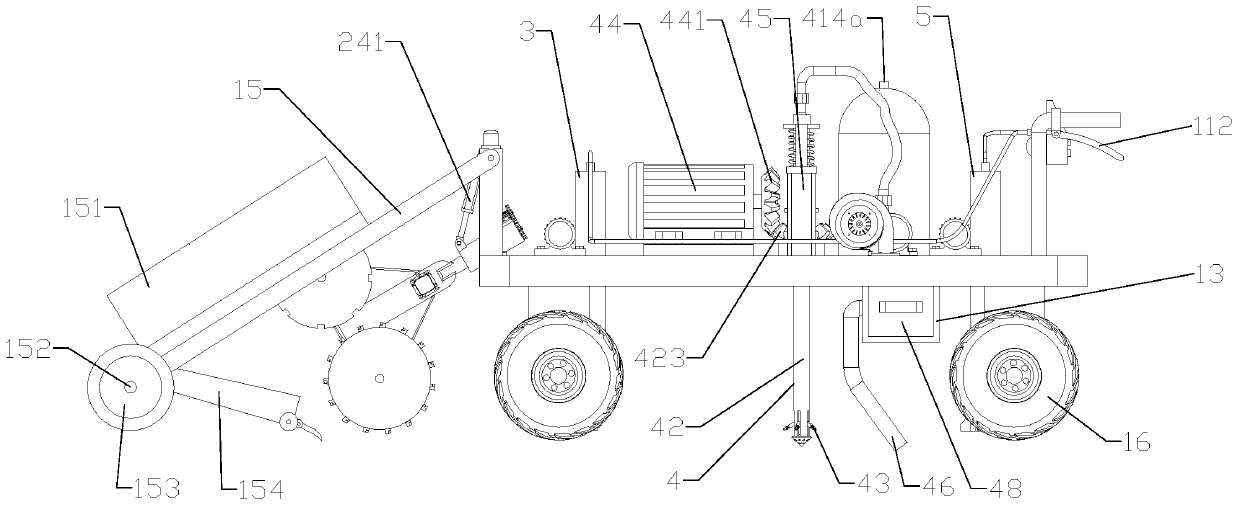

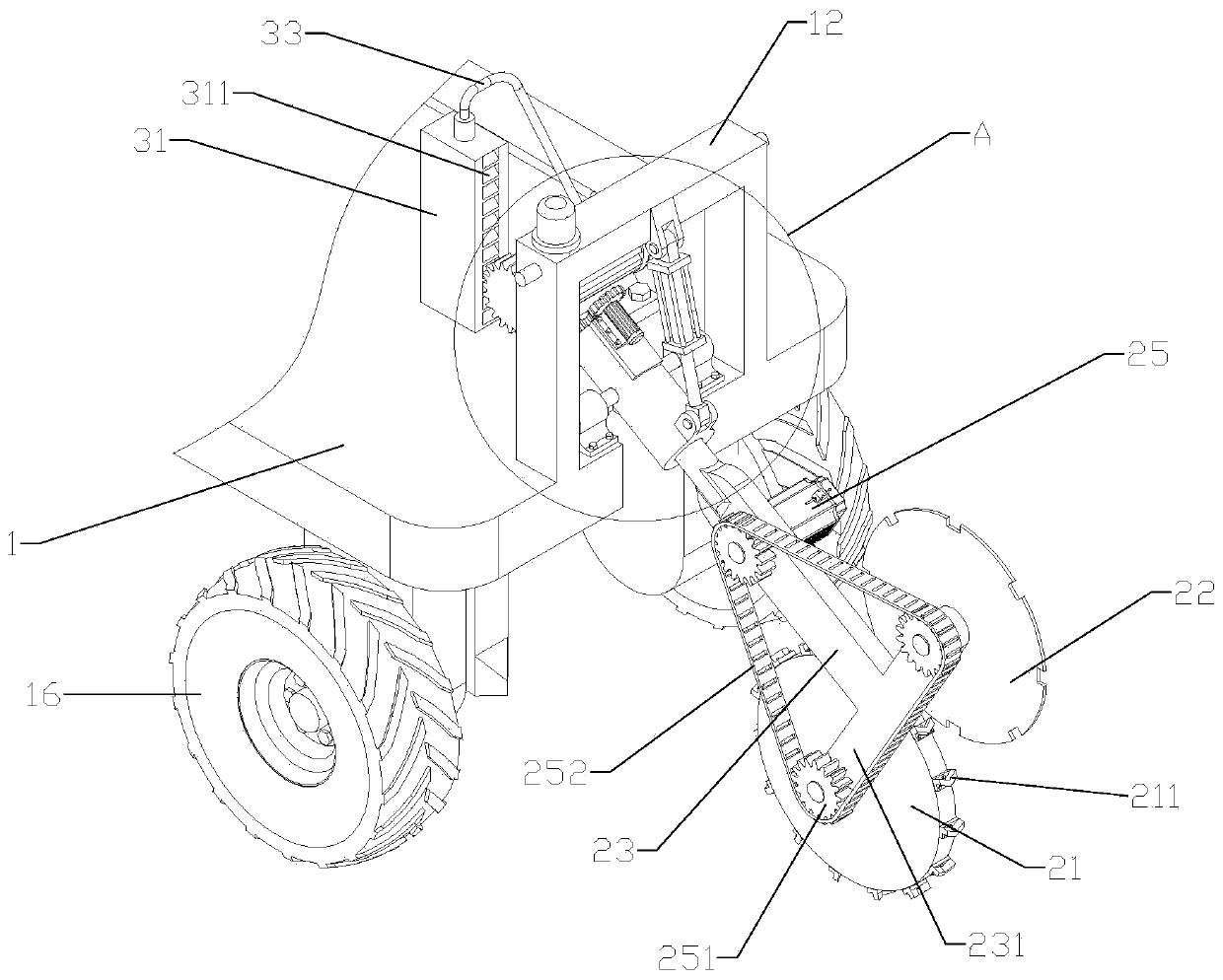

[0039] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0040] as attached figure 1 to attach Figure 19 The shown road bridge expansion joint cleaning device includes a car body 1, which is in the shape of a rectangular plate, and four traveling wheels 16 are connected to the bottom, and the car body 1 is sequentially provided with a first cleaning mechanism 2, Front righting mechanism 3, second clearing mechanism 4 and rear righting mechanism 5, the rear end of car body 1 is provided with two push rods 11, and each push rod 11 extends a handle 111 backward respectively, during use, by pushing handle 111 Promote the car body 1 to move forward. In the accompanying drawings, the walking direction of the car body 1 is the front. The first cleaning mechanism 2 includes a cleaning wheel 21, a cutting disc 22, a rotating frame 23, a fixed cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com