Spiral-wound membrane assembly, composite filter element assembly and water purification system

A composite filter element and rolled membrane technology, applied in the field of water purification, can solve the problems of long flow distance of pure water and large resistance of pure water flow, and achieve the effects of increasing the amount of raw water inflow, increasing the production water flow channel and enhancing the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

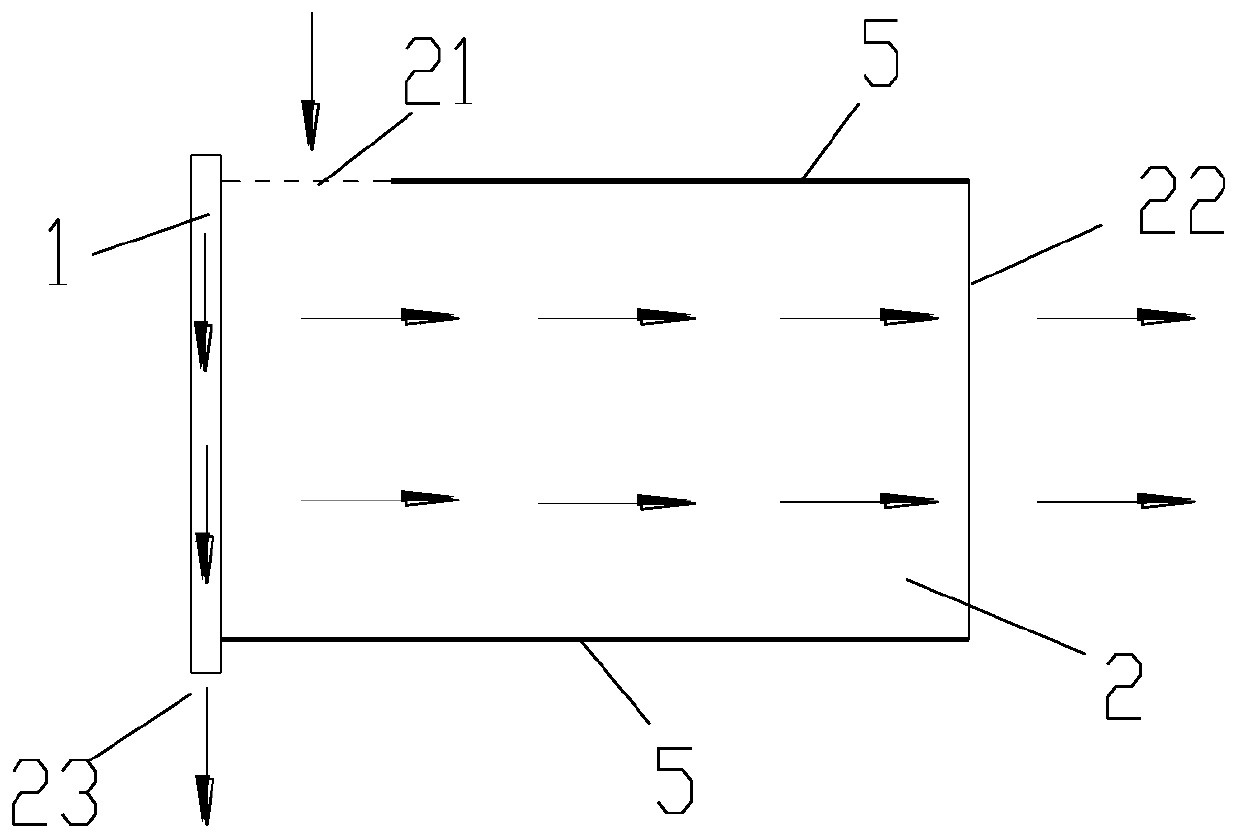

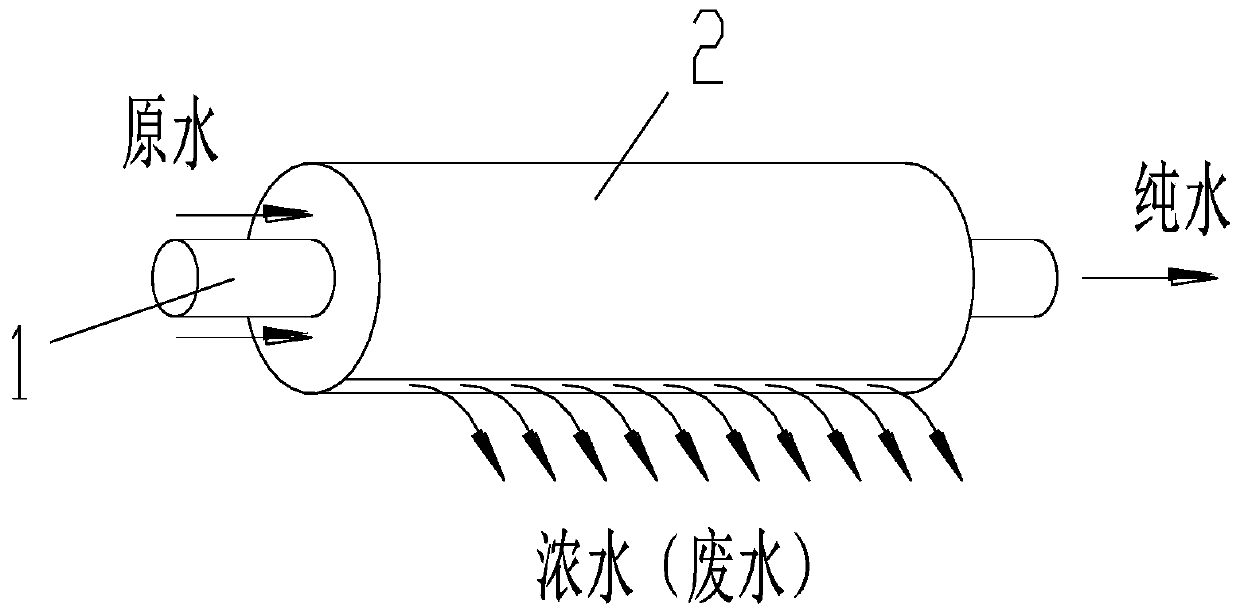

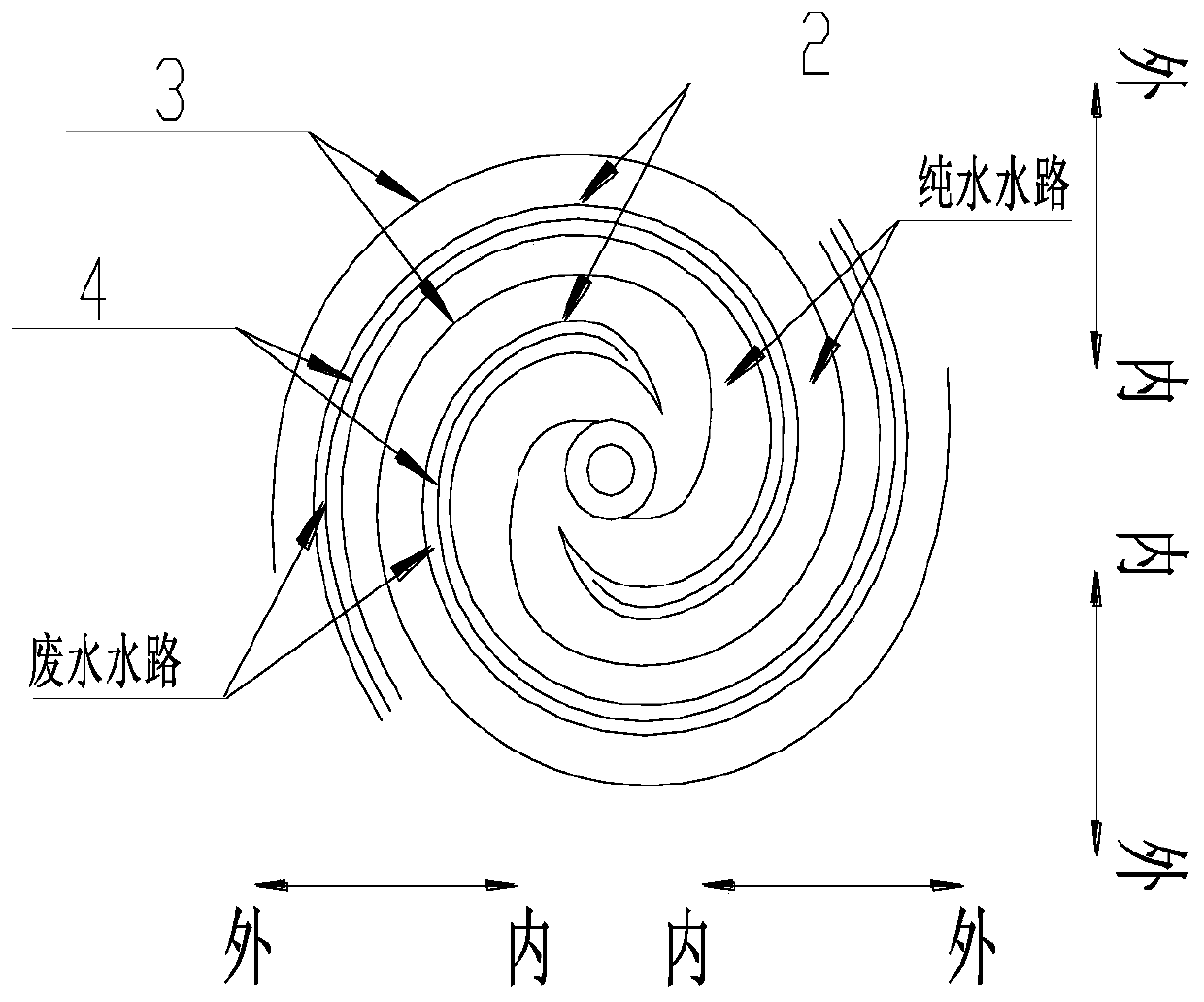

[0040] Such as Figure 1-3 As shown, the present invention provides a roll-type membrane module, which includes:

[0041] The central pipe 1, the central pipe 1 is made of a filter material that allows fluid to pass through, and also includes a rolled membrane 2 that is wound around the outer circumference of the central pipe 1, and the rolled membrane 2 can allow fluid to pass through And to filter the fluid, the coiled membrane 2 is provided with a raw water inlet 21, and the raw water inlet 21 is arranged on one end of the coiled membrane 2 along the axial direction of the central tube 1, and is close to The position of the central tube 1; one end along the axial direction of the central tube 1 on the roll film 2 and the position away from the central tube 1 in the circumferential direction is sealed (closer and farther away are relative relationships, Preferably adopt sealant 5 to seal).

[0042] In the present invention, the raw water inlet is set at the axial end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com