High-altitude intelligent operation lamp changing robot

An intelligent operation and robot technology, applied in the field of unmanned aerial vehicles, can solve problems such as the risk of electric shock and strict positioning requirements for lamps, and achieve the effect of solving the problem of high-altitude lamp replacement, reducing the operation risk of workers, and facilitating drive control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below.

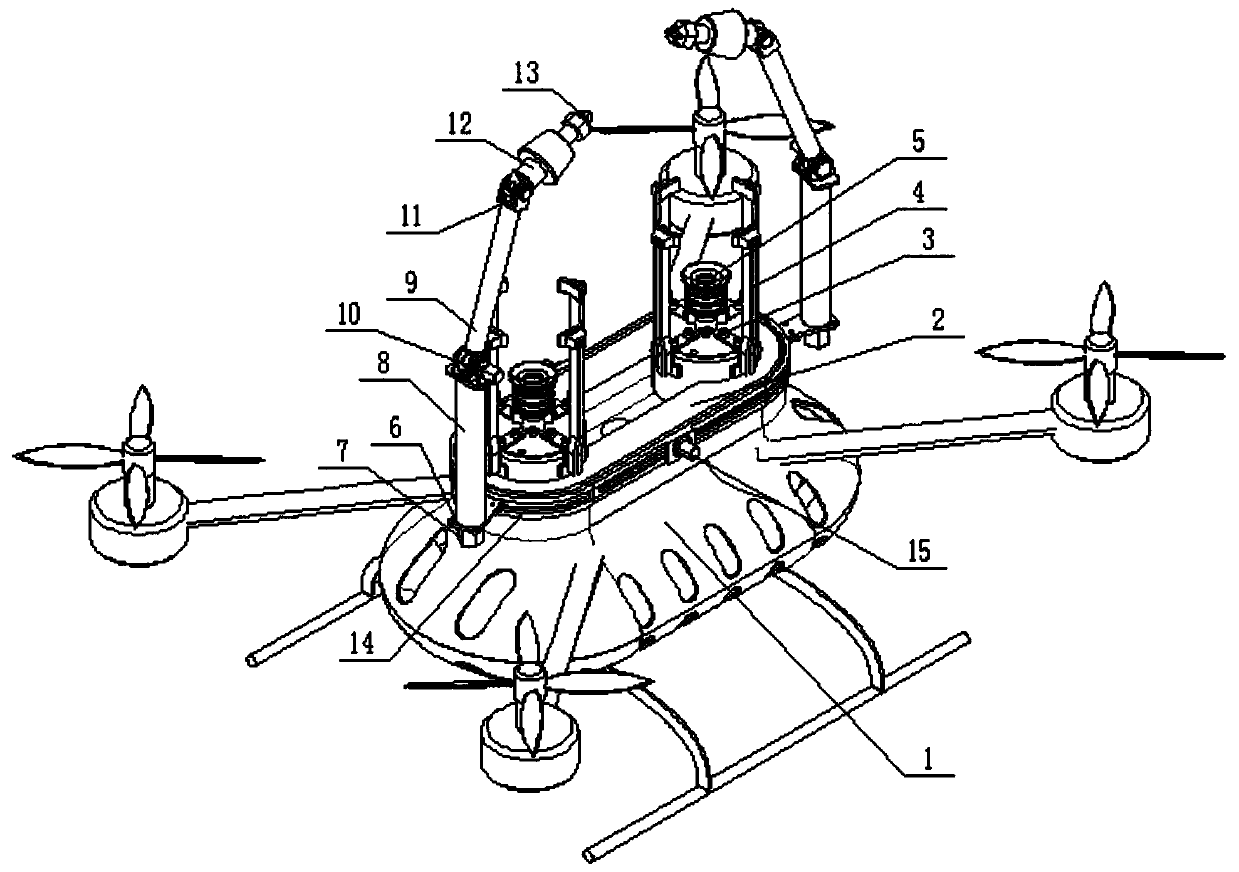

[0022] Such as figure 1 As shown, a high-altitude intelligent operation lamp-changing robot includes an unmanned aerial vehicle 1, an operating platform 2 is arranged above the unmanned aerial vehicle 1, two lamp positioning devices 3 are arranged on both sides of the operating platform 2, and two lamp positioning devices 3 are arranged in the middle. Equipped with a camera, two screw-tightening manipulators that can move around the operating platform 2 are set around the operating platform 2. The camera can specifically identify the position where the lamp is dismantled, and then control the screw-tightening manipulator through the control system to remove or install the screws on the lamp;

[0023] The lamp positioning device 3 of the present invention includes several supporting claws 4, four supporting claws 4 are arranged, and the four supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com