Moving base for machine tool carrying

A technology for moving bases and machine tools, which is applied in the field of machine tools, can solve problems such as machine tool reinforcement, machine tool drop, and machine tool damage, and achieve the effect of avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

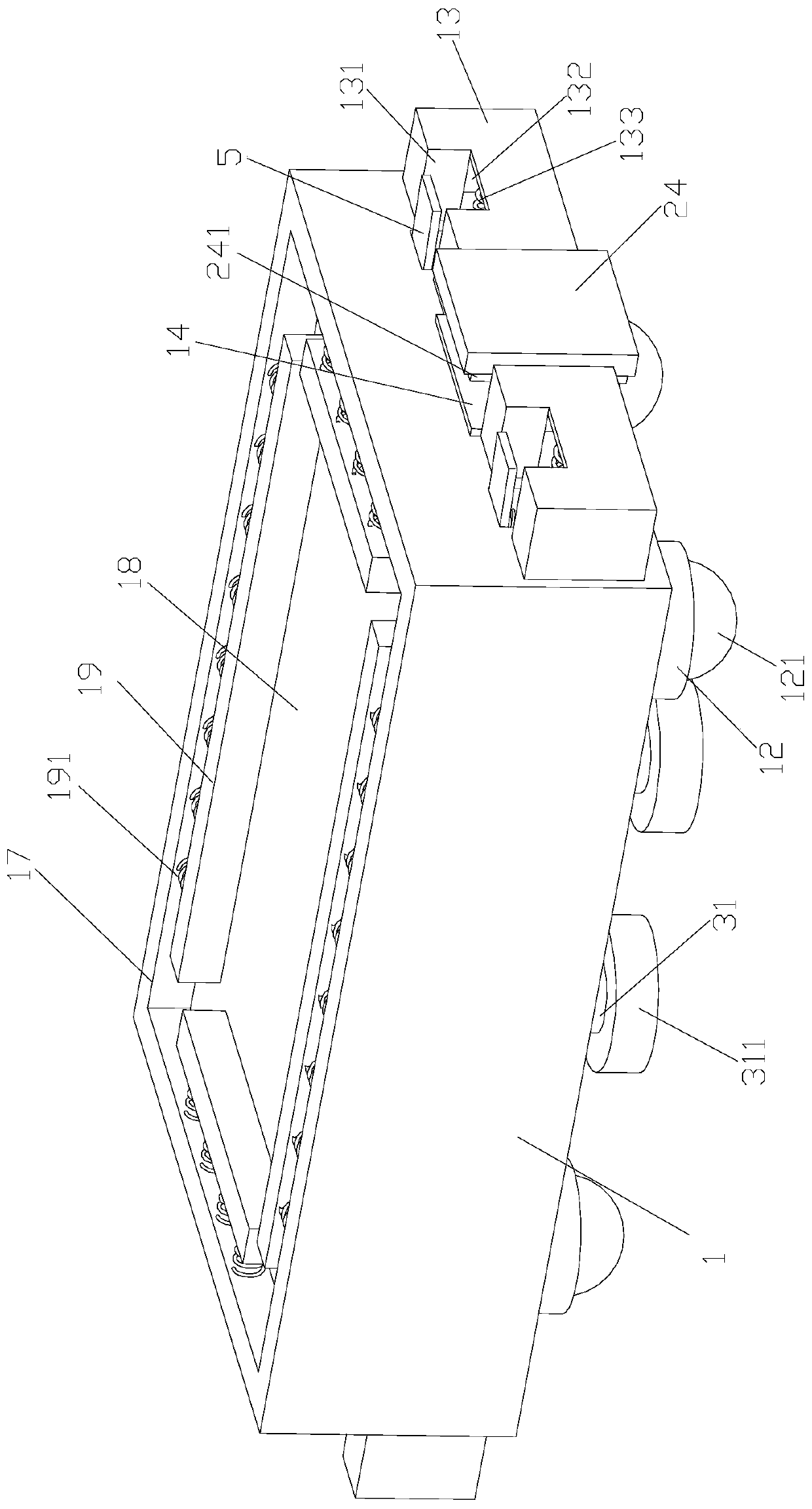

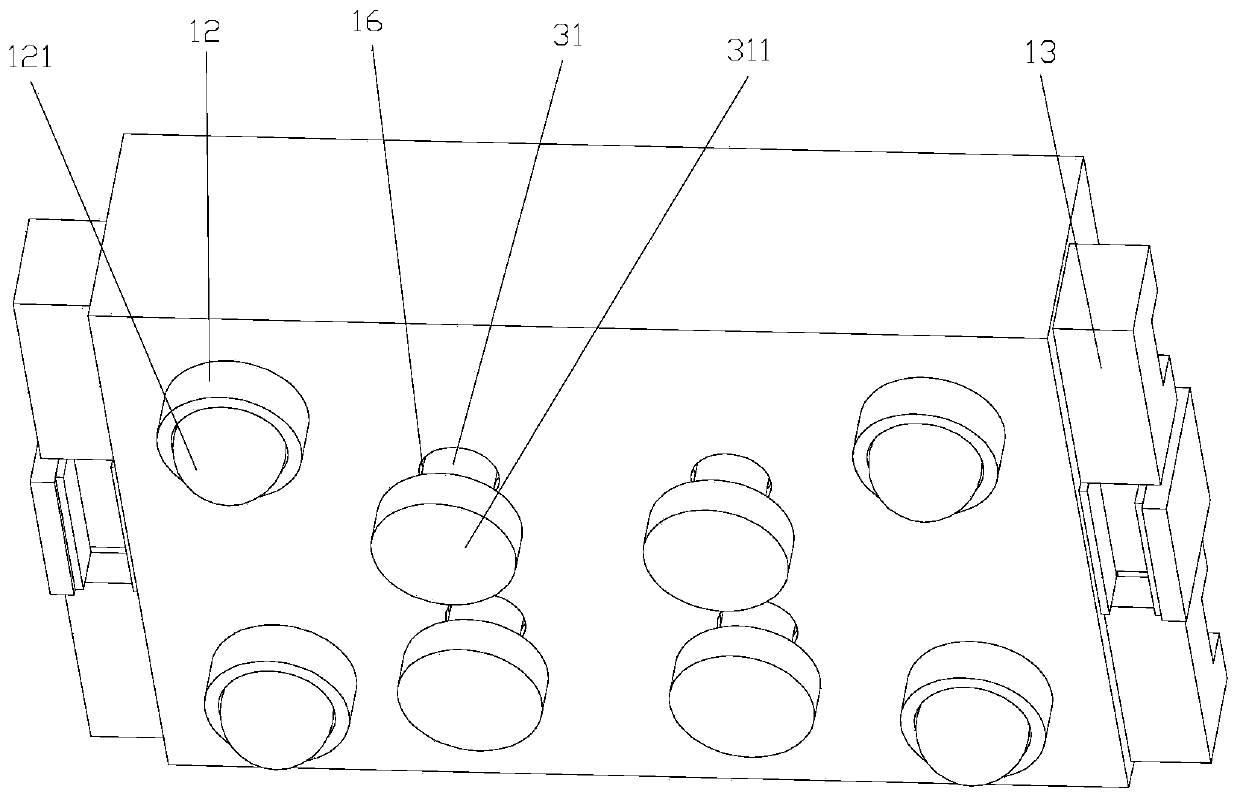

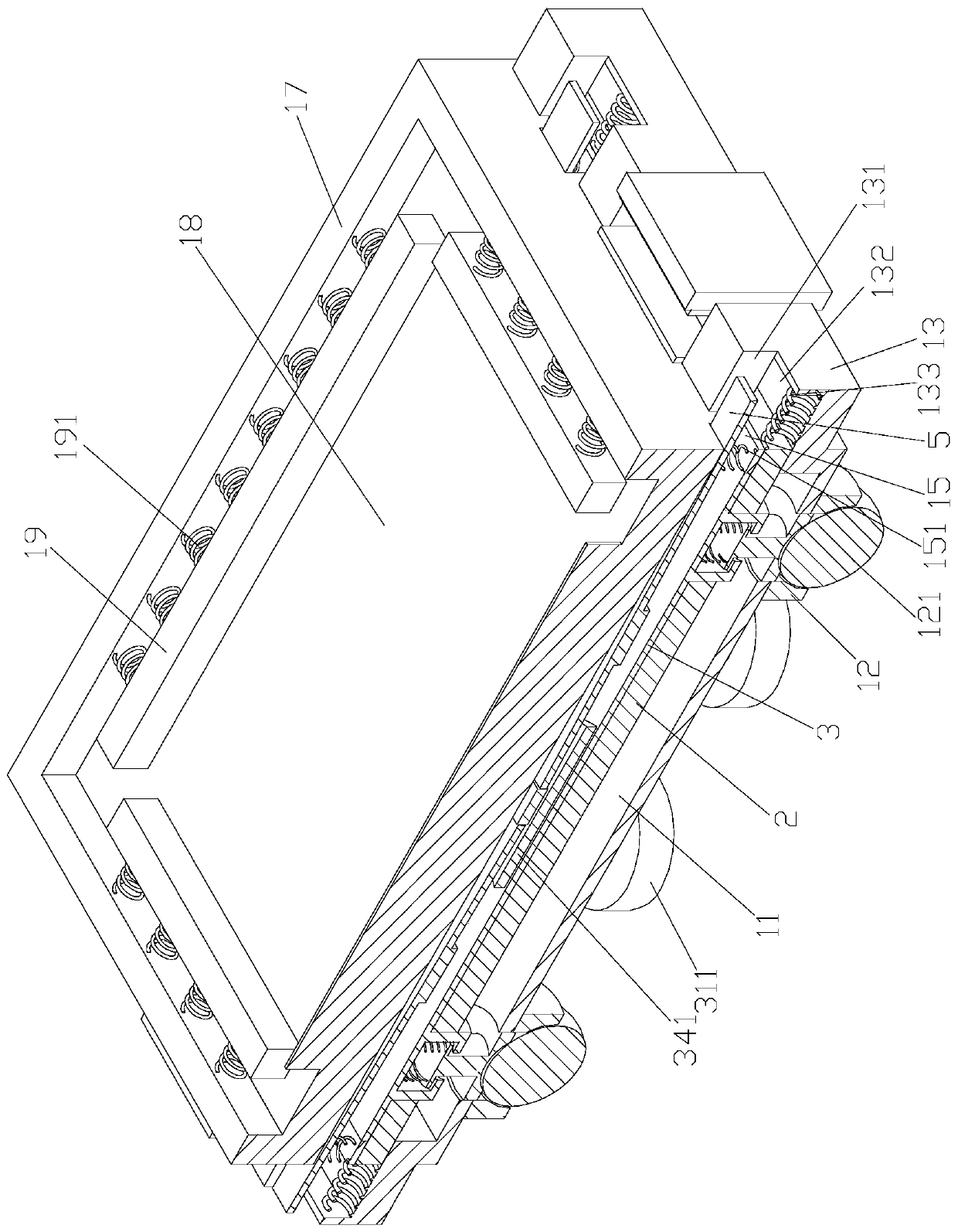

[0019] Such as Figure 1-12 As shown, a mobile base for machine tool transportation includes a support plate 1, a plurality of installation tubes 12 arranged at the bottom of the support plate 1, and rollers 121 arranged in the installation pipes 12, and the rollers 121 are spherical structures , the roller 121 is rotatably connected to the installation pipe 12, the roller cannot escape from the installation pipe, and the spherical structure of the roller enables the roller to realize the function of universal rotation, which is convenient for pushing the base to move in all directions, so that it can be moved according to The machine tool needs to be moved to meet the processing requirements of different machine positions; here, four sets of installation tubes are taken as an example, and the four sets of installation tubes are respectively arranged at the four end points of the bottom of the support plate, and the four sets of installation tubes are arranged symmetrically ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com