Milk tea and preparation method thereof

A technology for milk tea and milk products, which is applied to milk preparations, other dairy products, dairy products, etc., can solve the problems of time-consuming, labor-intensive, and unpreservable homemade milk tea, and achieve rich nutrition, satisfying health, and good shelf life stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

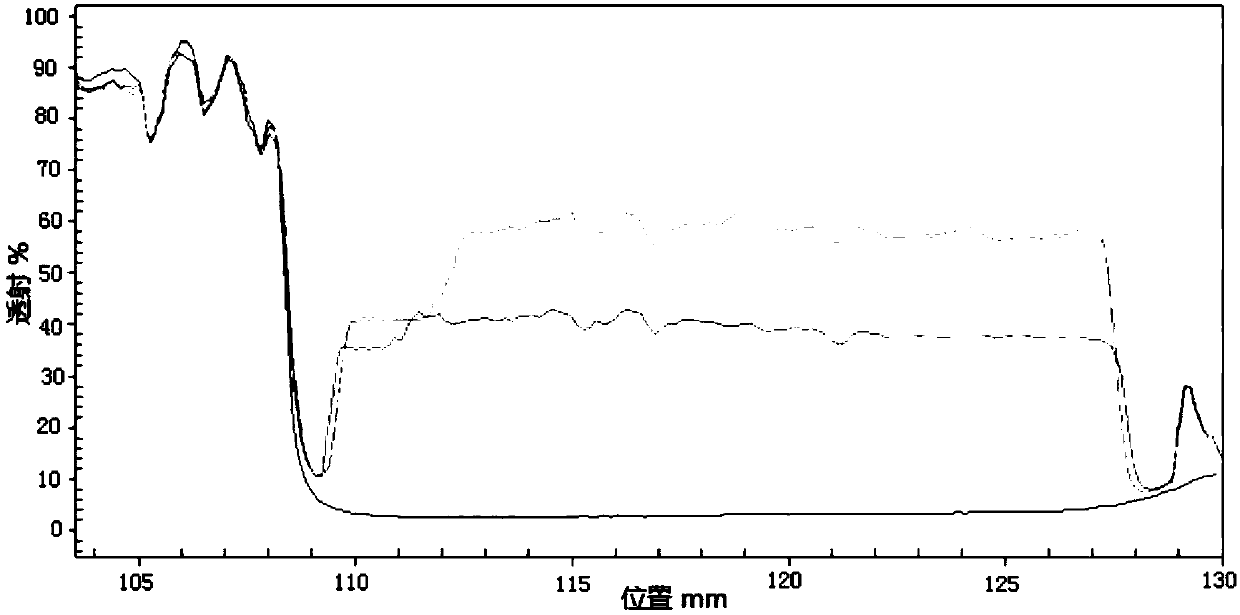

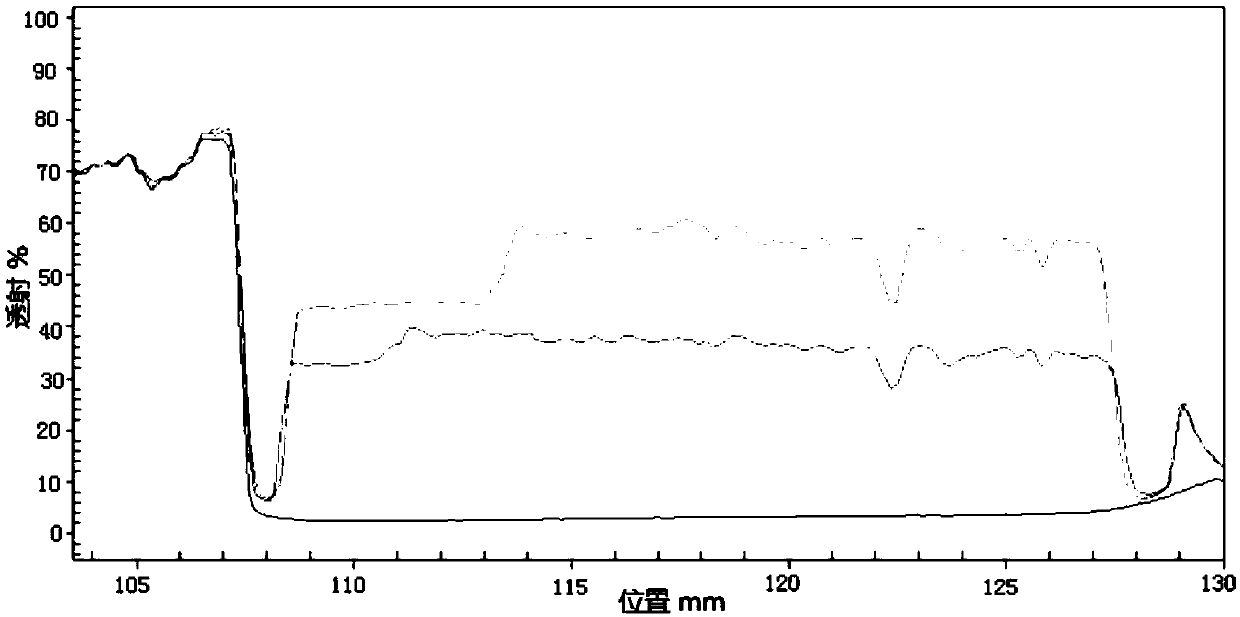

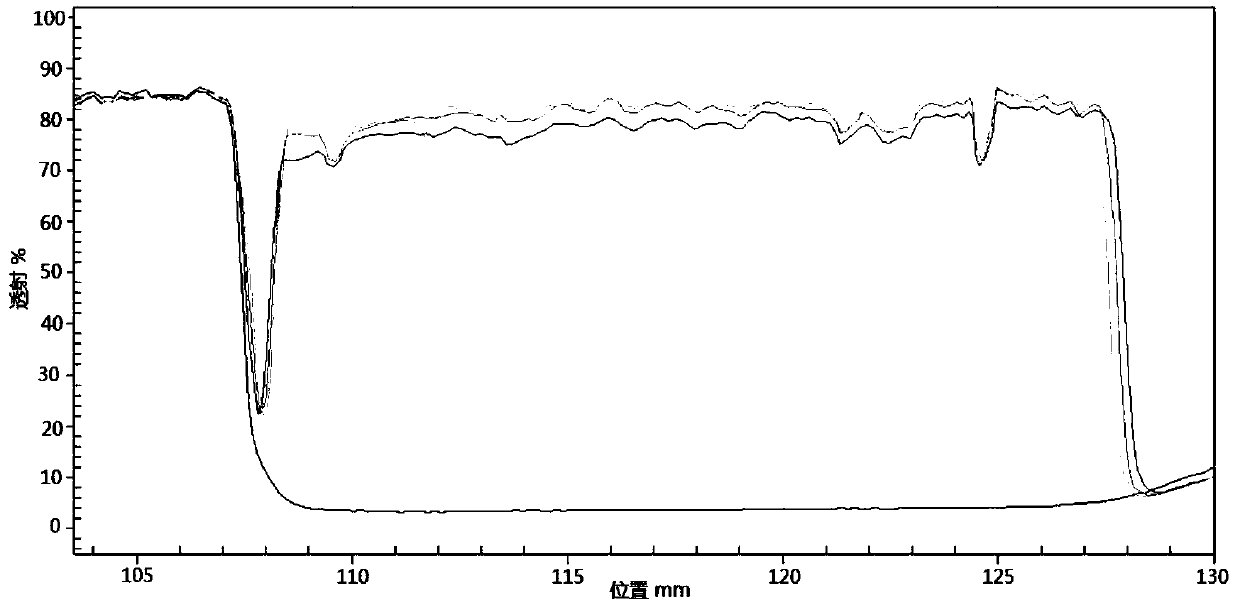

Image

Examples

Embodiment 1

[0027] prepare a milk tea

[0028] 1. Preparation of tea extract:

[0029] Mix tea leaves and drinking water, mix tea leaves and 80°C drinking water at a weight ratio of 1:20, keep a constant temperature of 80°C for intermittent stirring, stir for 2 minutes, stop for 2 minutes, repeat 3 times (stirring speed: 30- 60rpm) brewing for 10min; cool the brewed tea leaves to 10°C, use 80-mesh sieve to filter twice, and the obtained tea filtrate is separated by a separator. The specific separation parameters of the separator are 4500rpm / 400mL. After separation, The liquid is the tea extract.

[0030] Second, the preparation of milk tea:

[0031] 1. Weigh 300 parts by weight of raw milk; 50 parts by weight of white granulated sugar; 650 parts by weight of tea extract, stir and mix at 60°C until uniform.

[0032] 2. Degas the feed solution from step 1) at 65°C.

[0033] 3. The degassed material is homogenized at 65°C, and the homogenization pressure is 30 / 180bar.

[0034] 4. The ho...

Embodiment 2

[0037] prepare a milk tea

[0038] 1. Preparation of tea extract:

[0039] Mix tea leaves and drinking water, mix tea leaves or tea powder or tea concentrate with 80°C drinking water at a weight ratio of 1:25, keep a constant temperature of 80°C for intermittent stirring, stir for 2 minutes, stop for 2 minutes, repeat 3 times Brew for 10 minutes once (stirring speed: 30-60rpm); cool the brewed tea leaves to 10°C, use a 100-mesh screen to filter twice, and separate the obtained tea filtrate with a separator. The specific separation parameters of the separator are: 5000rpm / 400mL, the liquid obtained after separation is the tea extract.

[0040] Second, the preparation of milk tea:

[0041] 1. Weigh 560 parts by weight of raw milk; 40 parts by weight of white granulated sugar; 400 parts by weight of tea extract, stir and mix at 60°C until uniform.

[0042] 2. Raise the temperature of the feed liquid from step 1) to 75°C, enter the steam immersion sterilizer (using Infusion ste...

Embodiment 3

[0048] prepare a milk tea

[0049] 1. Preparation of tea extract:

[0050] Mix tea leaves and drinking water, mix tea leaves or tea powder or tea concentrate with 85°C drinking water at a weight ratio of 1:30, keep a constant temperature for intermittent stirring, stir for 2 minutes, stop for 2 minutes, repeat 3 times ( Stirring speed: 30-60rpm) brewing for 10min; cooling the brewed tea leaves to 10-15°C, using a 120-mesh screen to filter twice, and the obtained tea filtrate is separated by a separator. The specific separation parameters of the separator are 7500rpm / 400mL, the liquid obtained after separation is the tea extract.

[0051] Second, the preparation of milk tea:

[0052] 1. Weigh 670 parts by weight of raw milk; 30 parts by weight of white granulated sugar; 300 parts by weight of tea extract, stir and mix at 60°C until uniform.

[0053] 2. Raise the temperature of the feed liquid from step 1) to 75°C, enter the steam immersion sterilizer (using Infusion sterilizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com