Horizontal fatigue testing machine

A fatigue testing machine, horizontal technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of time-consuming and labor-intensive, low test efficiency, etc., to improve test detection efficiency and save operation Time-saving, labor-saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

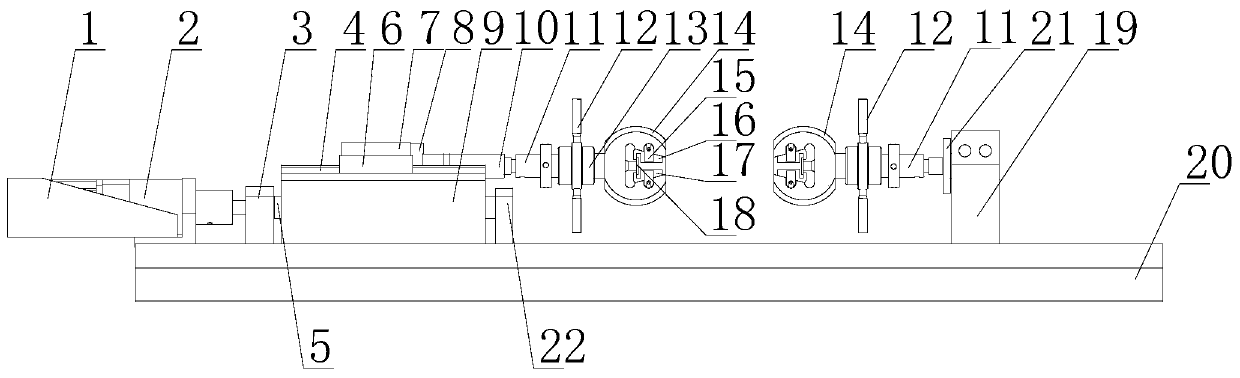

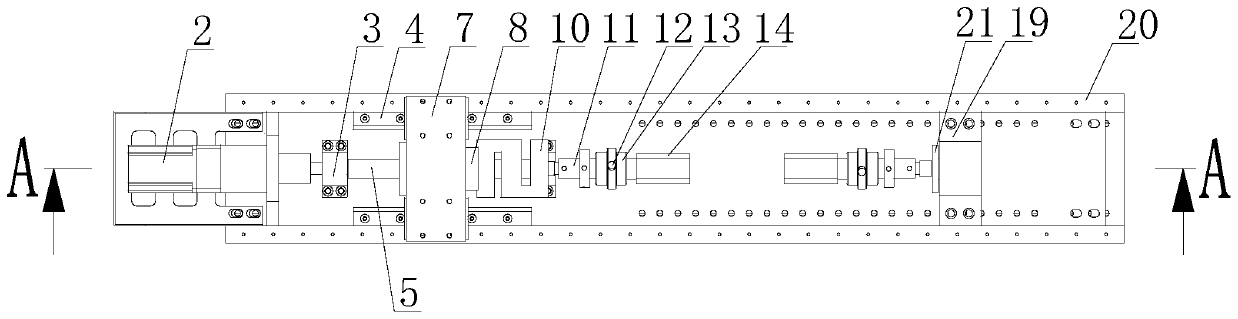

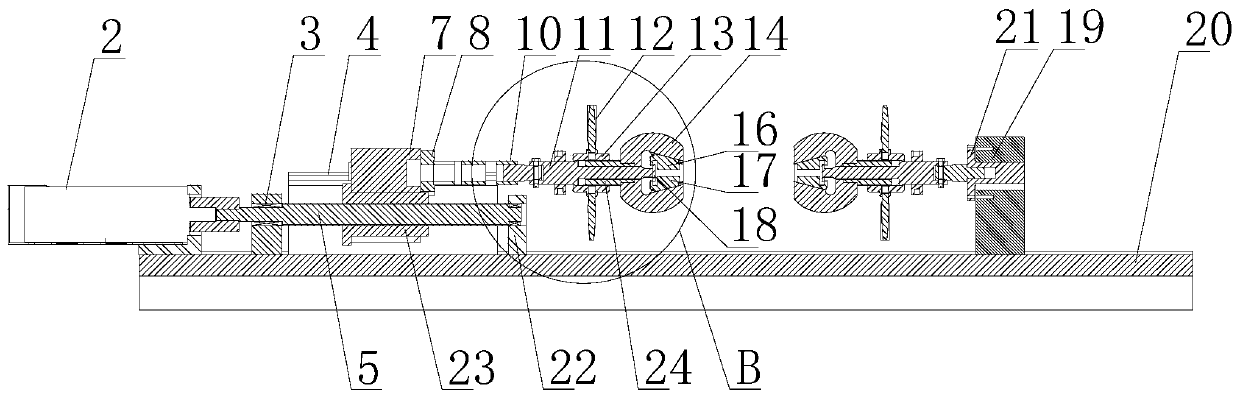

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0023] A horizontal fatigue testing machine, comprising a base 20, a left clamping mechanism installed on the base 20 and a right clamping mechanism, the left clamping mechanism is horizontally slid on the base 20 through a sliding mechanism, and the left The clamping mechanism and the sliding mechanism are connected by a tension sensor 10. The right clamping mechanism is fixedly installed on the base 20 and is on the same level as the left clamping mechanism. By setting the left clamping mechanism and the right clamping mechanism, The two ends of the film sample are clamped, and the clamping action is convenient and fast, saving time and effort; by setting the sliding mechanism and the tension sensor 10, the left cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com