Construction method and structure of foundation cushion under condition of current-formed silt soil

A construction method and cushion technology, applied in the direction of basic structure engineering, construction, etc., can solve problems such as construction difficulties, achieve the effects of ensuring construction quality, strengthening overall strength, and preventing soil collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

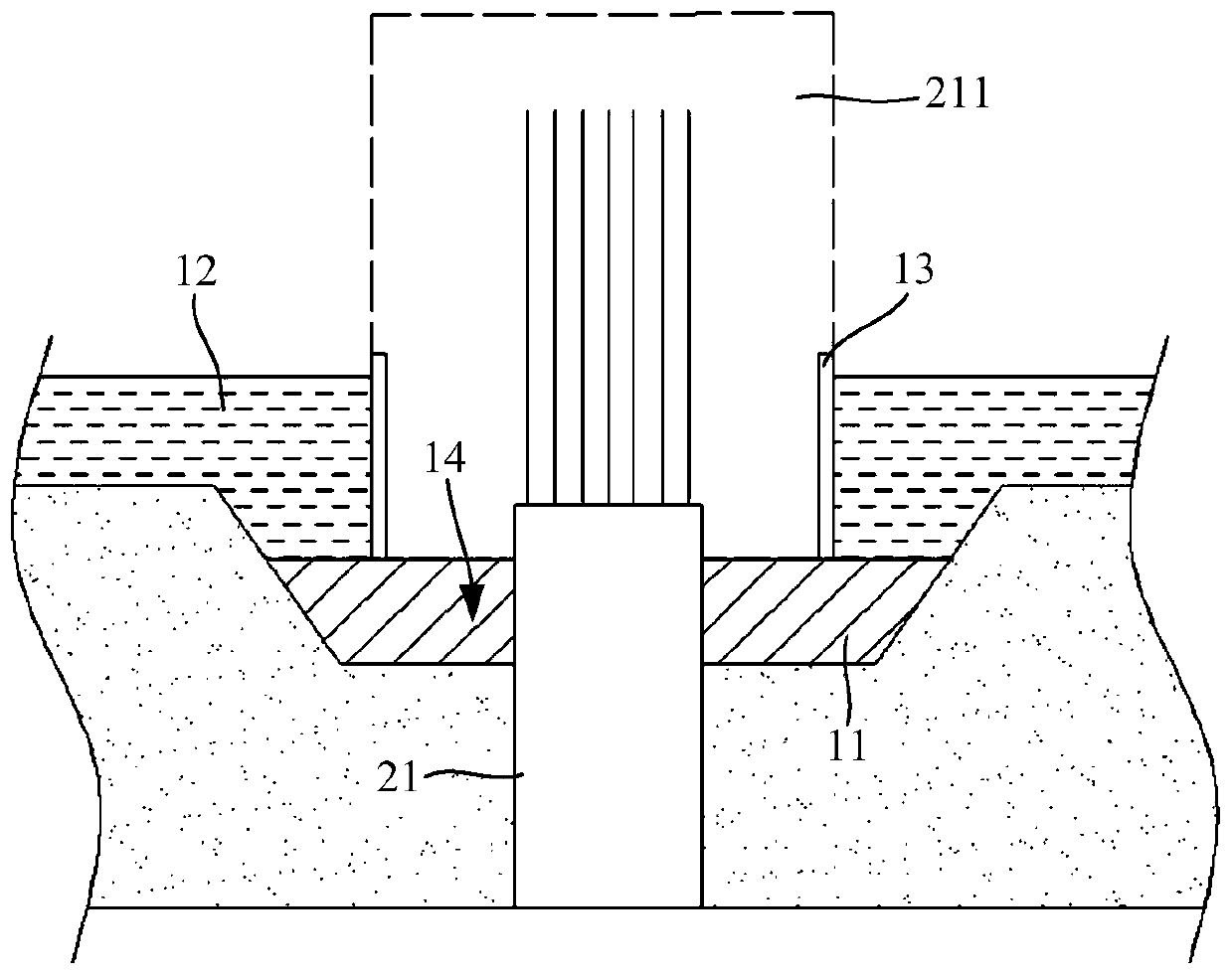

[0050] Set pile foundation 21 at the position to be constructed, excavate the soil body around pile foundation 21 to form foundation pit 14, and pile foundation 21 part exposes this foundation pit 14;

[0051] Concrete is poured at the bottom of the foundation pit 14 to form the cap cushion 11. After the cap cushion 11 reaches the set strength, the position of the cap 211 to be constructed is determined on the cap cushion 11, and the cap 211 is placed on the cap to be constructed. The formwork 13 is supported at the edge of the platform 211;

[0052] Concrete is poured on the platform cushion 11 outside the formwork 13 and the ground outside the foundation pit 14 to form the floor cushion 12, and the template 13 is removed after the floor cushion 12 reaches the set strength;

[0053] Construction floor and cap 211;

[0054] That is, pouring the cap cushion 11 and the bottom plate cushion 12 first, and then constructing the bottom plate and the cap 211 can greatly shorten the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com