A high and low temperature all-in-one machine

An all-in-one, high and low temperature technology, used in refrigerators, fluid heaters, household refrigeration devices, etc., can solve the problems of media overflow, discharge out of the circulation system, hidden dangers of media safety, etc., and achieve the effect of preventing mutual channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

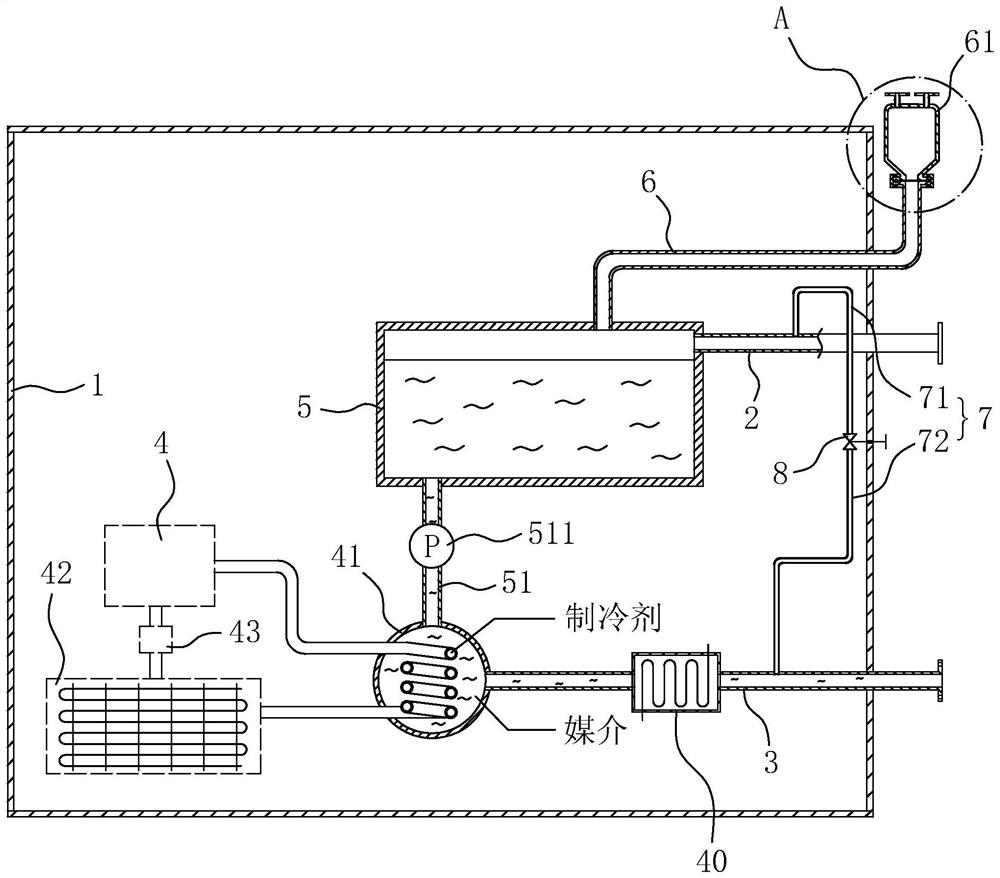

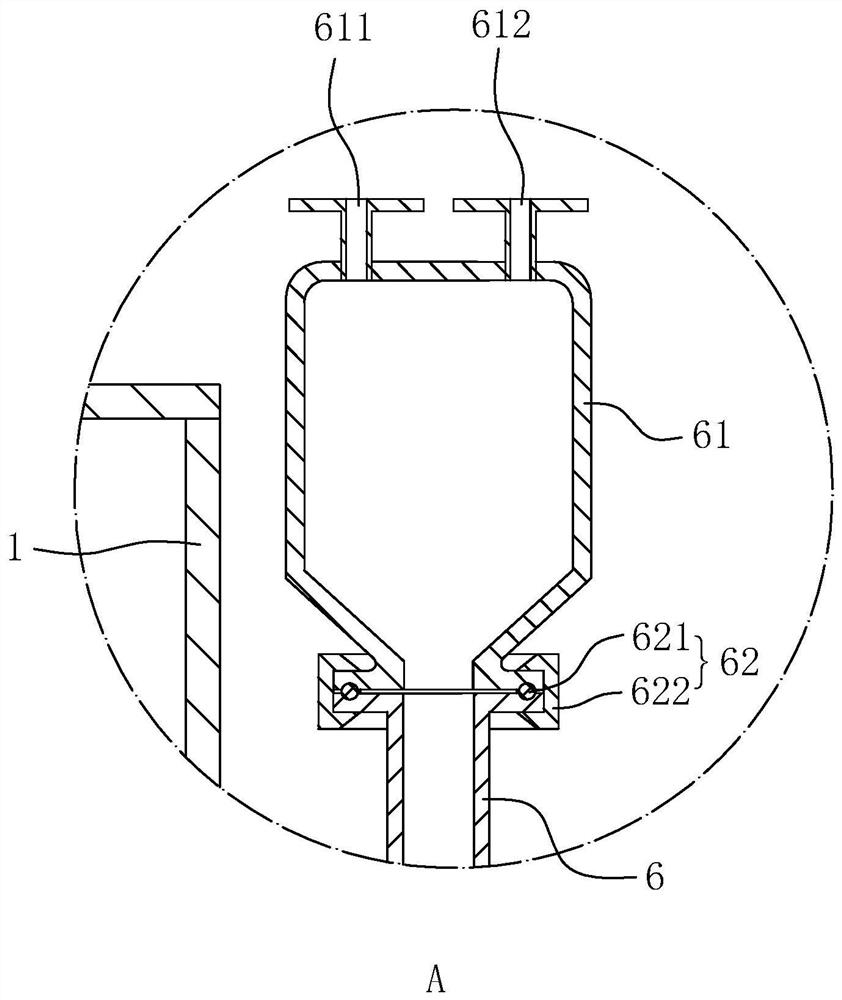

[0037] refer to figure 1 , is a high and low temperature all-in-one machine disclosed by the present invention, comprising a box body 1, which is provided with a medium inlet pipe 2, a medium outlet pipe 3, a compressor 4 for refrigeration, and a heating device 40 for heating , The box body 1 is also provided with a medium box 5 for storing medium, and the medium in this embodiment is heat transfer oil. The compressor 4 is connected with an inner heat exchanger 41 for heat exchange and an outer heat exchanger 42 for heat exchange. The heating device 40 of this embodiment includes a heating box, an electric heating tube arranged in the heating box, and a medium outlet pipe 3 through the heating box. One end of the medium inlet pipe 2 and the medium outlet pipe 3 is located inside the box body 1, and the other end passes out of the box body 1 for communication with subsequent equipment for use of the medium.

[0038]The end of the medium inlet pipe 2 located in the box body 1 ...

Embodiment 2

[0049] A high and low temperature all-in-one machine, the difference between Embodiment 2 and Embodiment 1 is:

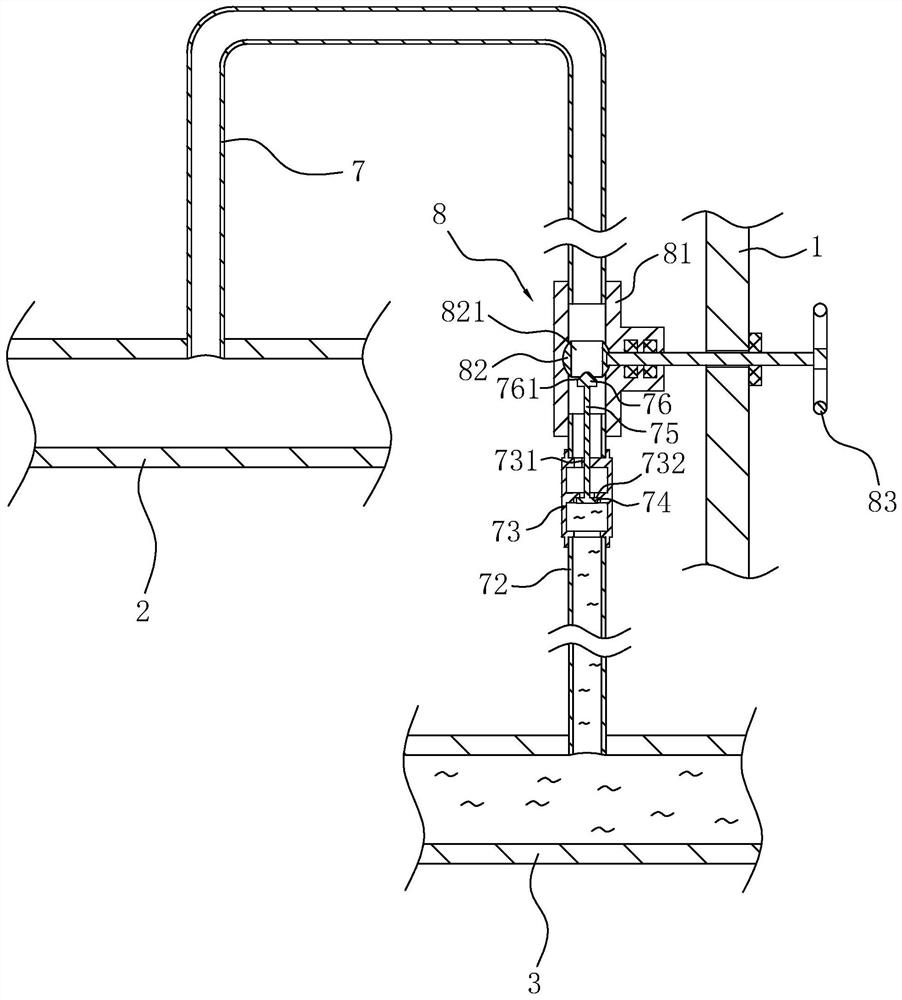

[0050] refer to figure 1 and image 3 The exhaust valve 8 is a ball valve. The exhaust valve 8 includes a valve seat 81, a spherical valve core 82, and a handle 83 located outside the valve seat 81. The handle 83 is used to drive the valve core 82 to rotate. Through the communicating port 821. The valve seat 81 is a straight-through type, the valve seat 81 is fixed on the middle section 72, and the connecting line between the inlet and outlet ends of the valve seat 81 is along the vertical direction.

[0051] The middle section 72 includes a detachable installation section 73 . The installation section 73 is located below the exhaust valve 8 and close to the valve seat 81 . The installation section 73 connects the middle section 72 . The installation section 73 is cylindrical, the two ends of the installation section 73 are screwed to the middle section 72, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com