Vehicle cab assembly fixing point automatic detection device and method

An automatic detection device and fixed detection technology, applied in the fields of motor vehicles, transportation and packaging, sorting, etc., can solve the problems of batch size, unfavorable production cost production efficiency, time-consuming and labor-intensive, etc., to save energy and material resources, and avoid repairs. difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

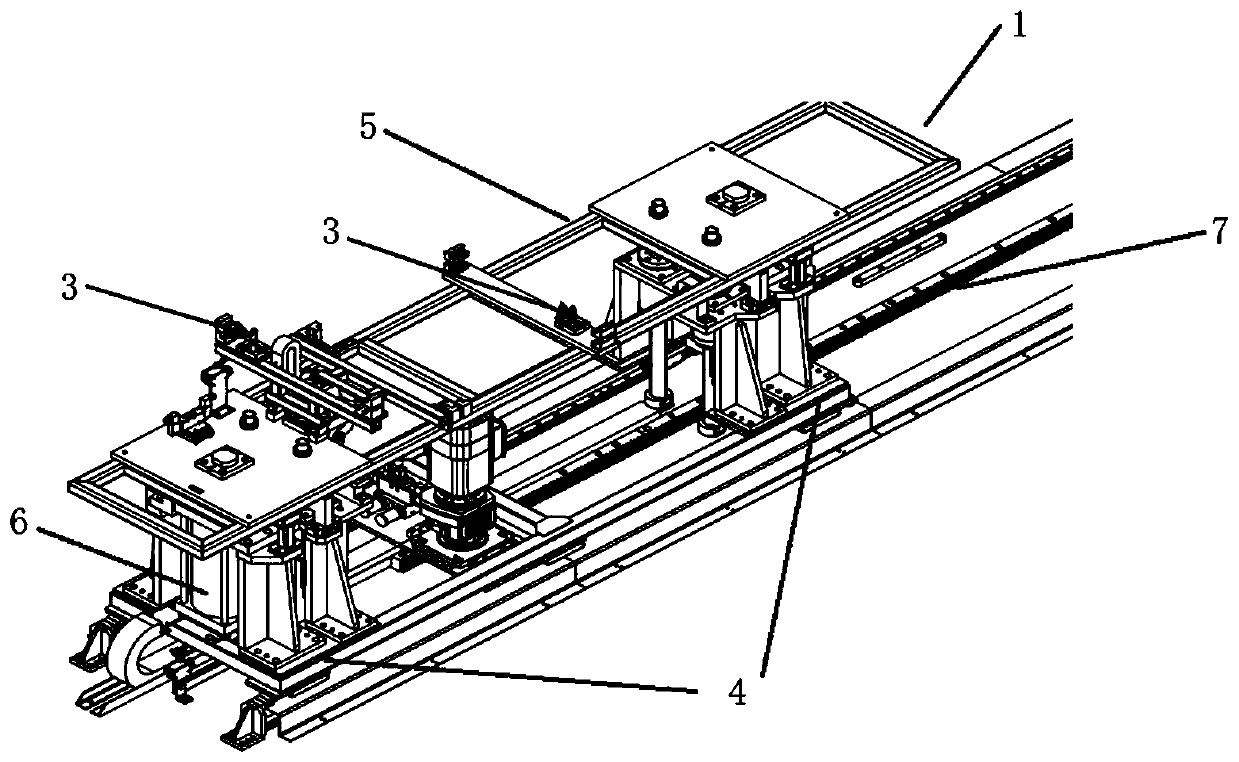

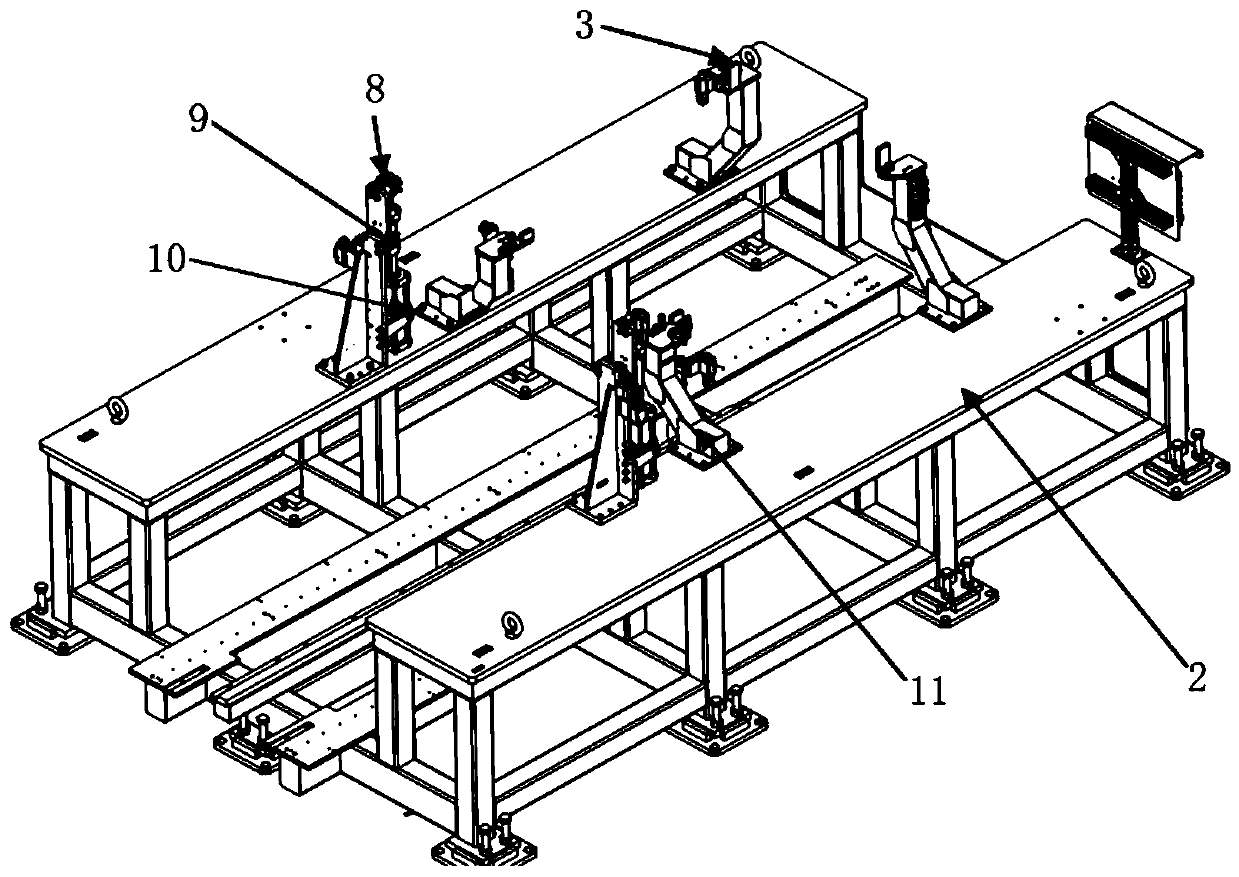

Embodiment 1

[0027] In one or more embodiments, a vehicle cab fixed point automatic detection device is disclosed, including: a movable station 1 realized by a reciprocating rod, and fixed stations symmetrically arranged on both sides of the movable station 1 The base 2; the set positions of the base and the movable station 1 are respectively equipped with detection holes matching the fixed points of the vehicle cab; there are six detection holes, four of which are fixed detection holes 3, and the other two are Retractable detection hole 8.

[0028] The position and size of the detection hole are compatible with the mounting bolts at the fixed point of the vehicle cab, because the cab assembly is assembled step by step, and there are accumulated errors, and when the cab assembly is connected to the frame, it is mainly used The most important thing is the six mounting bolts under the cab assembly; therefore, whether the bolts meet the requirements is detected through the detection holes, so...

Embodiment 2

[0042] In one or more embodiments, a method for automatic detection of fixed points in a vehicle cab is disclosed, including:

[0043] Adjust the retractable detection hole 8 to be in a contracted state;

[0044] Place the vehicle cab assembly at the set position of the movable station 1, and judge whether the detection hole and the first four mounting bolts on the vehicle cab assembly can be completely aligned and matched;

[0045] If it cannot be completely aligned and matched, it is judged that the vehicle cab assembly is unqualified;

[0046] Otherwise, adjust the telescopic detection hole 8 to be in the extended state, and judge whether the telescopic detection hole 8 can be completely aligned and matched with the remaining two mounting bolts on the vehicle cab assembly. The cabin assembly is unqualified; otherwise, the vehicle cab assembly is judged to be qualified.

[0047]After the inspection of the vehicle cab assembly is completed, the vehicle cab assembly is jacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com