Clean in place (CIP) heat exchange device

A technology of heat exchange device and heat exchanger, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as waste of resources, and achieve the effect of saving consumption and reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

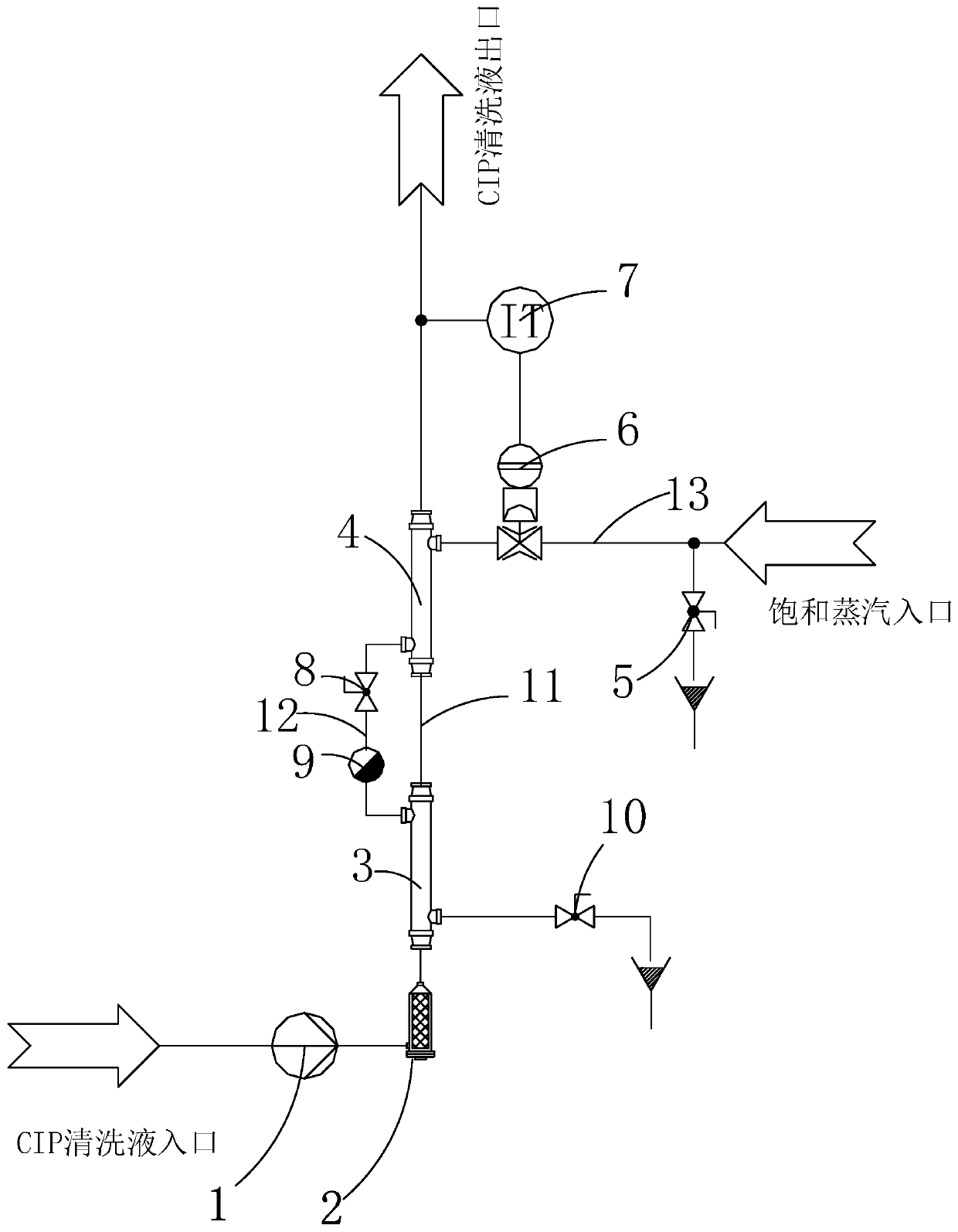

[0017] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] figure 1 A structural block diagram of a CIP heat exchange device provided according to an embodiment of the present invention is shown. Such as figure 1 As shown, the CIP heat exchange device includes a delivery pump 1 , a filter 2 , a condensed water heat exchanger 3 and a steam heat exchanger 4 .

[0020] Wherein, the delivery pump 1 is used to pump the CIP cleaning liquid into the condensed water heat exchanger 3 . The filter 2 is connected between the delivery pump 1 and the conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com