Release valve and dissolved air water sampling system

A sampling system and release valve technology, applied in the field of dissolved air system, can solve the problems of low bubble density, unfavorable sewage reflux ratio, short bubble residence time, etc., and achieve the effect of high release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

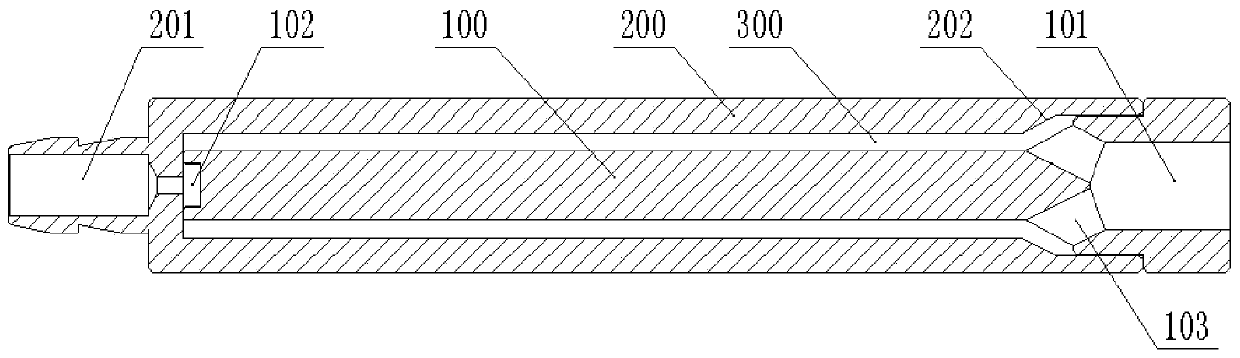

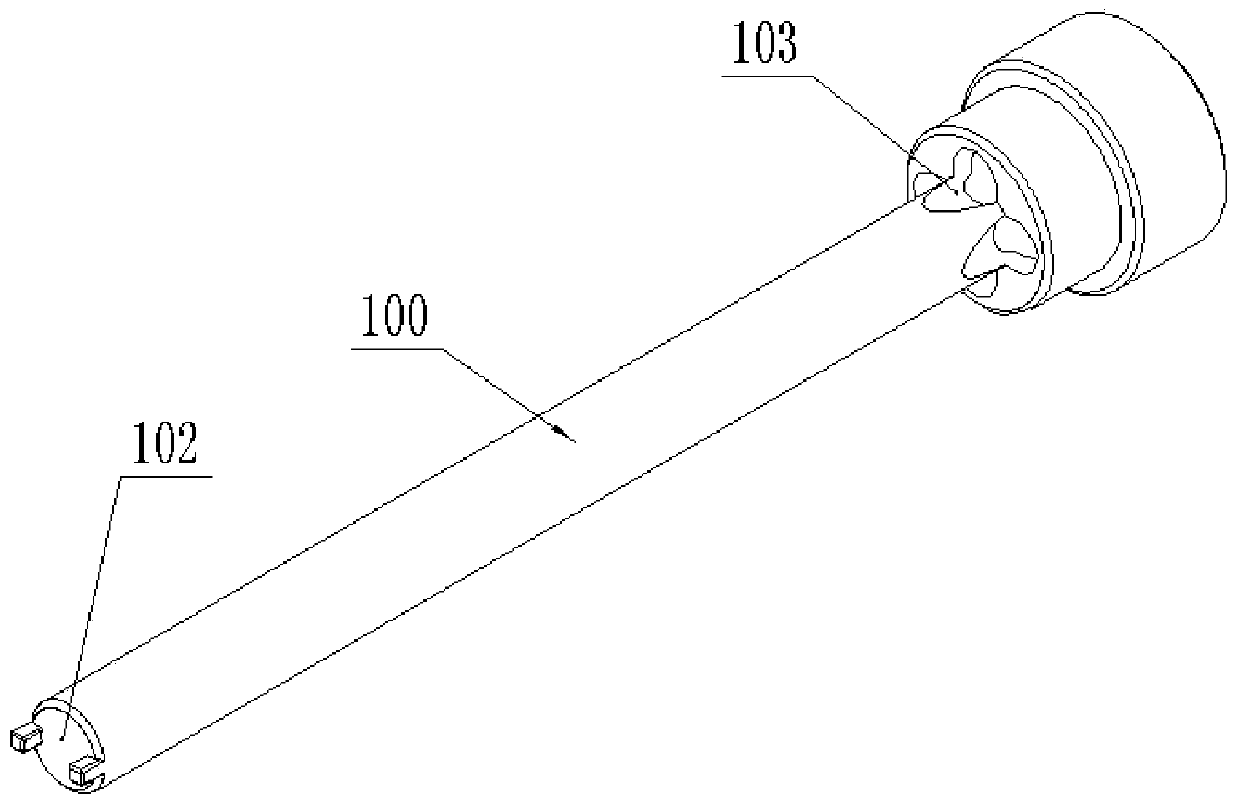

[0028] Such as figure 1 and figure 2 As shown, the release valve provided by the embodiment of the present invention includes: a spout piece 100 and a steady flow sleeve 200 sleeved with the spout piece 100, and a steady flow chamber 300 is formed between the spout piece 100 and the flow sleeve 200; the spout piece 100 is provided with The nozzle 101 and the steady flow sleeve 200 are provided with an inlet 201, and the nozzle 101 and the inlet 201 are in fluid communication with the steady flow chamber 300 respectively; the release valve is configured to disperse the flow from the inlet 201 to the steady flow chamber 300, The liquid flow from the steady flow chamber 300 to the nozzle 101 converges.

[0029] Specifically, the nozzle piece 100 is arranged coaxially with the flow sleeve 200 , and the flow chamber 300 has a circular structure on a section perpendicular to the axis of the flow sleeve 200 , and the spout 101 and the inlet port 201 are coaxial with the flow sleeve...

Embodiment 2

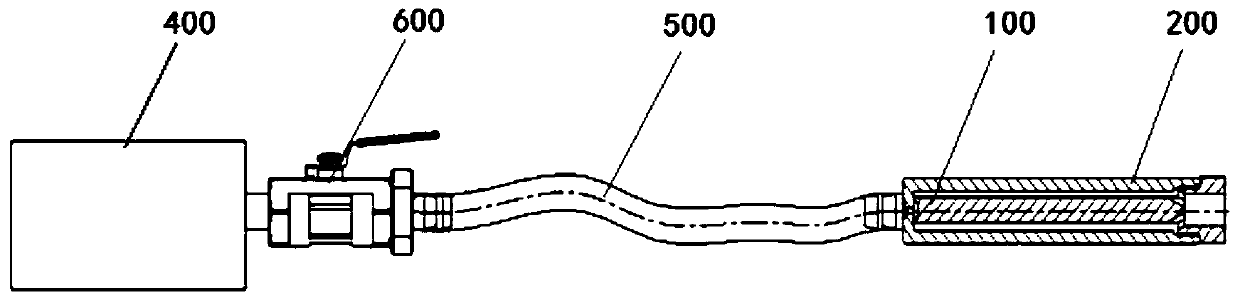

[0045] Such as figure 1 and image 3 As shown, the dissolved air water sampling system provided by the embodiment of the present invention includes: the dissolved air device 400 and the release valve provided in Embodiment 1, and the inlet port 201 is in fluid communication with the dissolved air device 400 .

[0046] Specifically, the air-dissolved water in the air-dissolving device 400 passes into the inlet 201 , and the mechanical energy of the dissolved air water can be reduced by blocking the flow-blocking end face, and the dissolved air water flows into the steady flow chamber 300 from the notch 102 . The air-dissolved water flows along the steady flow chamber 300 , through the steady flow chamber 300 , the dissolved air water has a steady flow effect, and the impact of the dissolved air water is further weakened by the friction of the side wall of the steady flow chamber 300 . The air-dissolved water flows into the spout 101 from the stabilizing flow chamber 300 throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com