Switching-type driving device for hybrid vehicle

A hybrid vehicle and driving device technology, which is applied to the arrangement of multiple prime movers of power devices, air pressure power devices, and general power devices, and can solve the problem that the engine torque cannot be fully output, fuel economy cannot be exerted, Problems such as transmission efficiency and power loss, to achieve good fuel economy, good fuel economy, and good power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

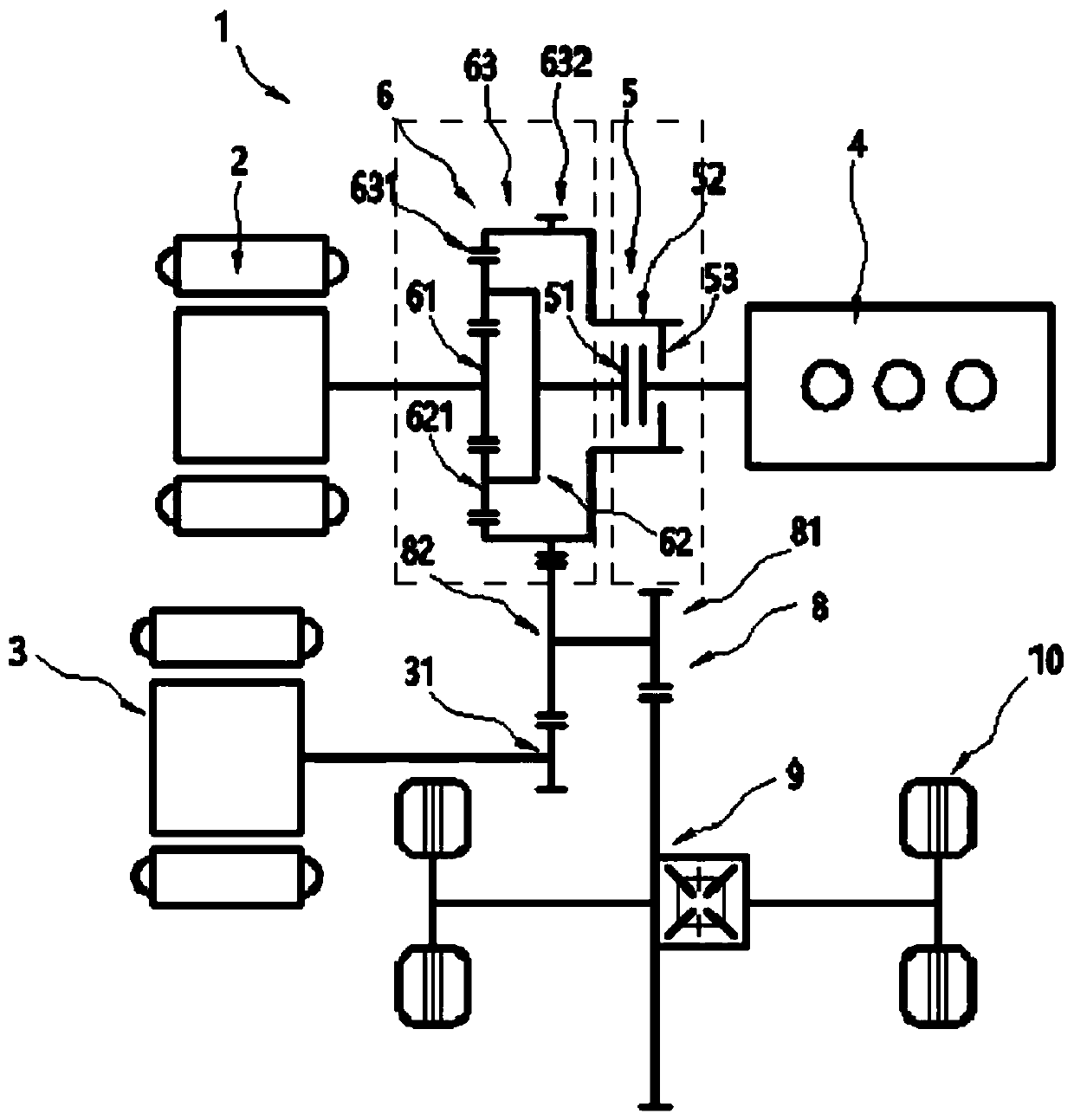

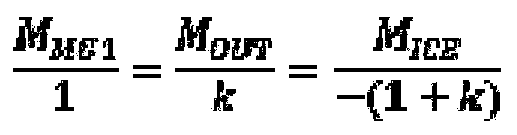

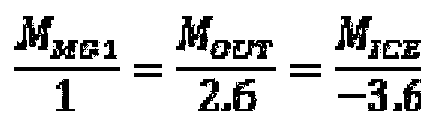

[0026] This embodiment provides a switchable driving device for a hybrid vehicle, including a planetary row 6, a dual-selection connection switching device 5 rotationally connected to the planetary row 6, an engine 4 connected to the input end of the dual-selection connection switching device 5, The external teeth 632 of the ring gear 63 in the planetary row 6 are connected with an intermediate shaft assembly 8, the output end of the intermediate shaft assembly 8 is connected with the input end of the wheel assembly 10, and the double-selection connection switching device 5 includes an active Unit 52, a first passive unit 51 and a second passive unit 53, the active unit 52 is respectively connected to the first passive unit 51 and the second passive unit 53 in a switchable rotational connection; the first passive unit 51 rotates in an integral manner It is coaxially connected with the planet carrier 62 of the planetary row 6, and the second passive unit 53 is coaxially connecte...

Embodiment 2

[0028] This embodiment is further optimized on the basis of Embodiment 1. Specifically, the planetary row 6 also includes a sun gear 61 and a planet carrier 62, the sun gear 61 is placed in the middle of the planet carrier 62, and the planet carrier 62 is provided with a plurality of planetary gears 621 for rotation, the sun gear 61, the plurality of planetary gears 621 and the ring gear 63 are sequentially meshed, the ring gear 63 is internally meshed with a plurality of the planetary gears 621 at the same time, and the sun gear 61 is meshed with the ring gear 62 at the same time. A plurality of the planetary gears 621 are meshed.

Embodiment 3

[0030] This embodiment is further optimized on the basis of Embodiment 2. Specifically, the intermediate shaft assembly 8 includes a driving wheel 81 and a driven wheel 82. The driven wheel 82 is connected to the outer ring gear 63 of the planetary row 6 respectively. The tooth 632 meshes with the motor input gear 31, and the driving wheel 81 is connected to the input end of the wheel assembly 10; the so-called low-speed driving range of the vehicle generally refers to road conditions similar to urban road conditions, where the average vehicle speed is not high, and frequent or occasional short-term parking and waiting. The so-called high-speed driving range of vehicles generally refers to situations similar to high-speed road conditions, where the average speed is relatively high and relatively stable, and there are occasional high-speed overtaking situations.

[0031] In the low-speed driving range, the active unit 52 of the dual-selection connection switching device 5 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com