Improved preventive maintenance and mean value control chart combined economic optimization method

A technology of economic optimization and control chart, applied in the field of system optimization, can solve problems such as low hazard rate systems, achieve good economic performance and reduce overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

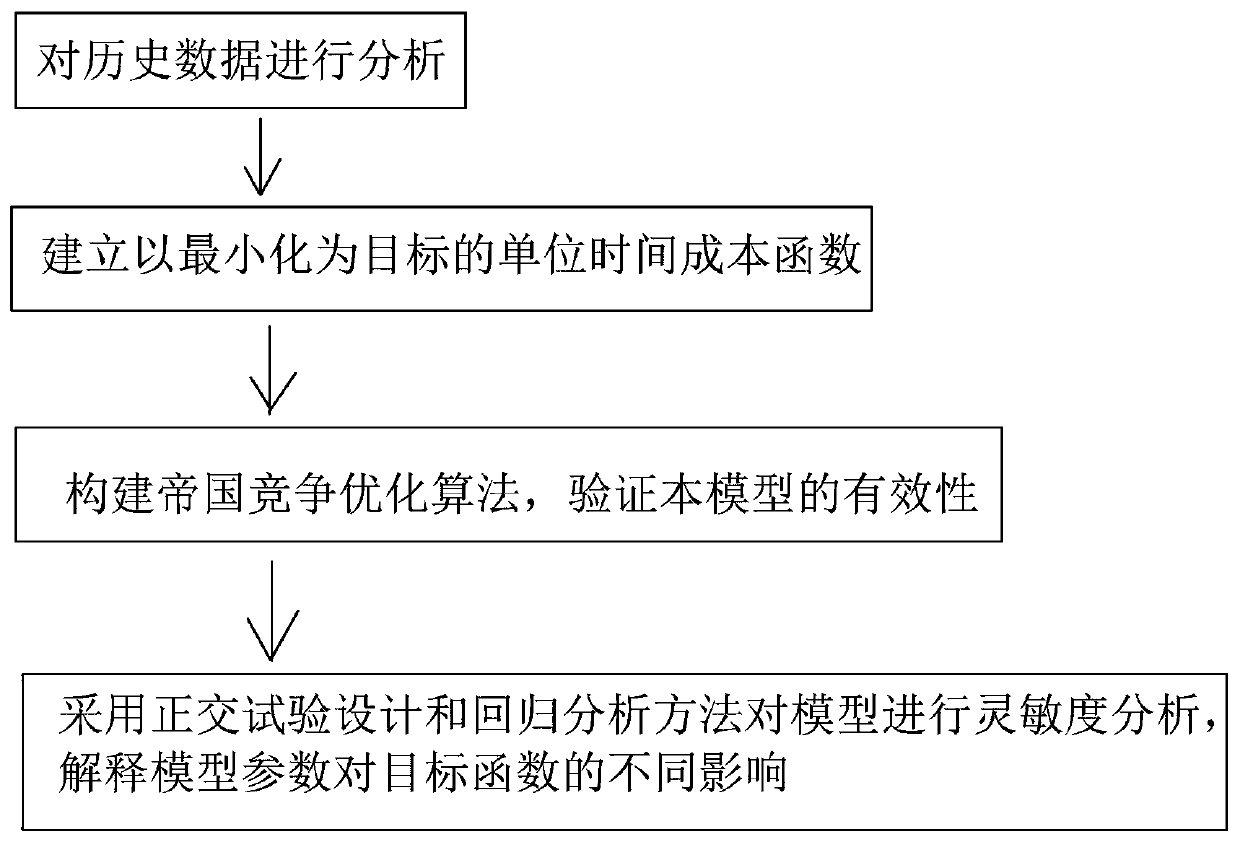

Method used

Image

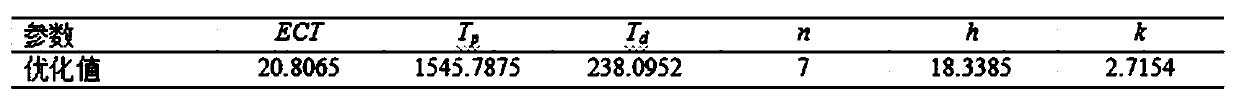

Examples

Embodiment Construction

[0029] Taking a test production system as an example, the specific implementation manner of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0030] Step 1: Consider that a production system only has two states of controlled and out of control. Whether the system operation is under control cannot be directly observed, but the system out of control will cause the deviation of the mean value X of quality characteristics. Therefore, the production process is monitored through the mean value control chart Can get better results. According to the principle of service life, due to the low probability of early failure of equipment and high equipment reliability, postponing the detection point of the control chart to a predetermined time point can effectively reduce the sampling cost and the total cost of the production process.

[0031] It is known that in each maintenance interval period, the time point u when the system turns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com