Laboratory personnel unsafe behavior safety inspection method based on machine vision

A safety behavior and safety inspection technology, applied in the direction of instruments, computer components, digital data information retrieval, etc., can solve the problems of accuracy and timeliness limitations, difficulty in achieving accurate, comprehensive and efficient automated safety inspections, and achieve Accurate 24/7 checking of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

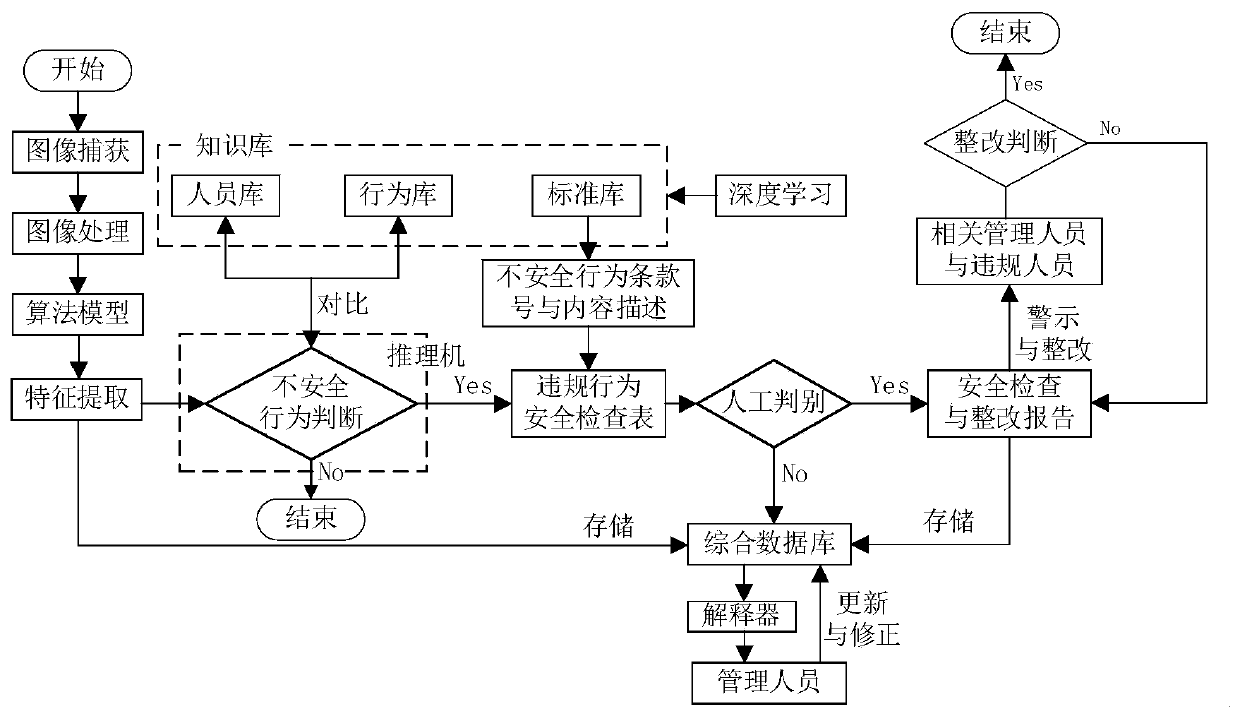

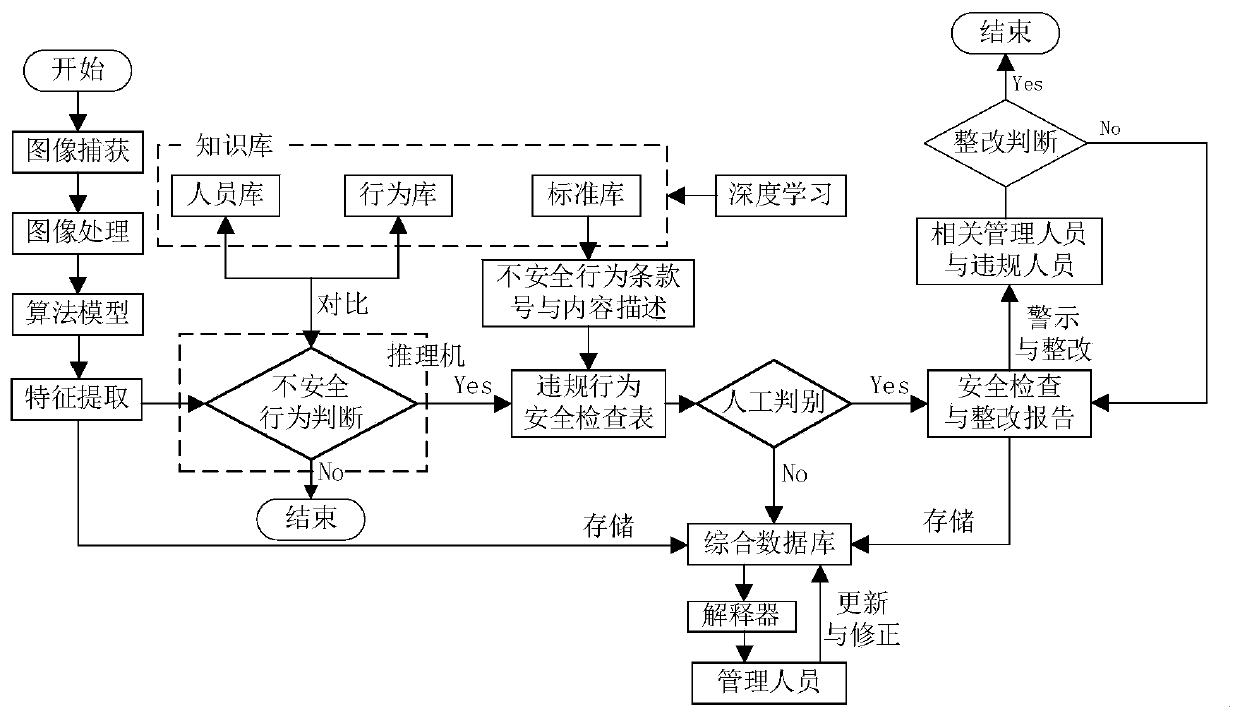

[0030] Such as figure 1 As shown, a machine vision-based safety inspection method for unsafe behaviors of laboratory personnel, the specific steps are as follows:

[0031] Step 1: Relying on the laboratory safety management system, establish a standard library and two characteristic knowledge libraries. The standard library contains a number of descriptions of safety non-conformities (unsafe behaviors) of test personnel; the two characteristic knowledge databases are "personnel database" and "behavior database". The "Personnel Database" contains images of laboratory personnel who are allowed to enter the laboratory; the personnel in the "Personnel Database" have passed the laboratory safety general education, professional laboratory safety education and experimental operation access assessment. The "Behavior Library" contains typical unsafe behavior images of laboratory p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com