Fish viscera removing and cleaning device

A cleaning device and fish technology, applied in fish cleaning/descale, processing fish, slaughtering, etc., can solve the problems of expensive equipment imports, damage to fish, and affect processing efficiency, etc., to achieve intelligent decontamination processing, prevent Slippery, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation of the present invention will be further described in conjunction with the following drawings and technical solutions.

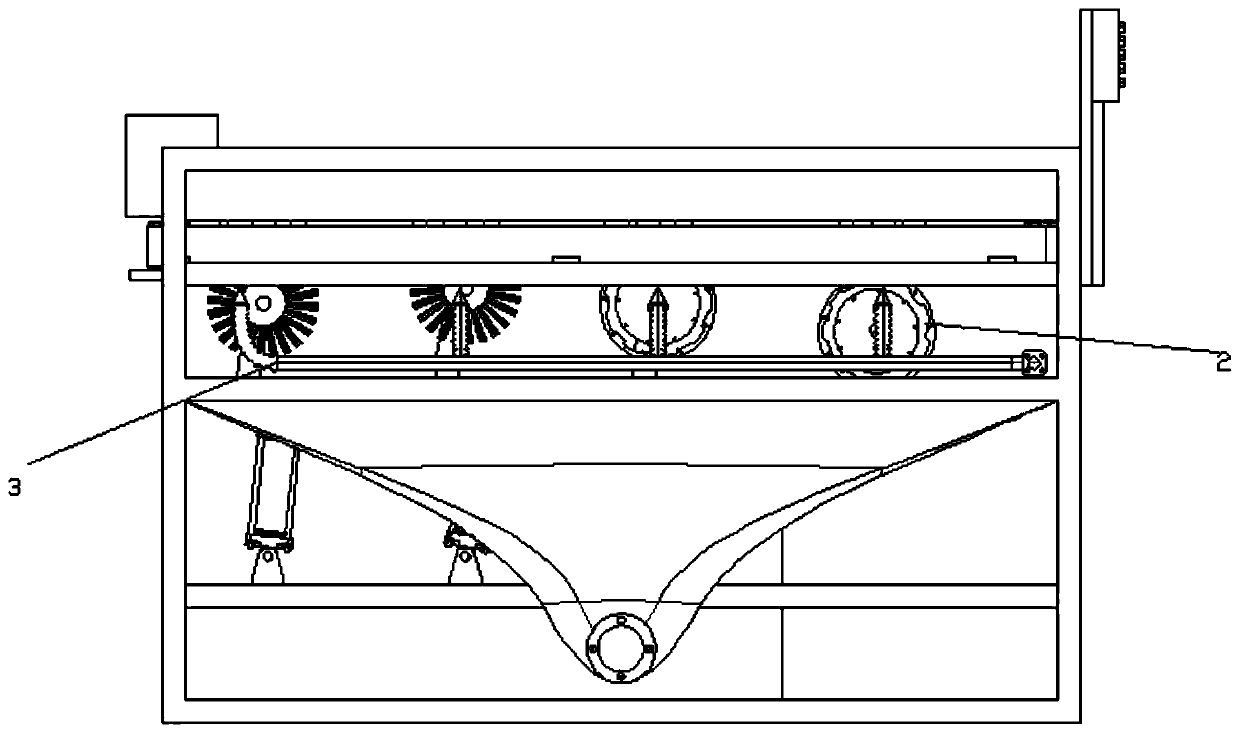

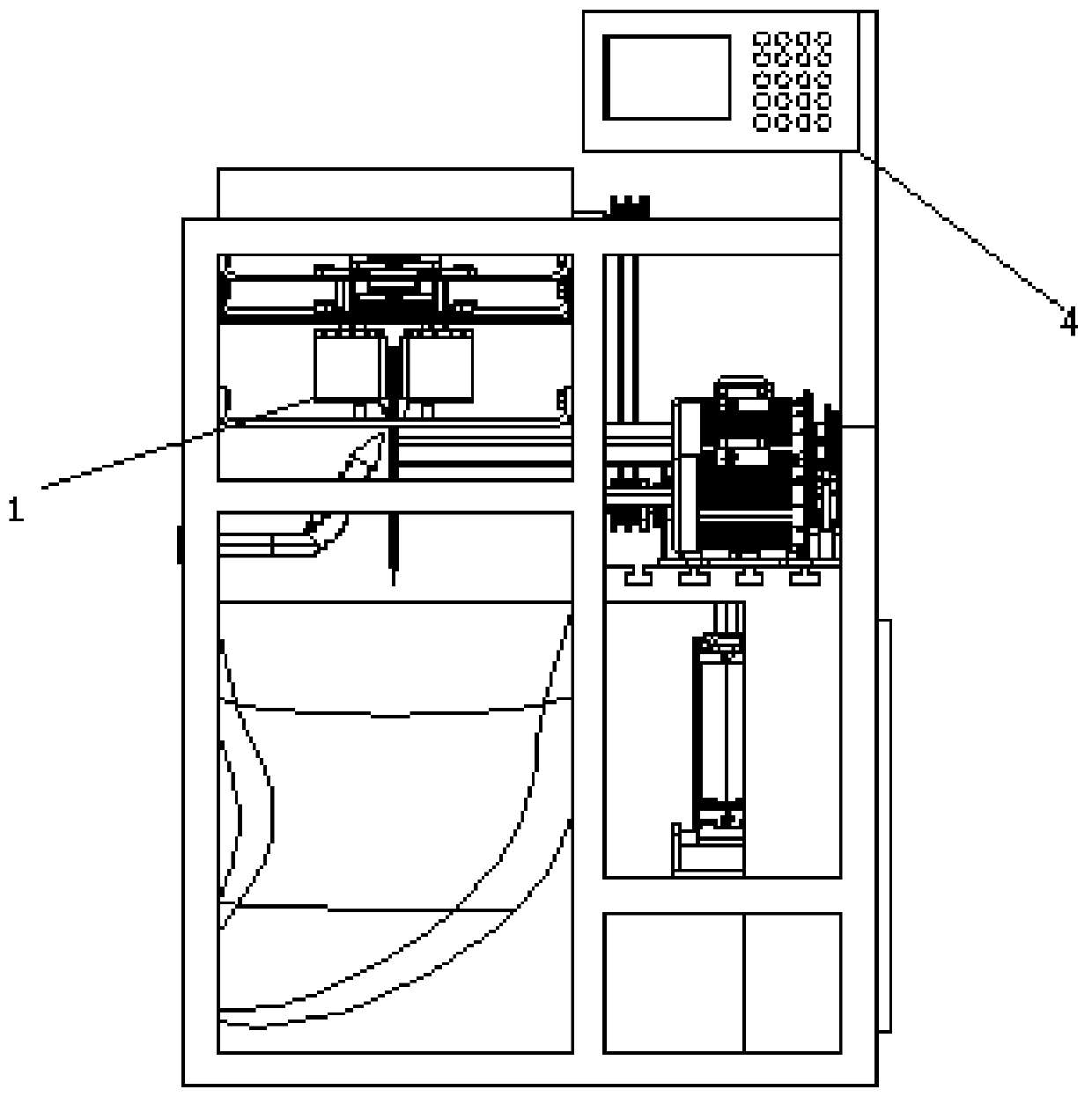

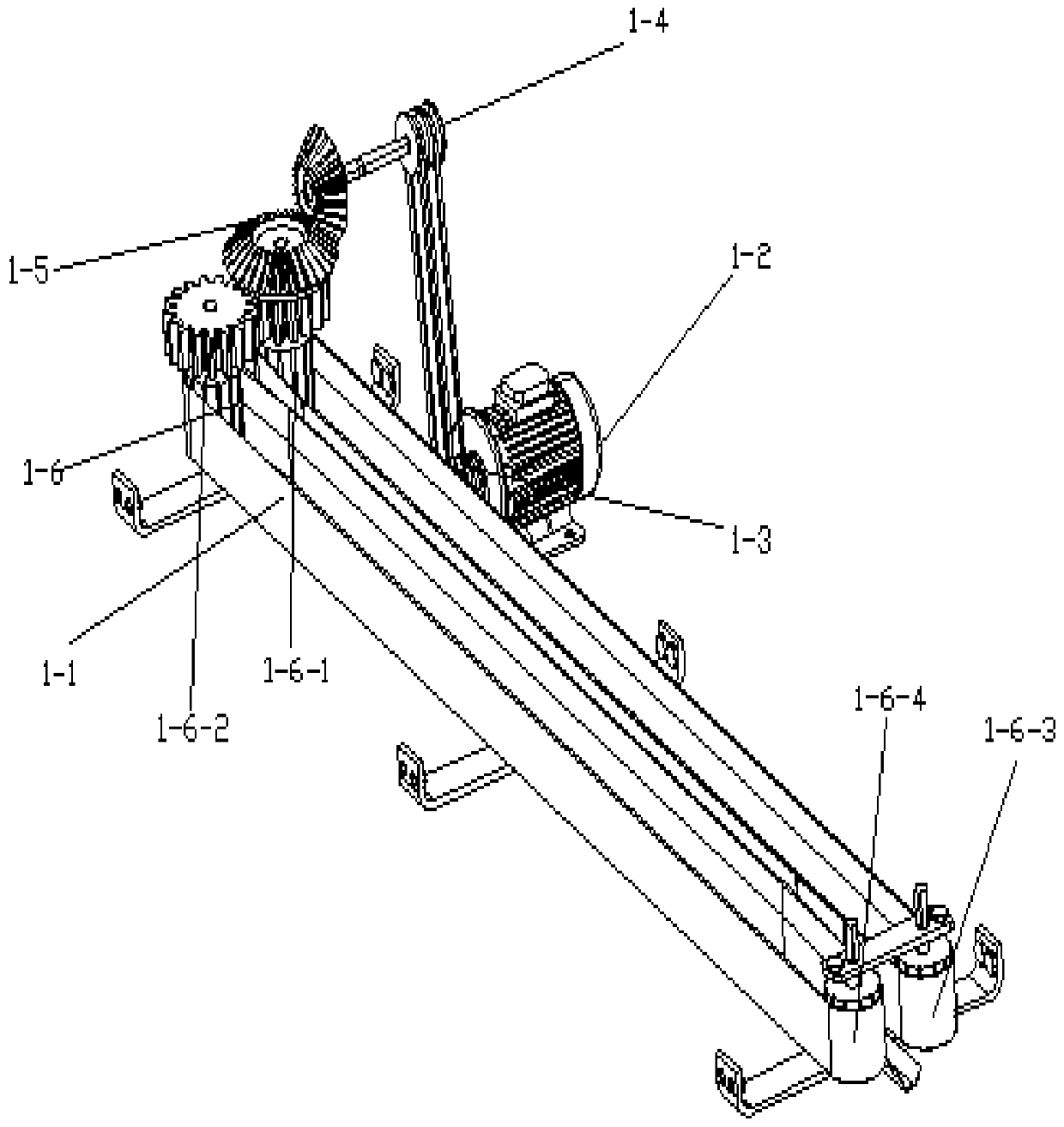

[0050] like figure 1 and figure 2 As shown, a fish visceral cleaning device provided in this embodiment includes a transmission mechanism 1, a visceral mechanism 2, a water spray device 3, a control system 4, a clamping mechanism and a frame. Wherein, the frame is the overall frame of the fish cleaning device for removing dirty parts, and is used for placing the rest of the components. Specifically, in this embodiment, the transmission mechanism 1 is fixed on the groove in the frame by fasteners, and is used to transfer the fish body so that it can advance automatically; the cleaning mechanism 2 is located below the transmission mechanism 1, placed In the groove part of the frame, the motors of the dirt removal mechanism 2 are fixed on the back of the frame, and the knives of the dirt removal mechanism 2 are fixed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com