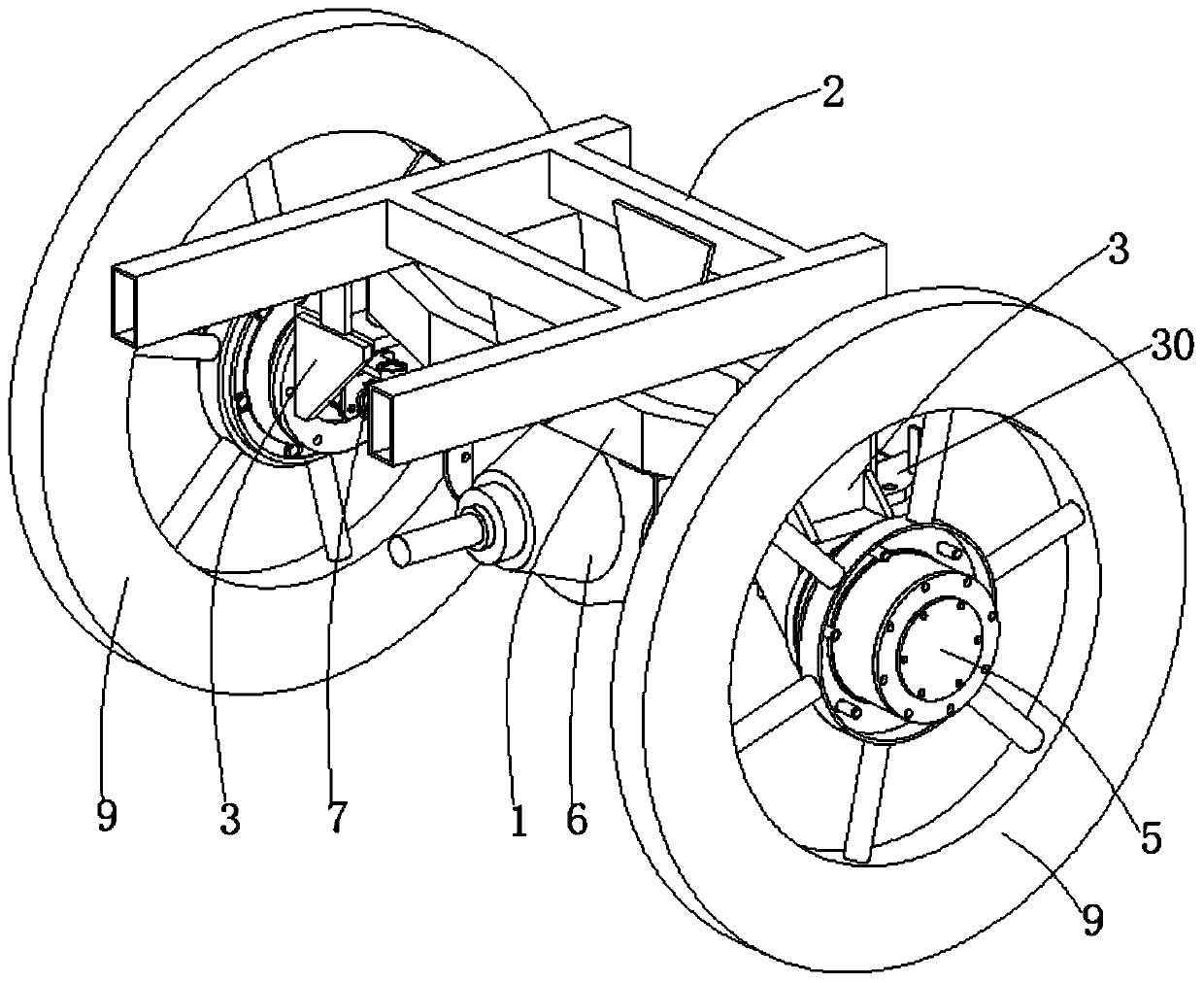

Floating device of paddy field operation equipment driving system

A technology of operation equipment and drive system, applied in agriculture, the chassis of agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of deviation, low ground clearance, low power, etc., to avoid slippage and deviation, and to turn flexibly , the effect of increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

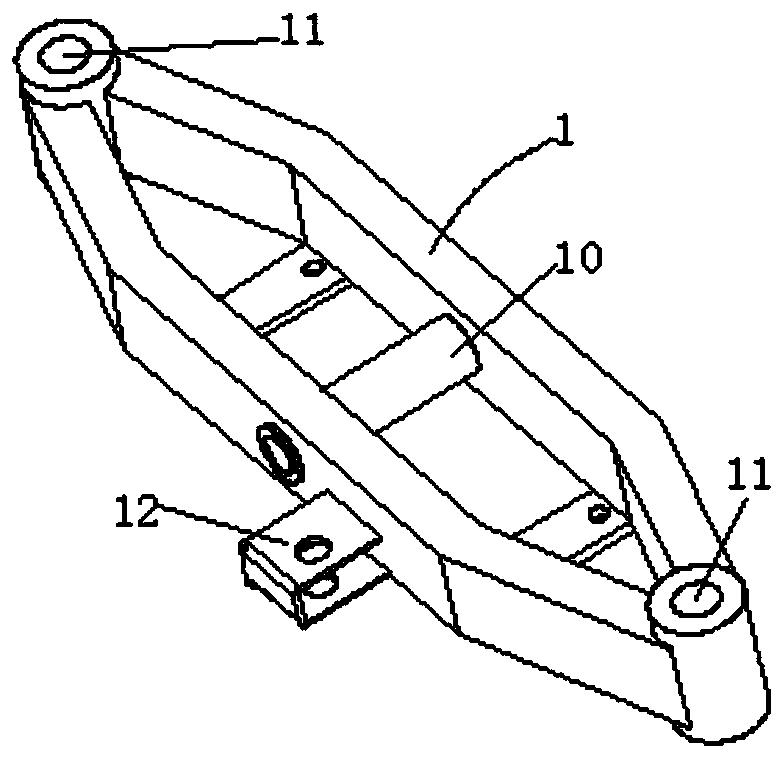

[0039] The floating device of the driving system of the paddy field operation equipment, the torque entered from the input shaft of the differential 6 passes through the differential 6 and then output from the output shaft of the differential 6, and then drives the active fork 1 70 to rotate, and the active fork 1 70 passes through the cross shaft Drive driven fork 1 71-1 rotates with external spline shaft 1 71, external spline shaft 1 71 drives internal spline shaft 1 72 to rotate, and internal spline shaft 1 72 rotates with driven fork 2 72-1, The driven fork two 72-1 drives the driven fork three 73 to rotate through the cross shaft.

[0040] Then the driven fork three 73 drives the universal joint connector 51 to rotate, and the inner spline one 51-1 of the universal joint connector 51 drives the main shaft 53 to rotate through the outer spline two 53-1, and the main shaft 53 is in the needle bearing 5 -2 internal rotation, the external spline three 53-2 at the end of the m...

Embodiment 2

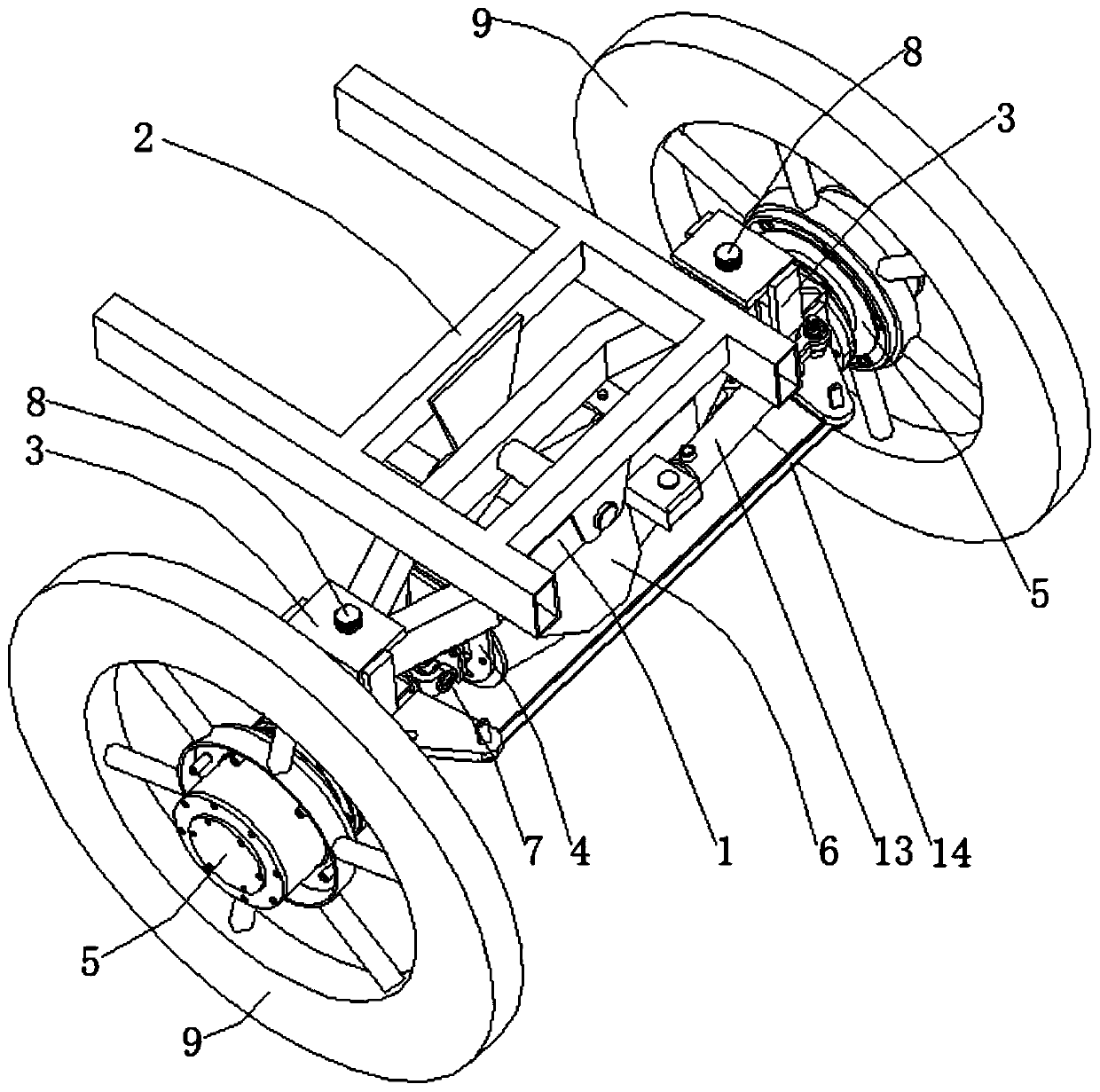

[0042] On the basis of Embodiment 1, the side of the lower frame 1 is provided with a hinged seat 12, and the hinged seat 12 is hinged with a steering cylinder 13, such as Figure 5 As shown, the side wall of the wheel frame 3 is provided with a steering arm 31, the steering arm 31 is provided with an inner pin hole 31-1 and an outer pin hole 31-2, and the end of the piston rod of the steering cylinder 13 and the inner pin hole on one side 31-1 is hinged, and a steering tie rod 14 is arranged between the two outer pin holes 31-2, and a steering arm 31 is driven by the telescoping of the piston rod of the steering cylinder 13 to rotate the wheel frame 3, and the steering tie rod 14 synchronously drives the other A wheel frame 3 rotates to realize the steering operation, and the steering is stable and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com