Water injection pump room noise control method

A technology for noise control and pump room, applied in the direction of sound-producing equipment, instruments, etc., can solve problems such as damage to the physical and mental health of on-duty personnel and maintenance personnel, high power of the injection pump unit, and impact on the surrounding environment, etc. The effect of reasonable process, improved progress and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

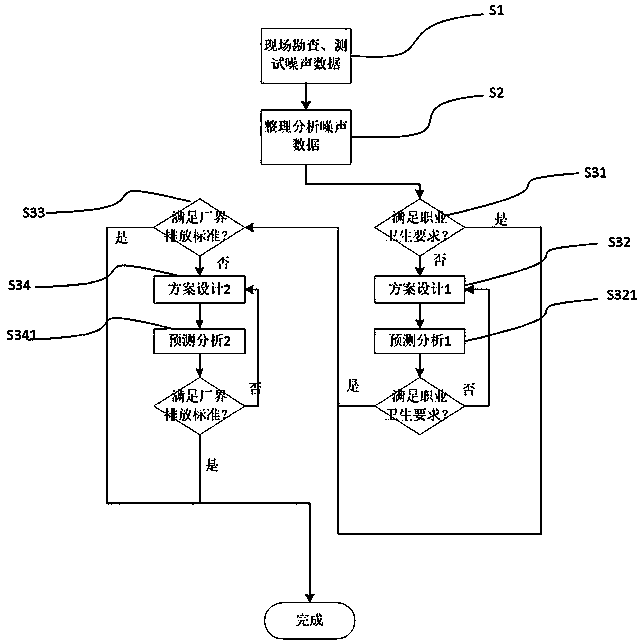

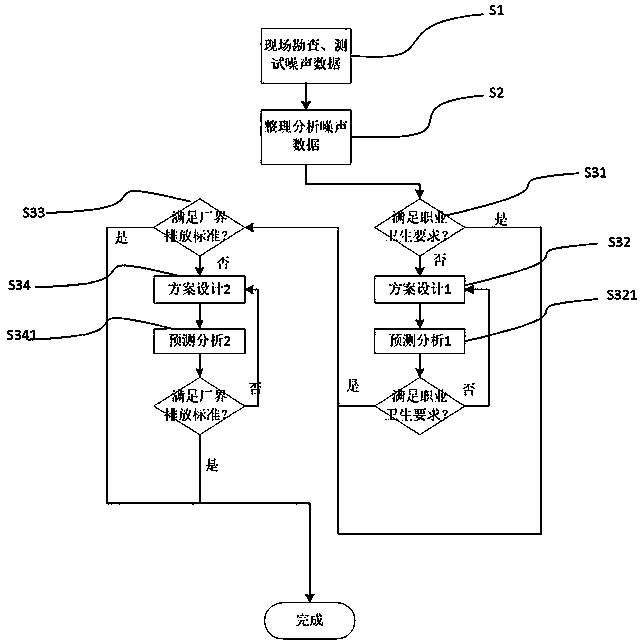

[0069] The example of the present invention relates to a noise control method for a water injection pump house, comprising the following steps:

[0070] Step S1, using the grid point layout method to test the noise inside the water injection pump room, and using the tracking method to test the exposure sound level of the staff working to obtain the noise data of the water injection pump room;

[0071] Step S2, arrange and analyze the noise data of the water injection pump house obtained in step S1, and obtain the noise status;

[0072] Step S3, judging whether the noise value meets the factory boundary environmental noise emission standards and occupational health requirements;

[0073] if yes, complete;

[0074] If not, determine the corresponding superscalar, and design the noise reduction scheme.

[0075] The control method of the present invention uses the grid layout method to test the noise inside the water injection pump room and the tracking method to test the exposu...

Embodiment approach

[0081] As an implementation manner, step S1 specifically includes:

[0082] Carry out on-site investigation, use the grid layout method to test the noise inside the water injection pump room, arrange points around the water injection pump unit in the water injection pump room to test the noise value of the equipment, and use the tracking method to test the exposure sound level of the workers' inspection contact for occupational health , Set up noise measuring points lined up outside the factory building and at the wall of the factory boundary to test the noise outside the factory building and the noise at the factory boundary.

[0083] As an implementation, in the step S1, use a sound level meter to test the noise value of the water injection pump unit, the water pump room, the duty room and the water injection pump room corresponding to the factory boundary, and determine the noise factory boundary emission standards and occupational hygiene standards implemented in the area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com