Tab inspection and calibration method and device

A calibration method and tab technology, applied in climate sustainability, final product manufacturing, electrolyte battery manufacturing, etc., can solve the problems that the pole pieces and tabs cannot be compensated and adjusted in time, affect the quality of the battery cells, and waste production. Avoid mass scrap, ensure cell quality, and reduce production waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

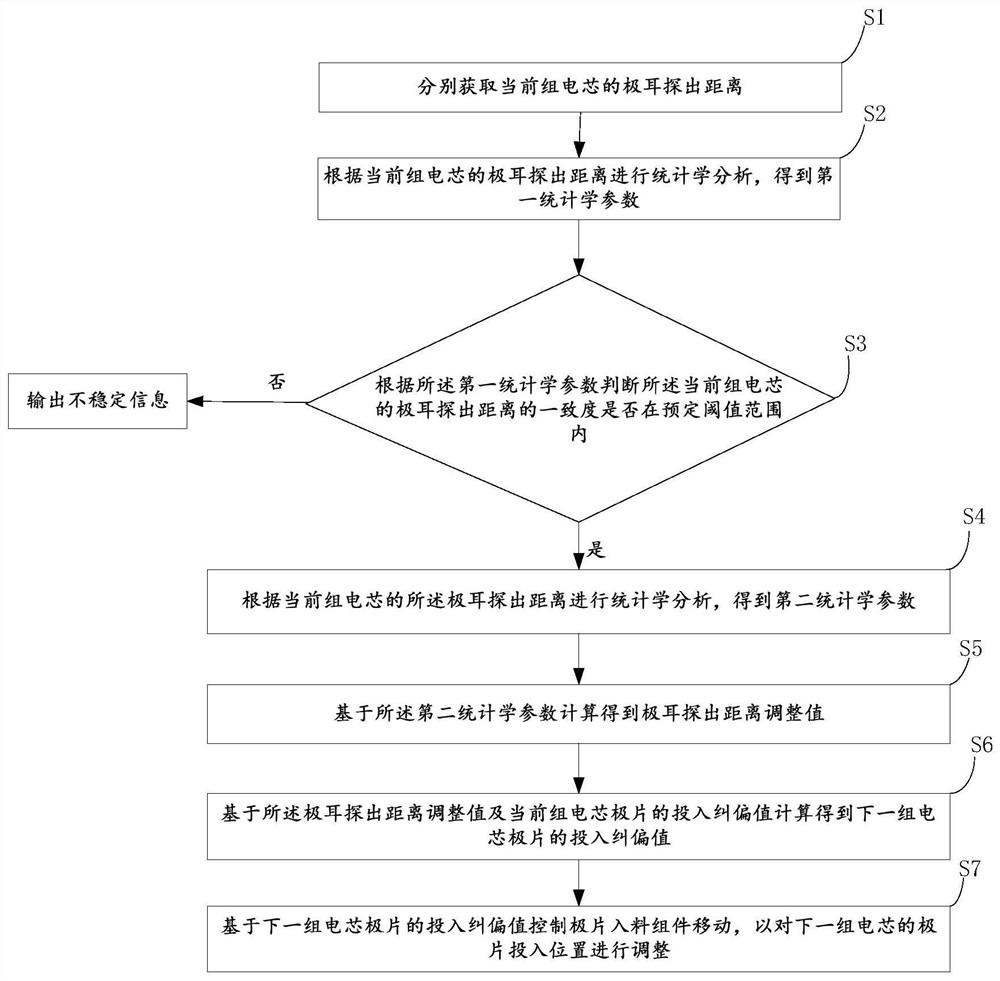

[0065] see Figure 3 to Figure 4 As shown, this embodiment provides a method for checking and correcting tabs, which is applied to electronic equipment, such as controllers. The method includes the following steps:

[0066] Step S1: Obtain the protruding distances of the tabs of the current group of cells respectively, wherein the current group of cells includes at least two cells.

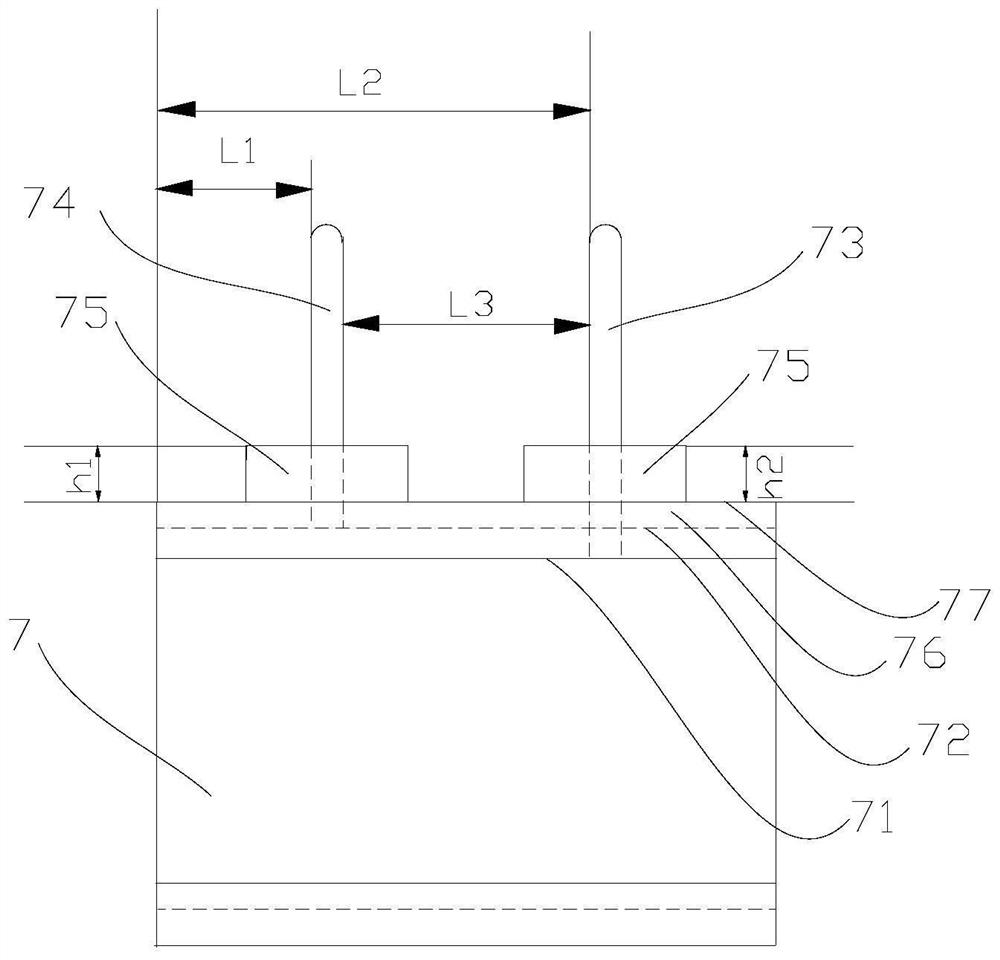

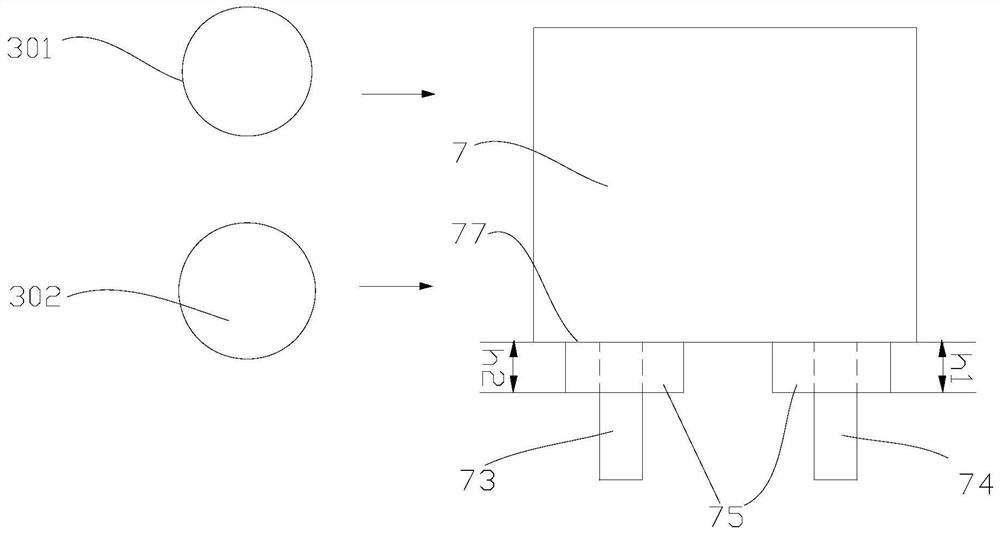

[0067] Wherein, the battery cell generally includes the positive pole tab 73 and the negative pole tab 74, so the tab protruding distance of the battery cell should include the protruding distance h2 of the positive pole tab and the protruding distance h1 of the negative pole tab. The current group of batteries includes at least two cells, and the correspondingly obtained positive tab protruding distance h2 and negative tab protruding distance h1 are at least two respectively. The protruding distance of the tabs of the current group of batteries can be obtained sequentially according to the order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com