Patents

Literature

35 results about "Quality control charts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

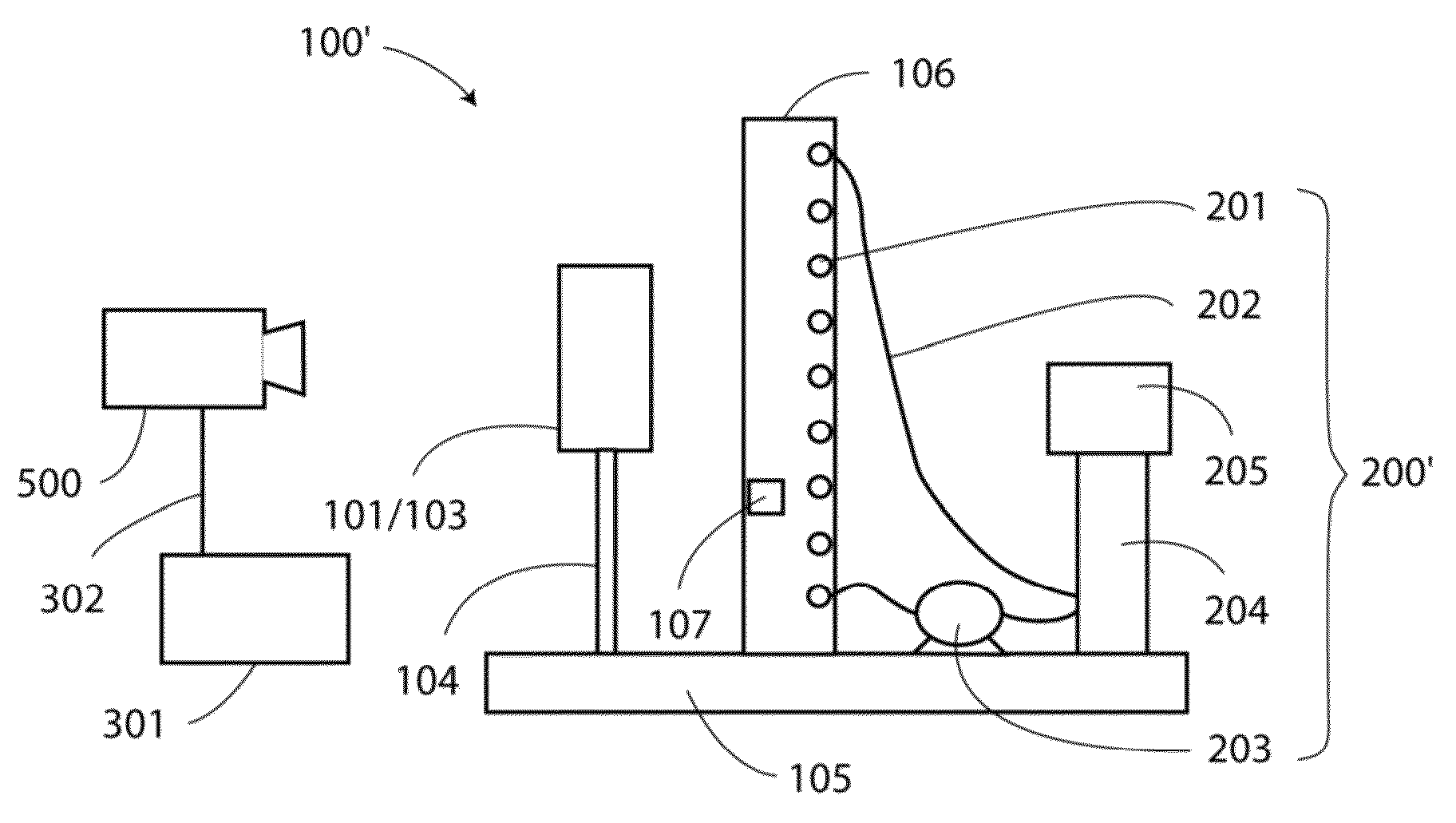

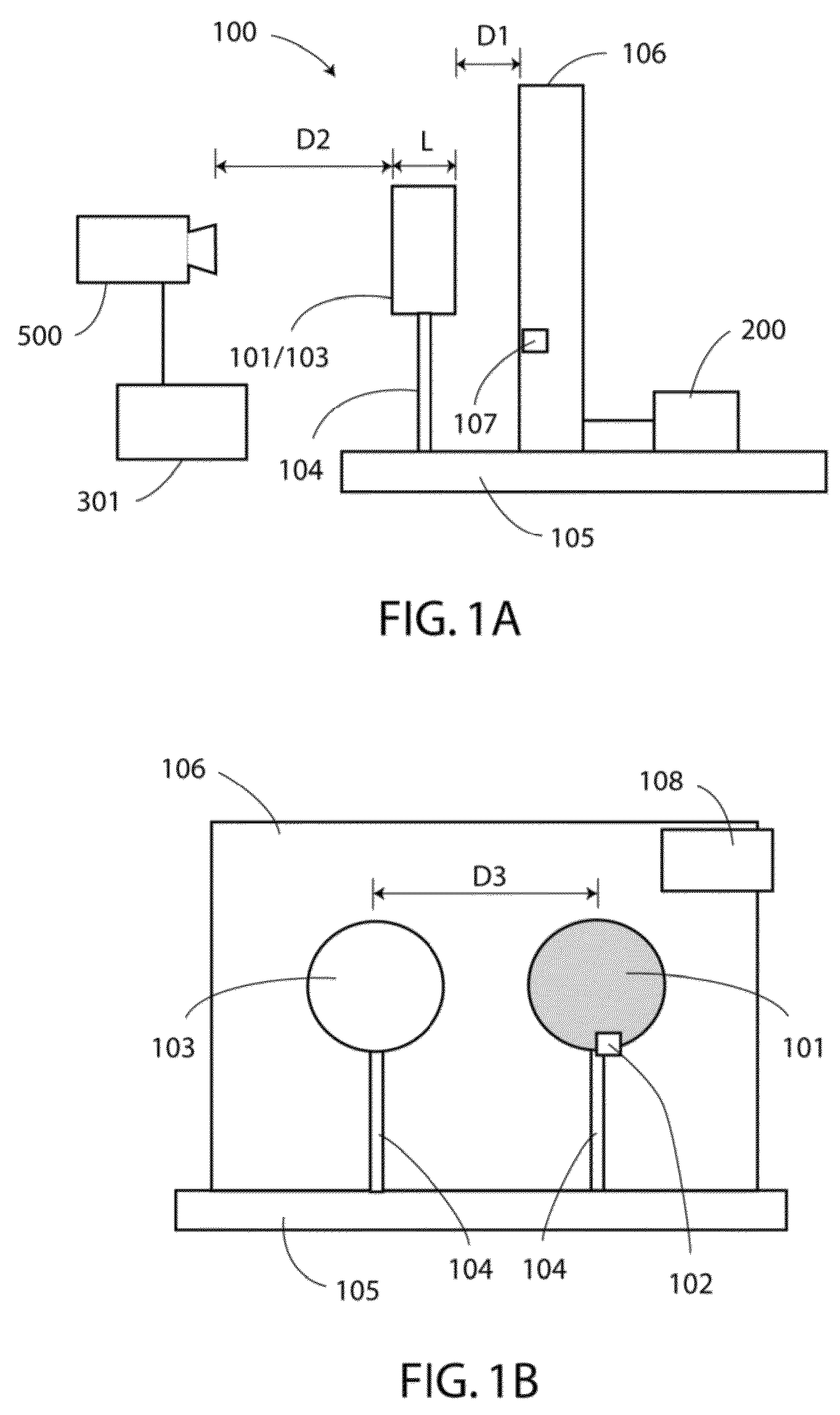

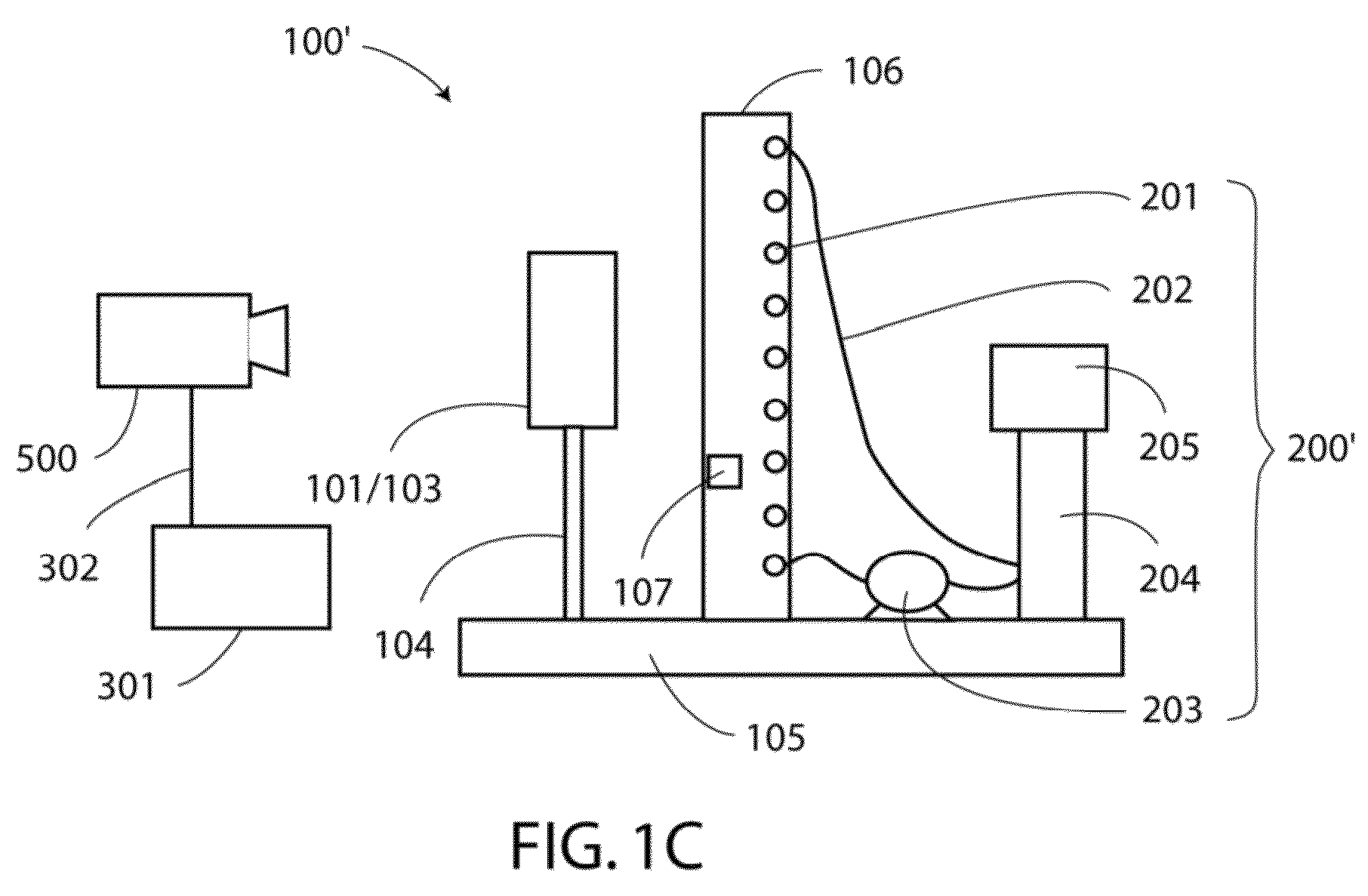

Calibration and quantification method for gas imaging camera

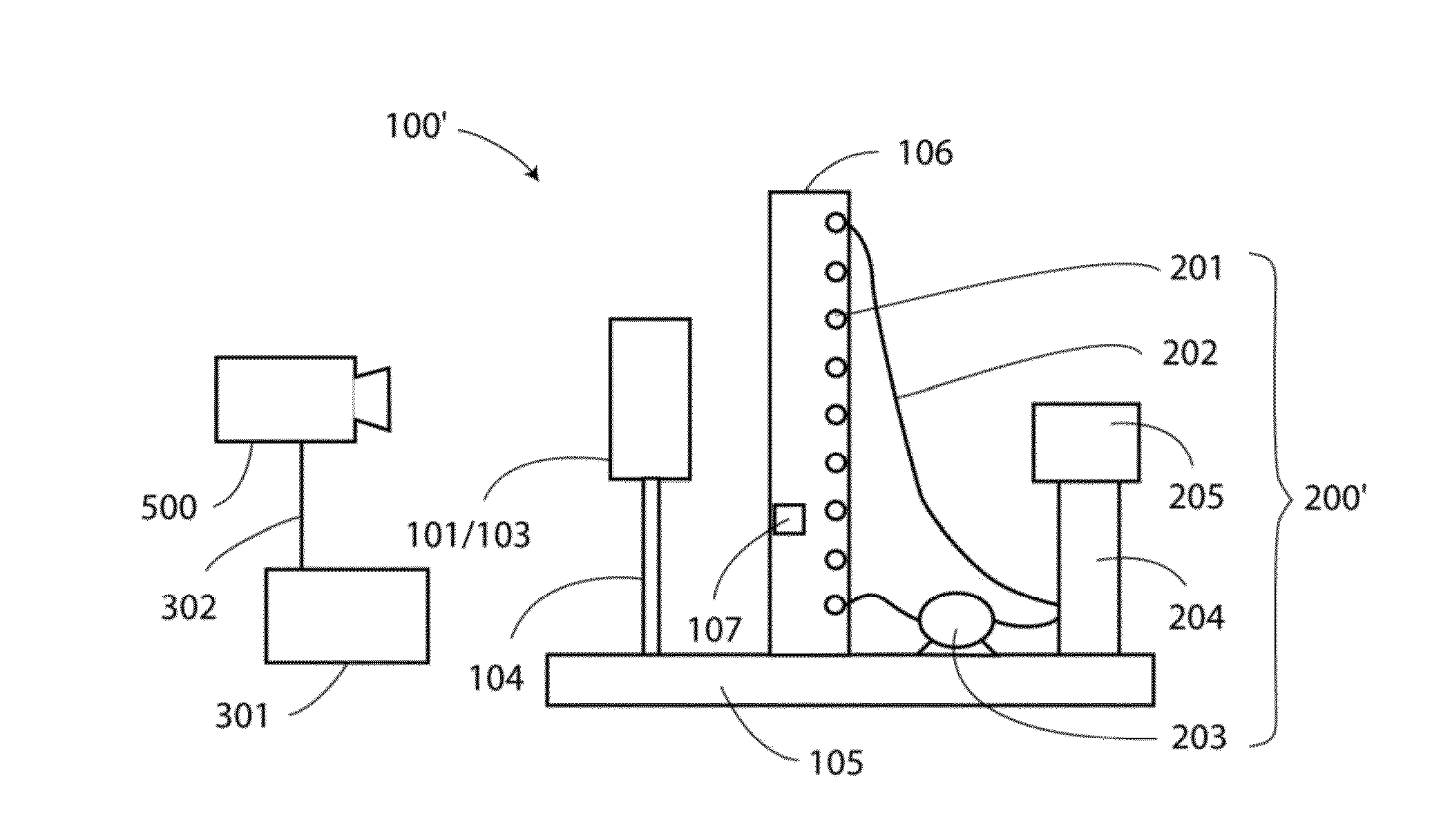

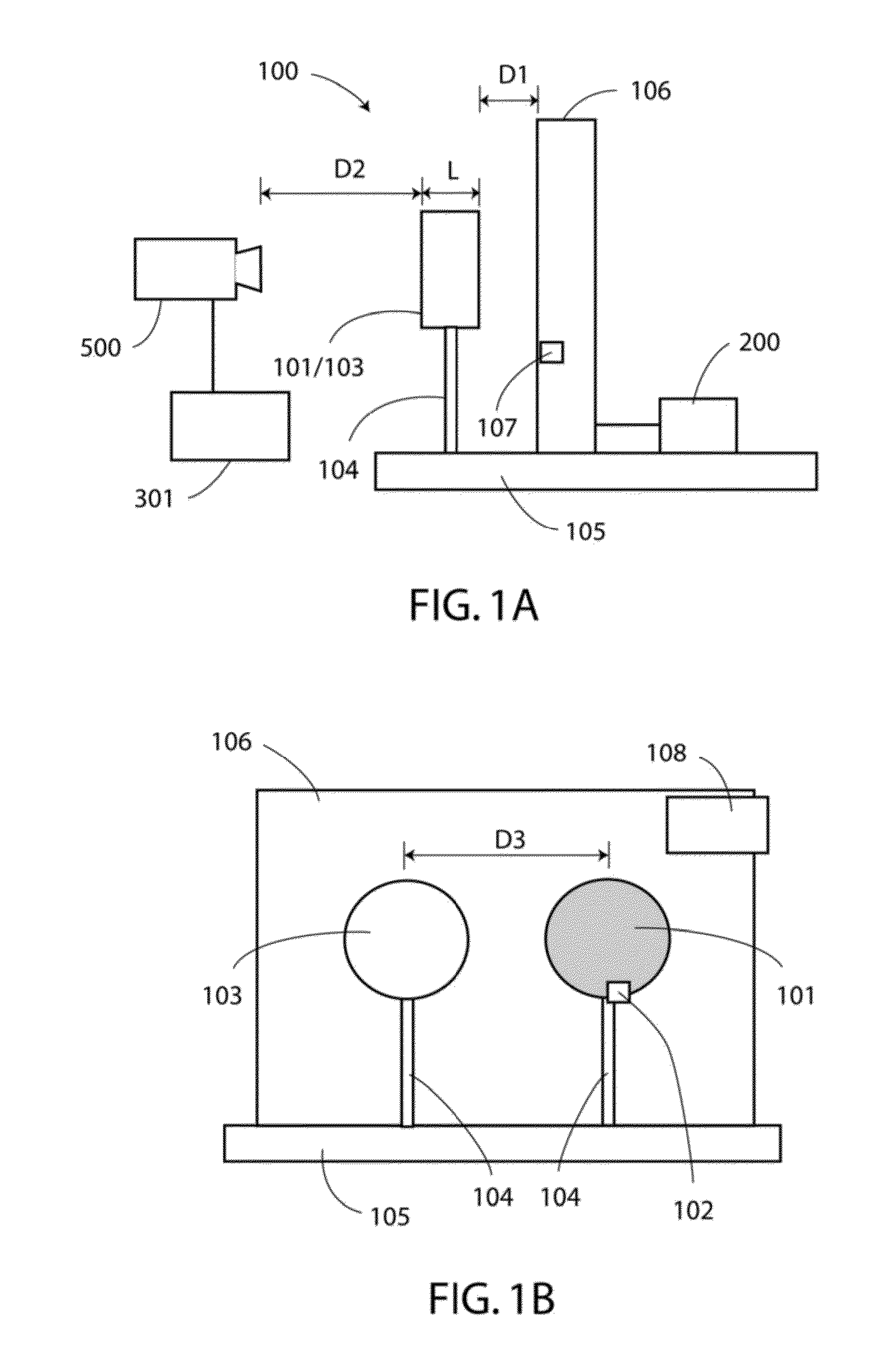

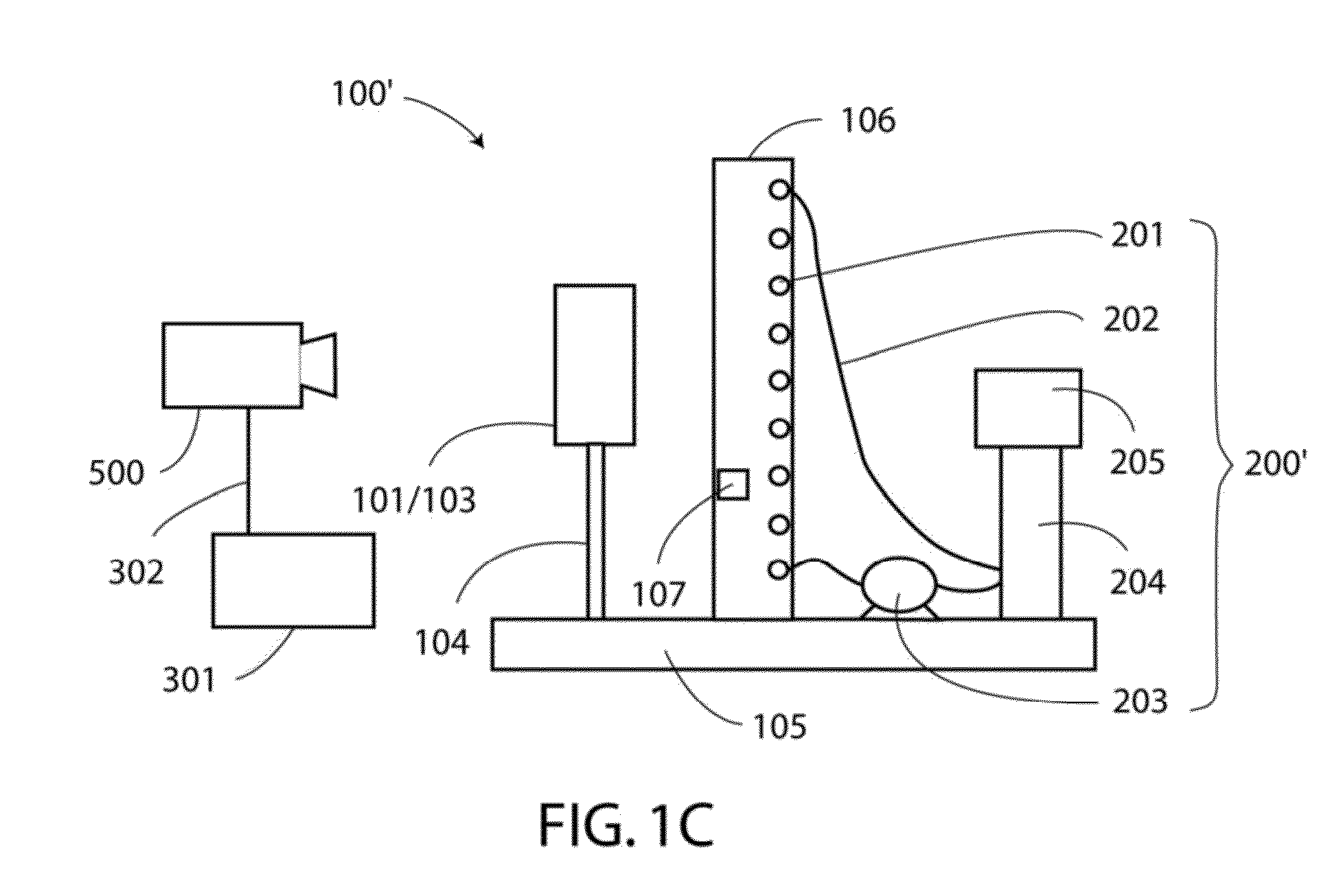

ActiveUS20140008526A1Television system detailsSensing radiation from gases/flamesConfocalQuality control charts

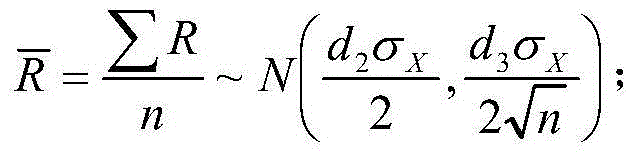

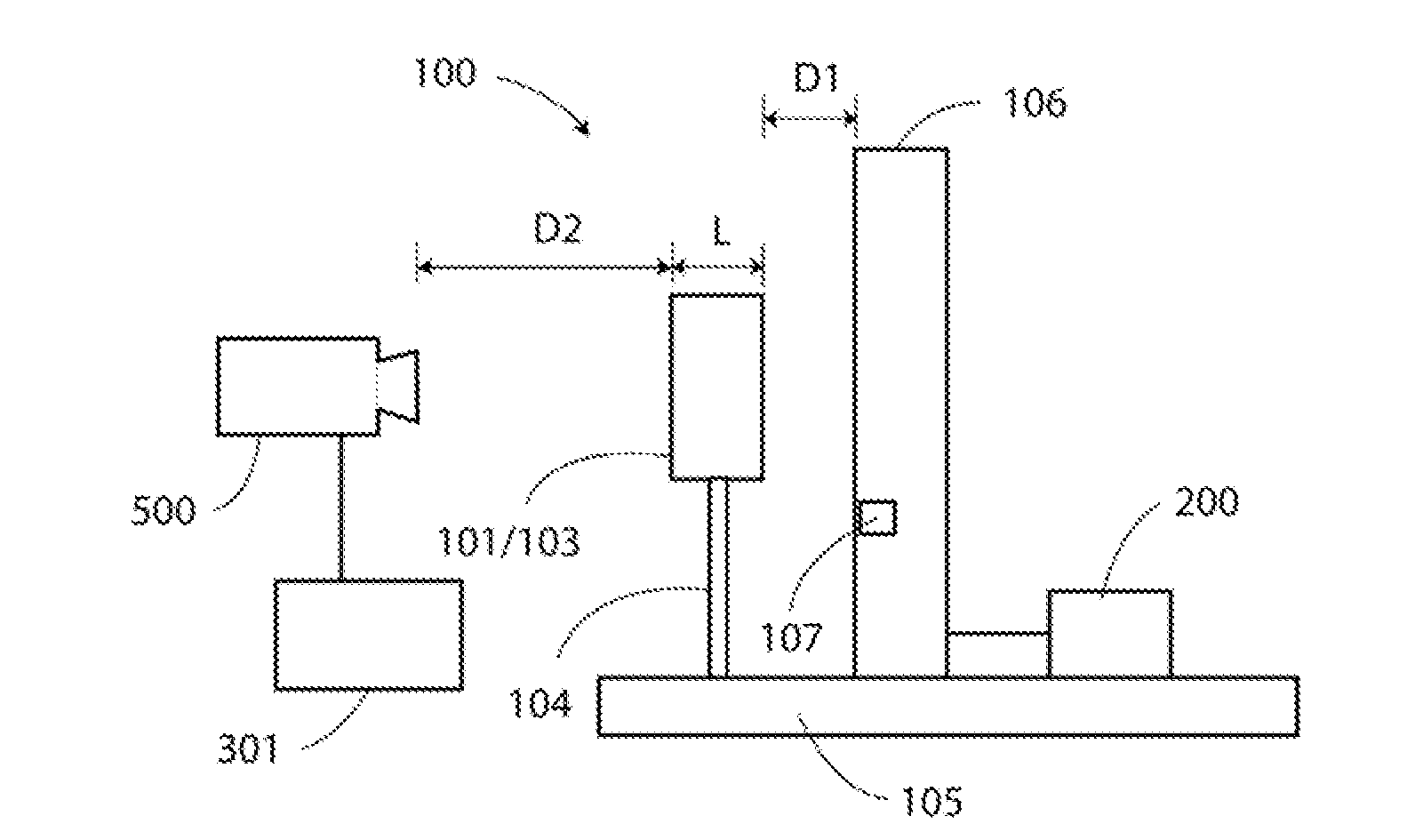

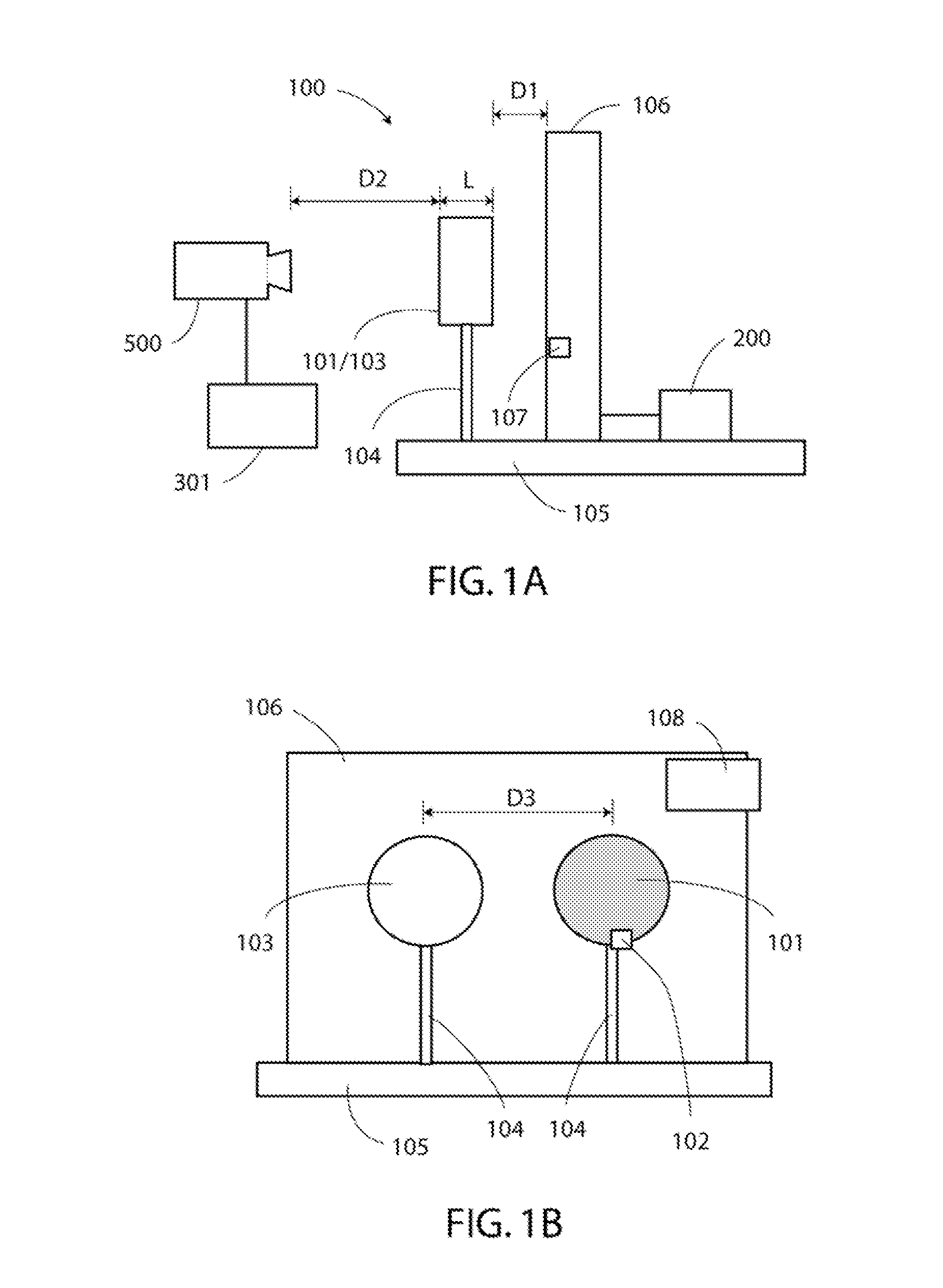

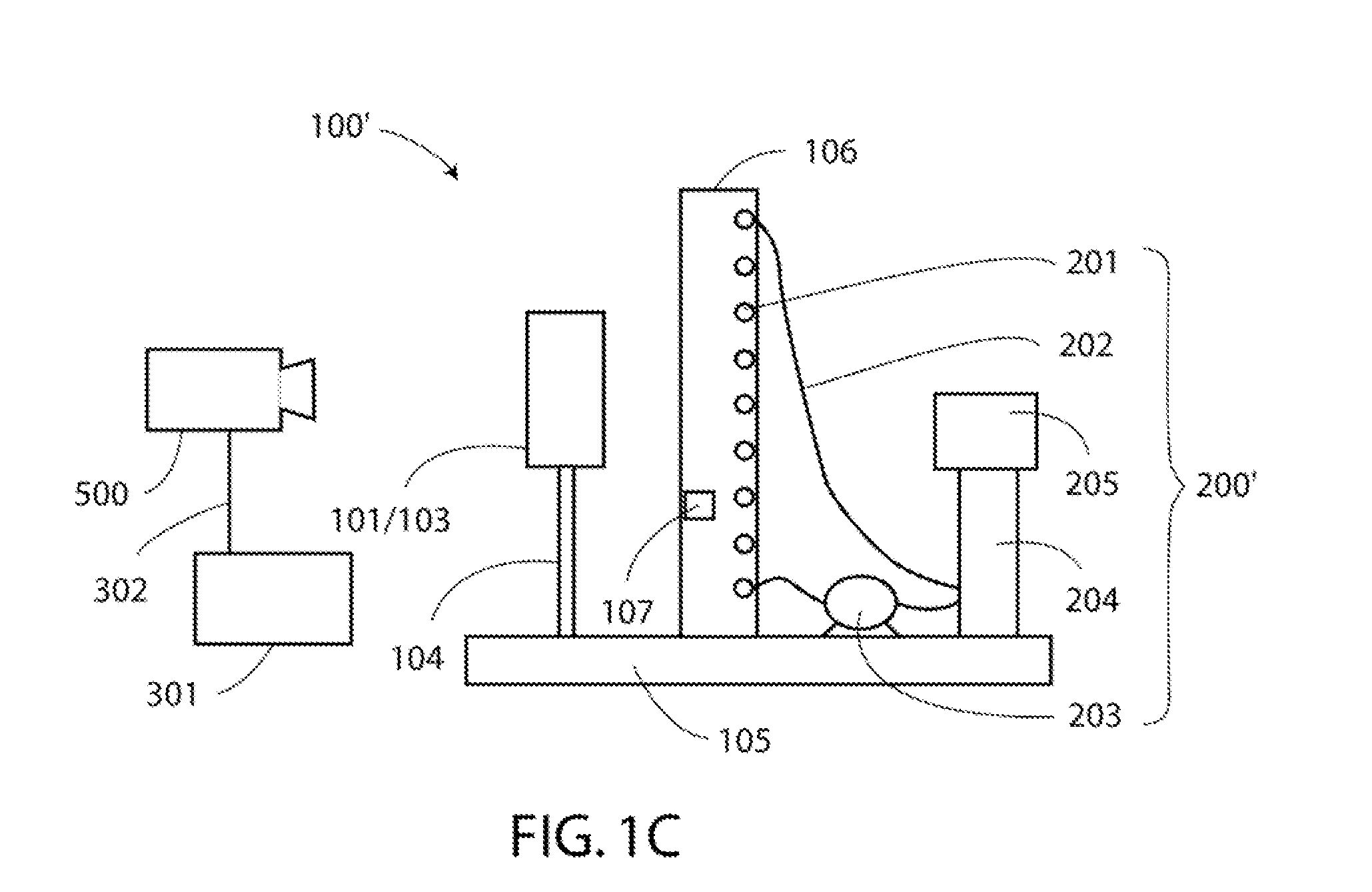

The calibration / verification system and method for gas imaging infrared cameras standardizes the procedures to objectively and consistently check performance of gas imaging infrared cameras. This system includes a background board maintaining a uniform temperature, a target cell filled with a target compound and disposed in front of the background board, a reference cell filled with a reference compound and disposed in front of the background board, and an analyzer coupled to the camera that captures images of the gas cell and the reference cell. The analyzer compares the intensity difference and the temperature difference of rays passing through the target cell and reference cell to a reference relationship data of a quality control chart to determine whether the camera is in a working condition. The method is further extended to provide a quantitative measurement of a hydrocarbon plume from a gas imaging infrared camera.

Owner:PROVIDENCE PHOTONICS

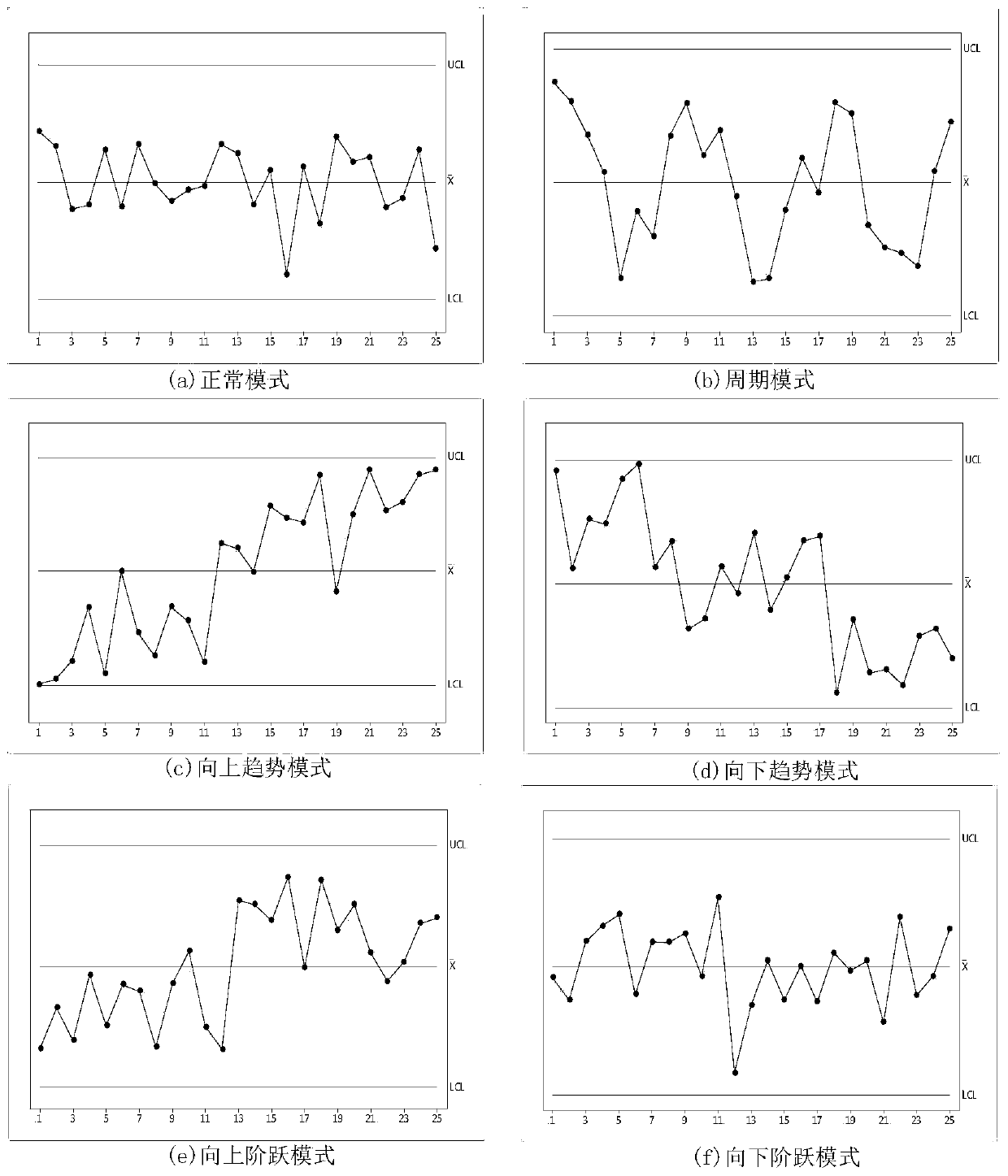

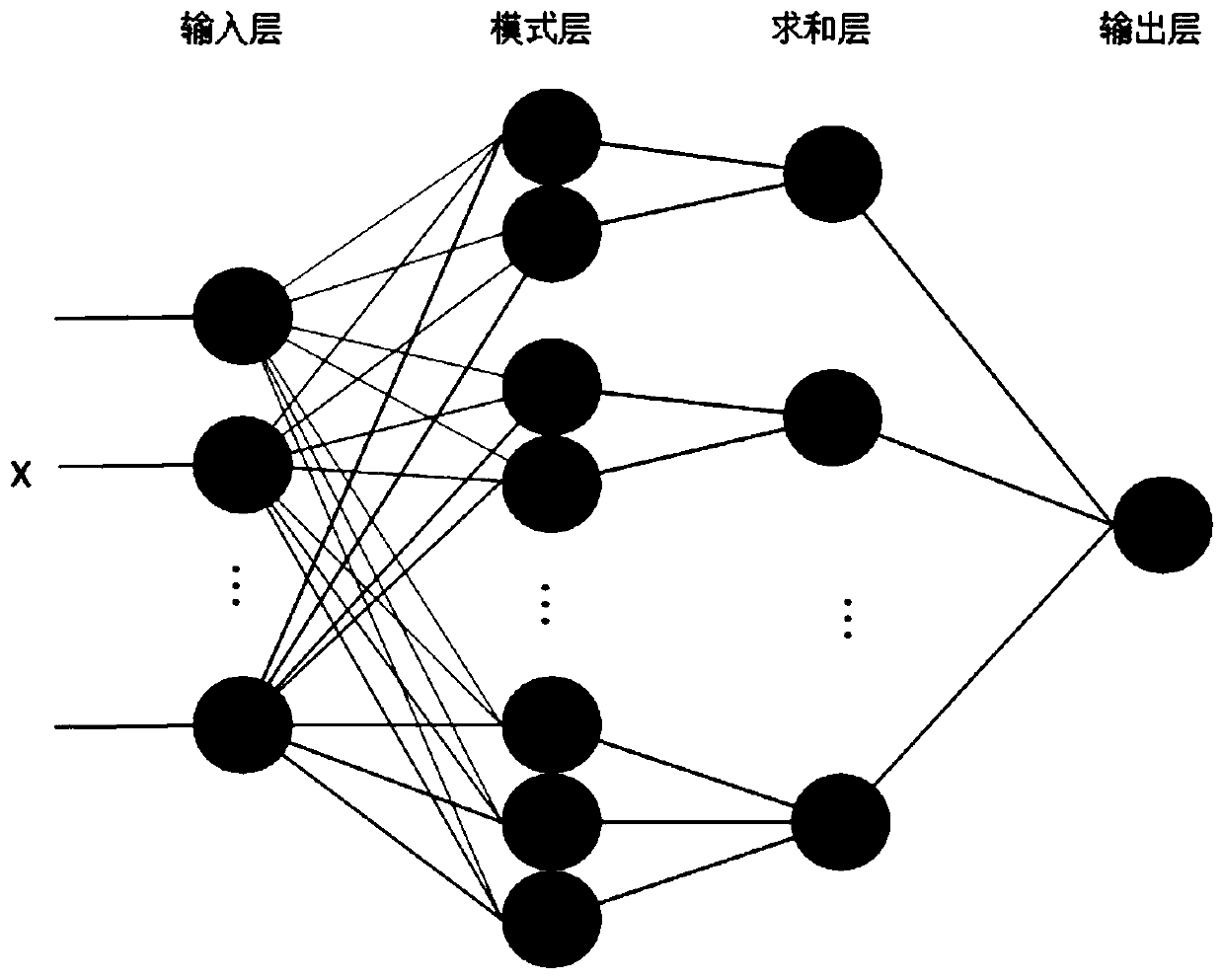

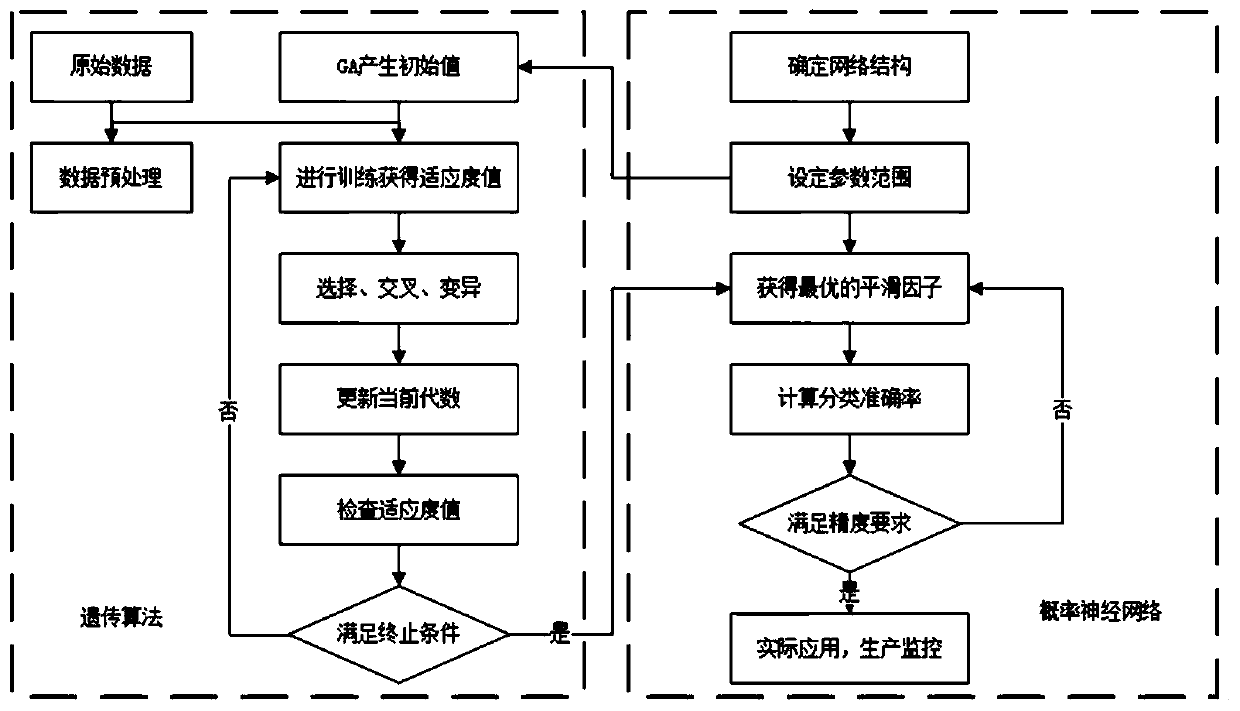

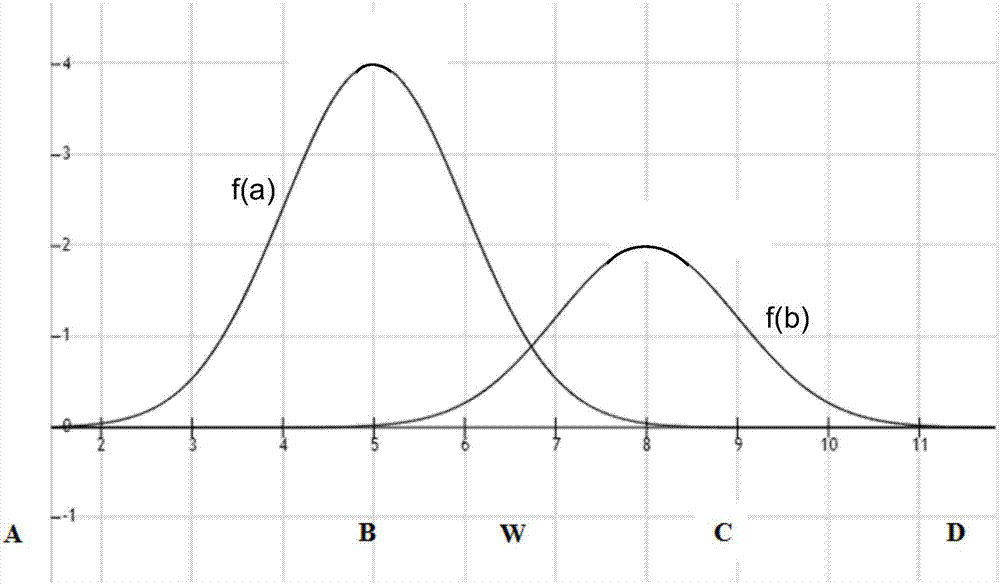

Quality control chart pattern recognition method based on improved genetic algorithm optimization

InactiveCN109919130AFast trainingFast recognitionGenetic modelsCharacter and pattern recognitionOriginal dataPrincipal component analysis

The invention provides a quality control chart pattern recognition method based on improved genetic algorithm optimization. The quality control chart pattern recognition method comprises the followingsteps: simulating various pattern characteristics of a control chart by using a Monte Carlo method; generating data of a corresponding mode through the parameter values; adopting the PCA principal component analysis method to carry out dimension reduction and denoising on the original data, main features of the data are extracted, shortening the training time of the model and improvintg the recognition accuracy; establishing a probabilistic neural network model, and carrying out pattern classification recognition by utilizing the characteristics of simple structure and convenient training; optimizing a main parameter smoothing factor of the probabilistic neural network by virtue of an improved single-objective optimization genetic algorithm; searching possible abnormal reasons from different aspects according to the identification result.The method solves the problems that all abnormal conditions cannot be monitored and recognized when an existing enterprise carries out quality control, effective abnormal information is difficult to find from a control chart, and appropriate measures cannot be taken to correct the abnormal conditions in the production process.

Owner:XI AN JIAOTONG UNIV

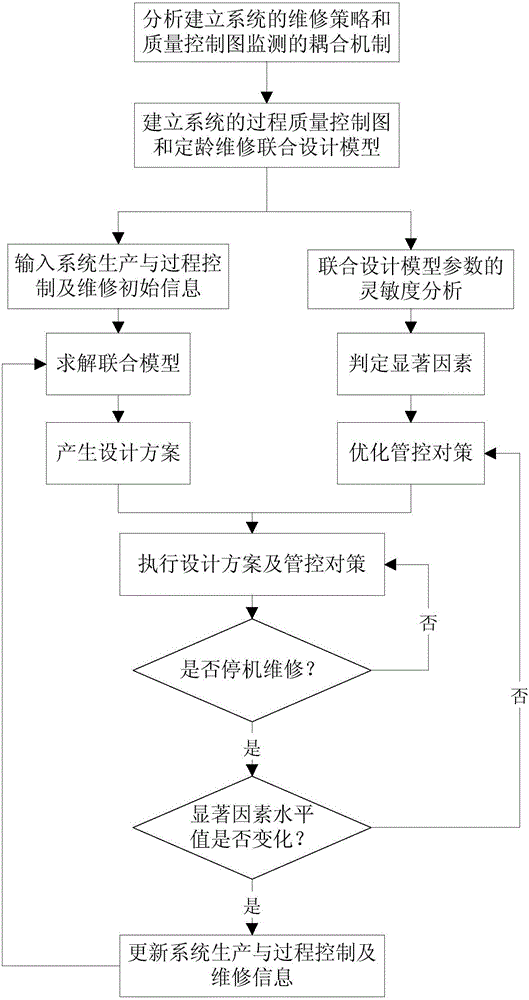

Dynamic optimization control method of process quality control graph and age-set maintenance combined design

ActiveCN106249709AIn line with the actual production situationAccurate dataTechnology managementTotal factory controlProcess qualityCountermeasure

The invention provides a dynamic optimization control method of a process quality control graph and age-set maintenance combined design, and the method is used to realize continuous optimization of a process quality control graph and age-set maintenance combined design scheme of a production system so as to minimize the integrated cost of production operation. The method comprises that 1) a process quality control graph and age-set maintenance combined design model, aimed at minimizing the integrated cost of production operation, of the production system is constructed; 2) a process quality control graph and age-set maintenance combined design scheme is solved according to the combined design model by utilizing a genetic algorithm; 3) an initial scheme and a cost management countermeasure are executed, and when shut-down maintenance is triggered during system operation, whether the cost level of a significance influential factor is changed obviously is determined; and 4) according to a determination result, the execution scheme is optimized and enforced, a new cost-reducing countermeasure is provided and the original design scheme are executed if there is no change, and if there is change, the design scheme needs to be optimized, and the design scheme is solved again according to a change result by utilizing the genetic algorithm, and execution of the scheme is determined.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

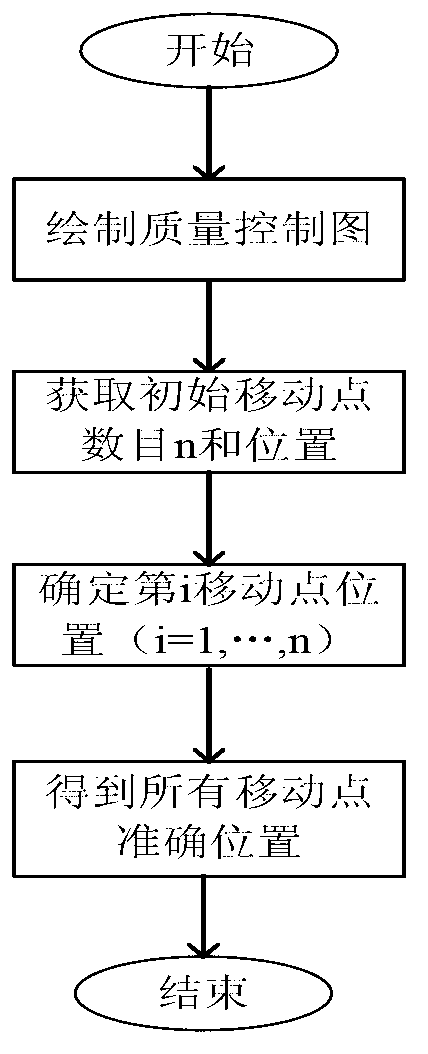

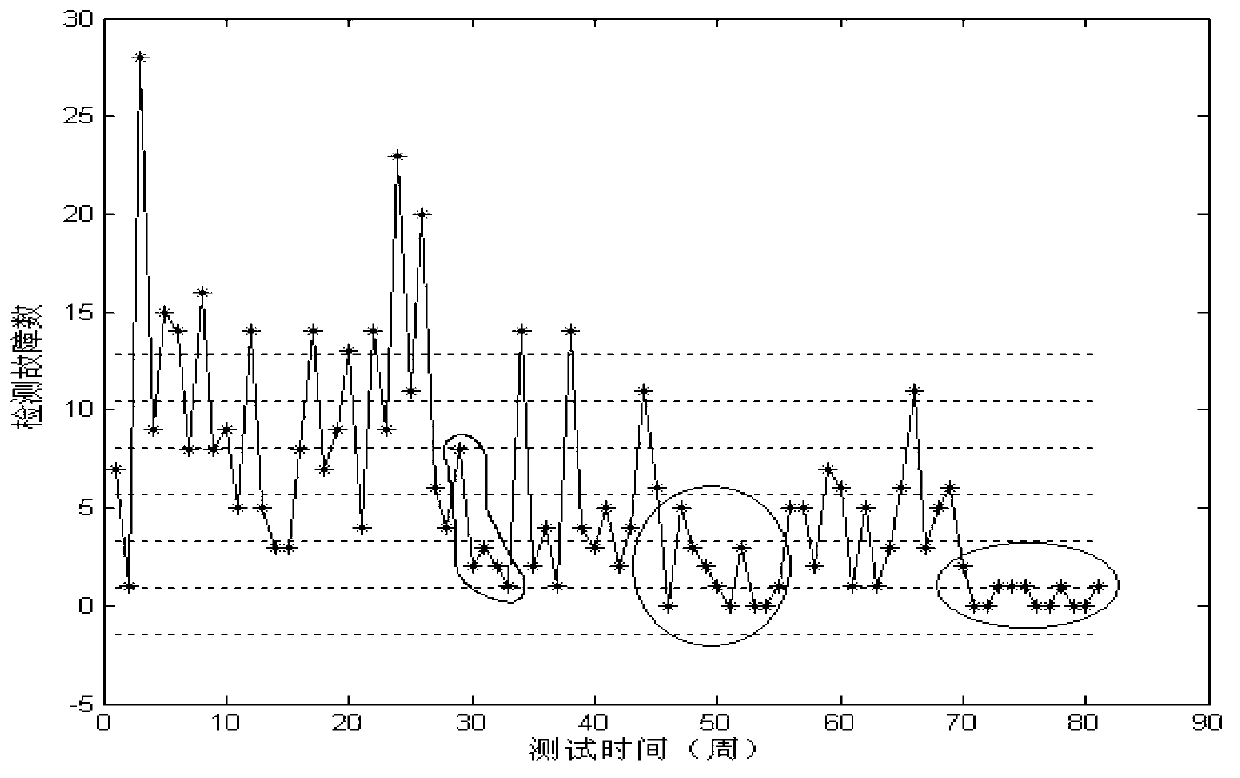

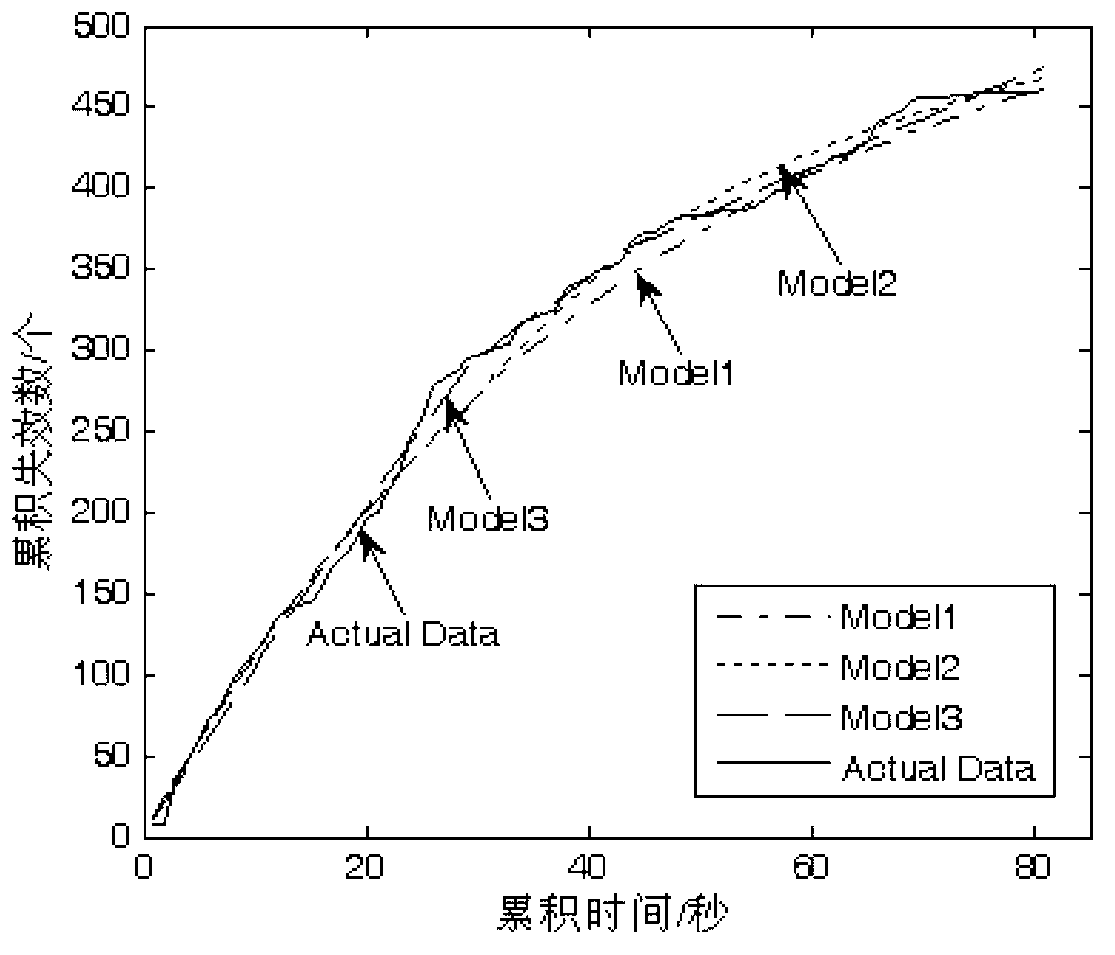

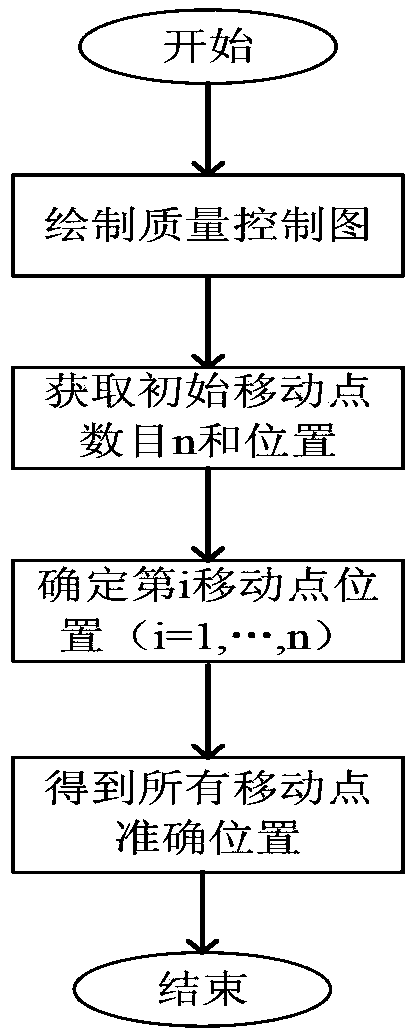

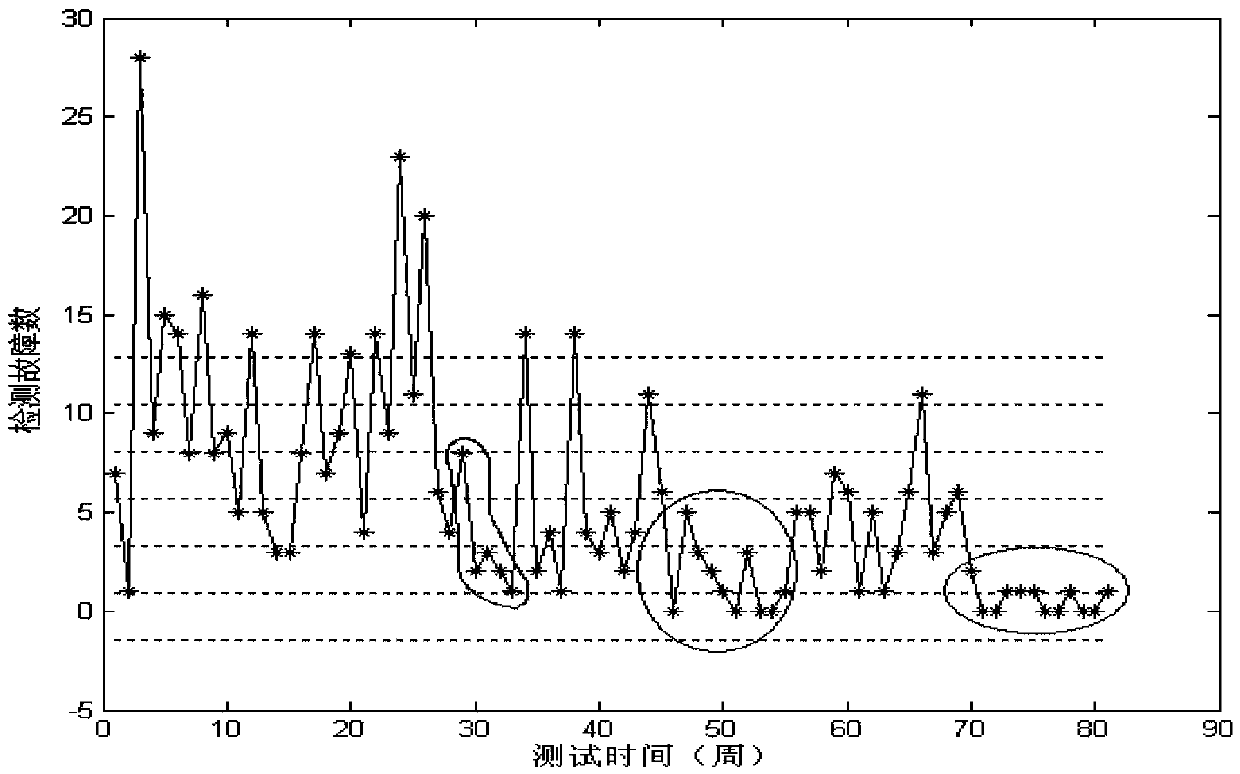

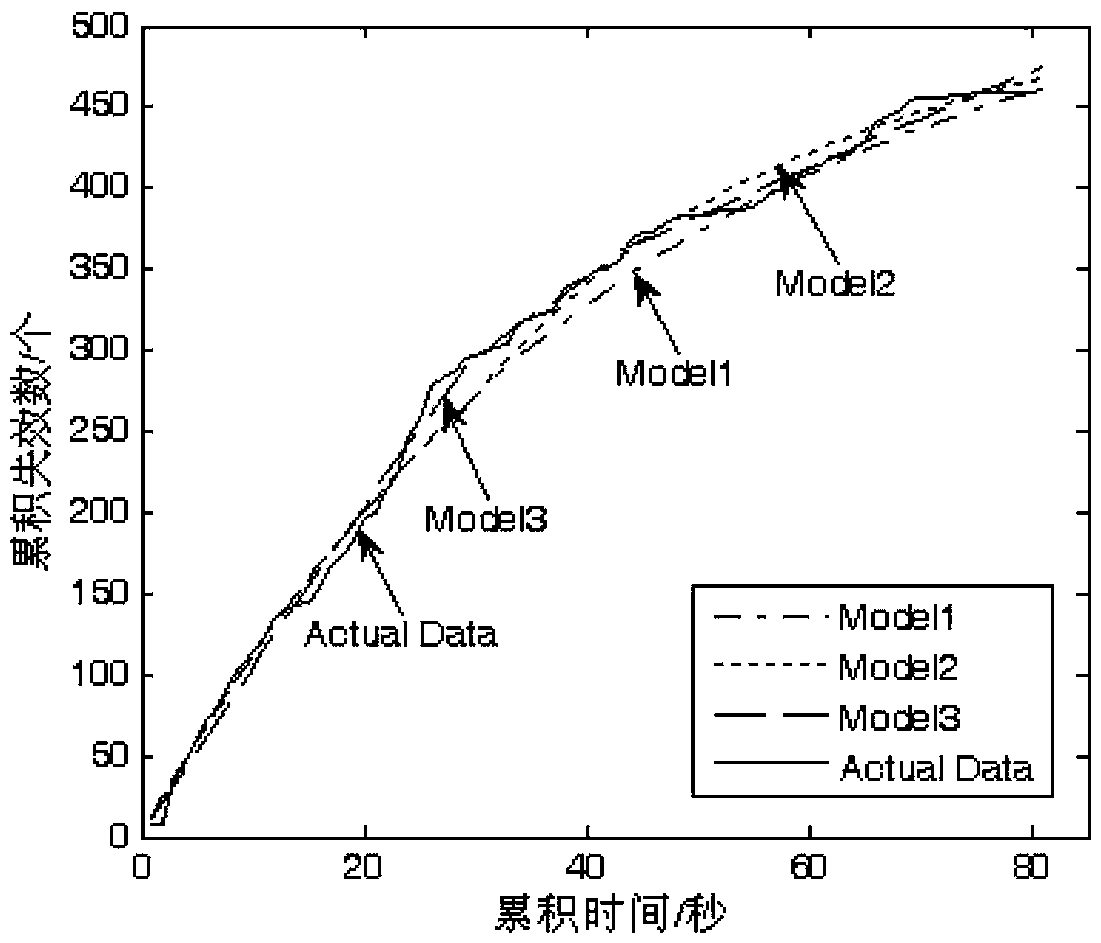

Estimation method for mobile points of software reliability growth model

ActiveCN103345443AJudgment criteriaPreliminary judgment is accurateSoftware testing/debuggingEstimation methodsSoftware system

The invention discloses an estimation method for mobile points of a software reliability growth model. The estimation method comprises the first step of drawing a quality control chart according to software system actual failure data, the second step of obtaining initial mobile points according to the quality control chart and a mobile point judging criterion, and the third step of obtaining the accurate positions of the mobile points by using a gradual adjustment method. According to the estimation method for the mobile points of the software reliability growth model, the mobile point judging criterion is provided, the preliminary judgment of the mobile points are more accurate, the number, obtained in an estimated mode, of the mobile points is accurate, and positional deviation is small. The estimation method for the mobile points of the software reliability growth model is a new mobile point estimation method, and the problem that the position estimation of the mobile points is not accurate is solved by using the gradual adjustment method on the basis that the number and the positions of the initial mobile points are obtained by using the quality control chart.

Owner:HARBIN ENG UNIV

Calibration and quantification method for gas imaging camera

ActiveUS9225915B2Television system detailsSensing radiation from gases/flamesTemperature differenceQuality control charts

The calibration / verification system and method for gas imaging infrared cameras standardizes the procedures to objectively and consistently check performance of gas imaging infrared cameras. This system includes a background board maintaining a uniform temperature, a target cell filled with a target compound and disposed in front of the background board, a reference cell filled with a reference compound and disposed in front of the background board, and an analyzer coupled to the camera that captures images of the gas cell and the reference cell. The analyzer compares the intensity difference and the temperature difference of rays passing through the target cell and reference cell to a reference relationship data of a quality control chart to determine whether the camera is in a working condition. The method is further extended to provide a quantitative measurement of a hydrocarbon plume from a gas imaging infrared camera.

Owner:PROVIDENCE PHOTONICS

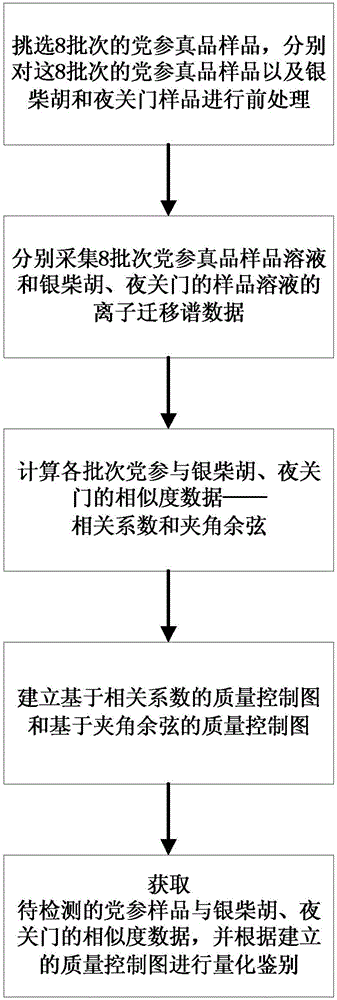

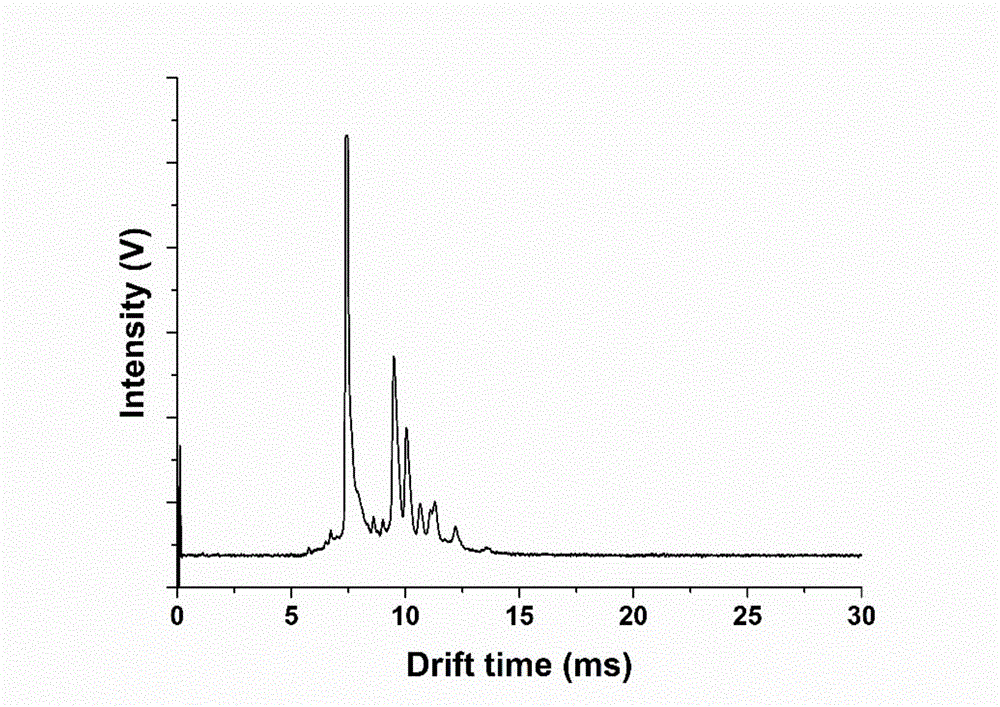

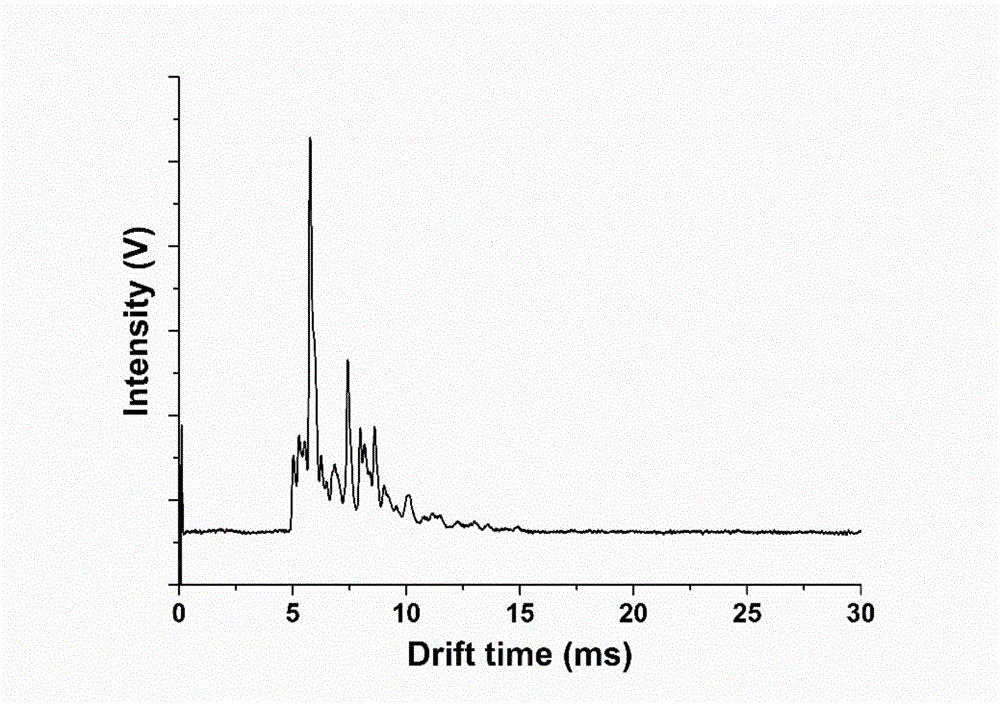

Method for identifying traditional Chinese medicinal materials and easily confused counterfeit medicines on the basis of ion mobility spectrometry and similarities

InactiveCN106483187ASolve the current research status that quality and safety supervision is difficult to controlReduce dosageMaterial analysis by electric/magnetic meansMedicineQuality control charts

The invention discloses a method for identifying traditional Chinese medicinal materials and easily confused counterfeit medicines on the basis of ion mobility spectrometry and similarities. The ion mobility spectrometry is used as an analysis and test means, quantification processes include similarity computation and quality control charts, and the quantification method applicable to controlling the quality of the traditional Chinese medicinal materials can be provided. The method has the advantages that the method gives priority to quantitative evaluation rather than qualitative analysis dominant in traditional quality control identification of the traditional Chinese medicinal materials and is speedy, accurate and capable of achieving quantitative output, so that a novel evaluation thought is provided for the quality safety of the traditional Chinese medicinal materials in China, and the method is of important significance to quality control guarantee and clinical medication safety of the traditional Chinese medicinal materials.

Owner:王海燕 +3

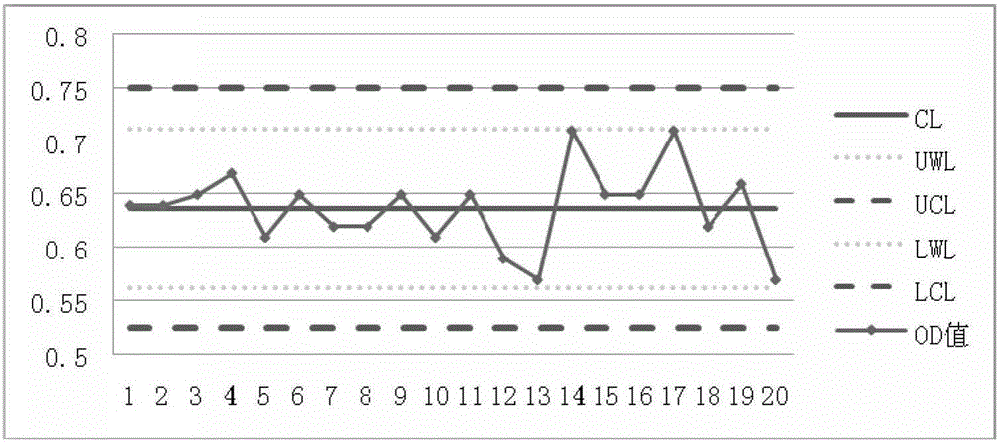

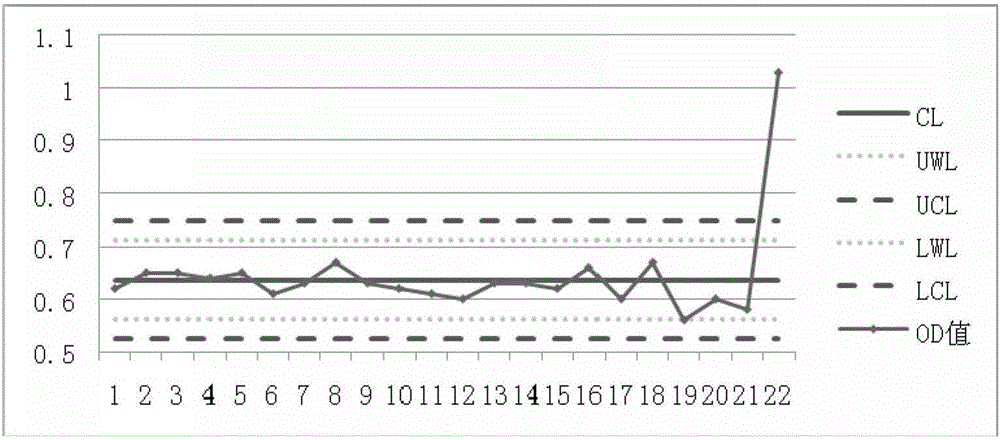

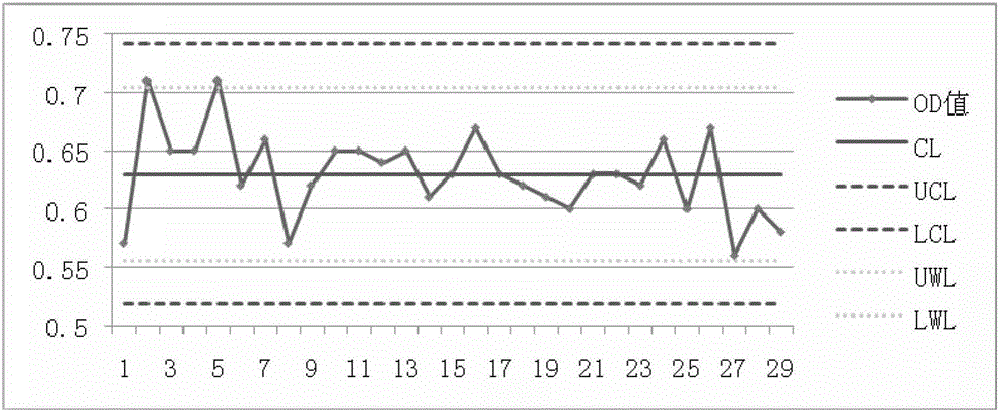

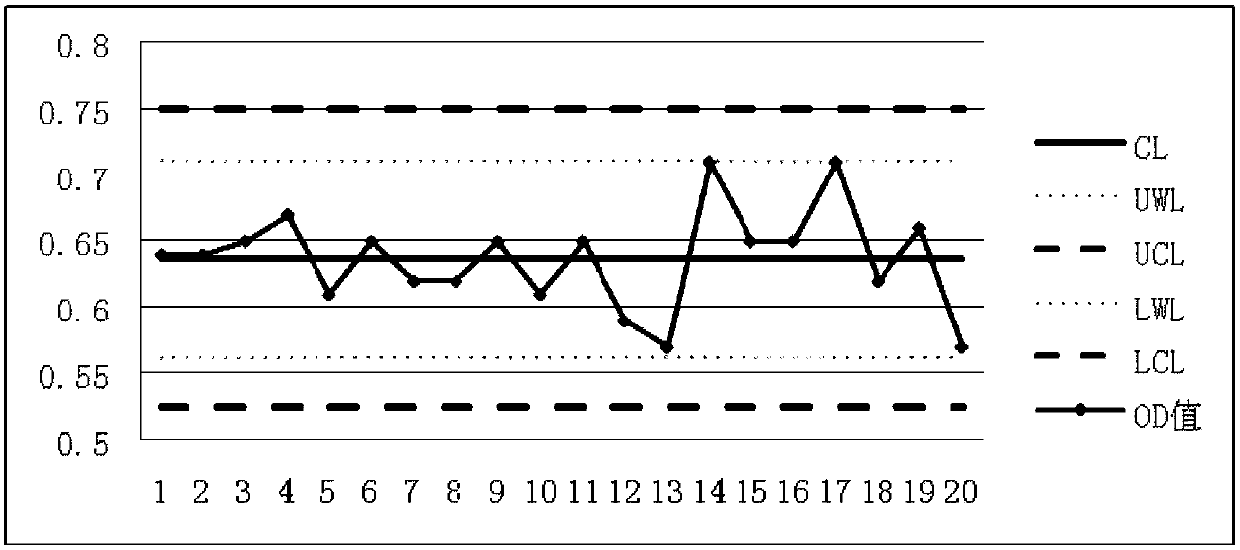

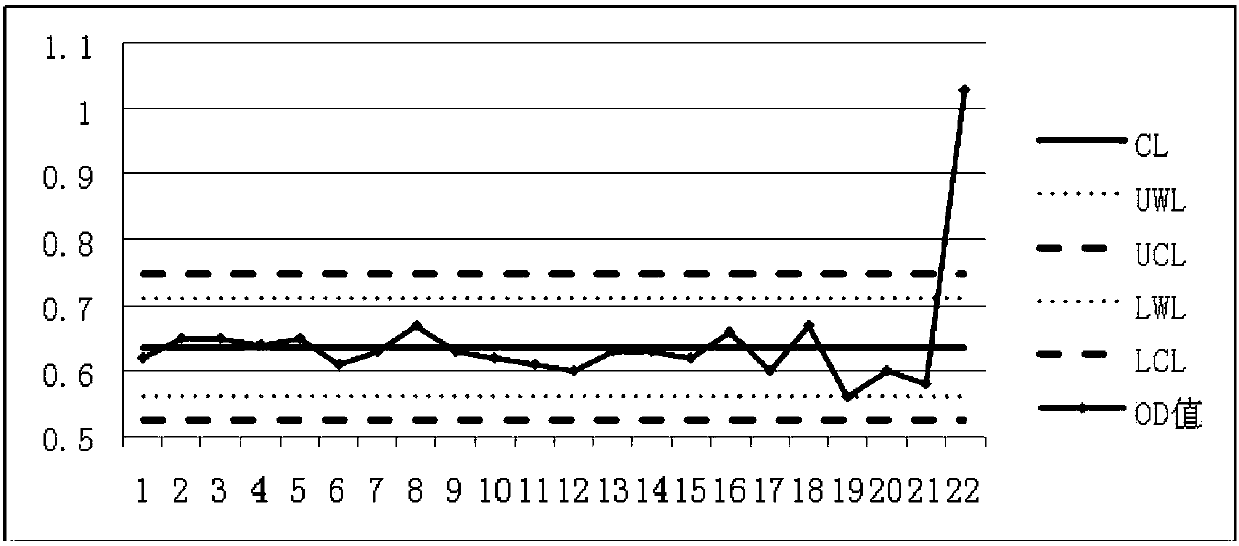

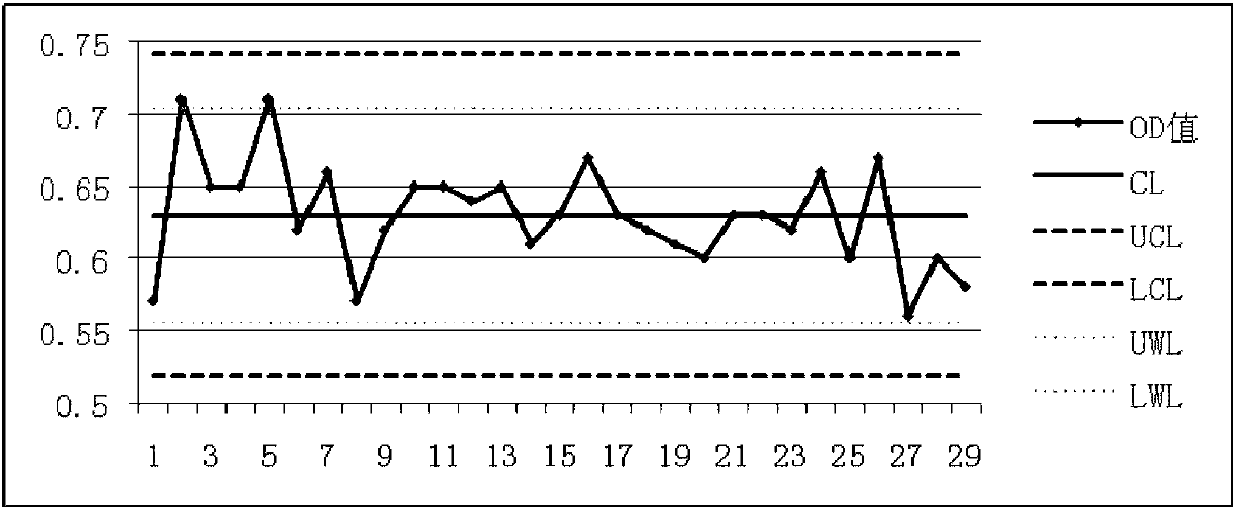

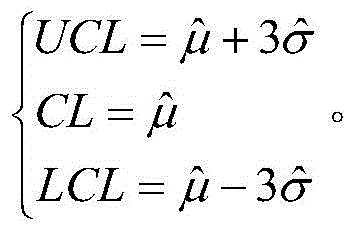

Building method and application of brucellosis tube agglutination test quality control chart

InactiveCN106053782AHigh precisionEasy to controlDisease diagnosisBiological testingControl powerTest quality

The invention discloses a building method and application of a brucellosis tube agglutination test quality control chart. The building method and application has the advantages that the method applies the quality control chart to a tube agglutination test in an exploration and innovation manner, an optical density value is used as the control value to obtain an object controlled by the test, and a new statistical manner and reference are provided for the process control in the field of animal quarantine; in addition, during the application process of the quality control chart, the quality control chart can be regulated and optimized at any time along with the accumulation of test data so as to increase the precision and control power of the quality control chart.

Owner:BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU INSPECTION & QUARANTINE TECH CENT

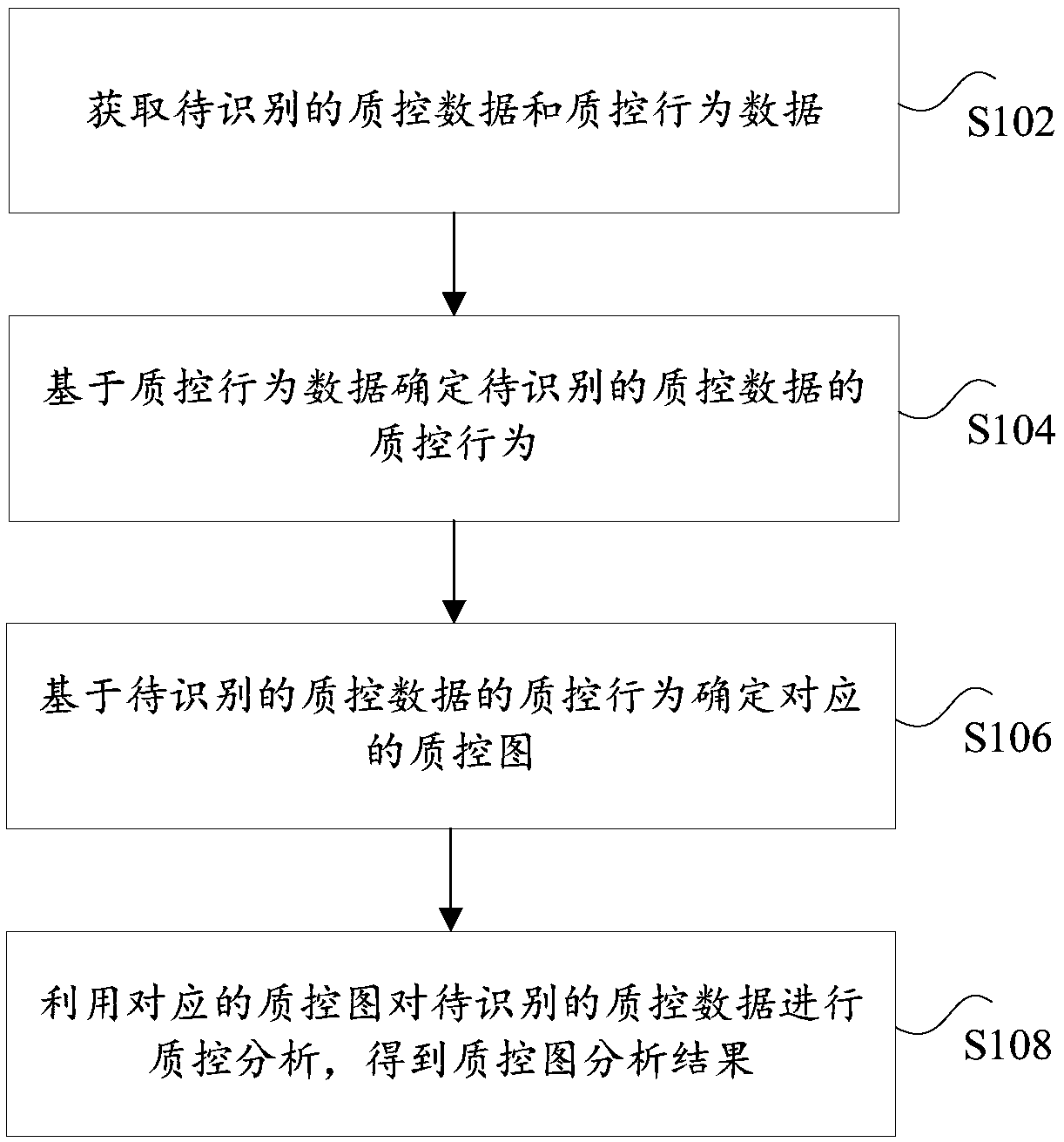

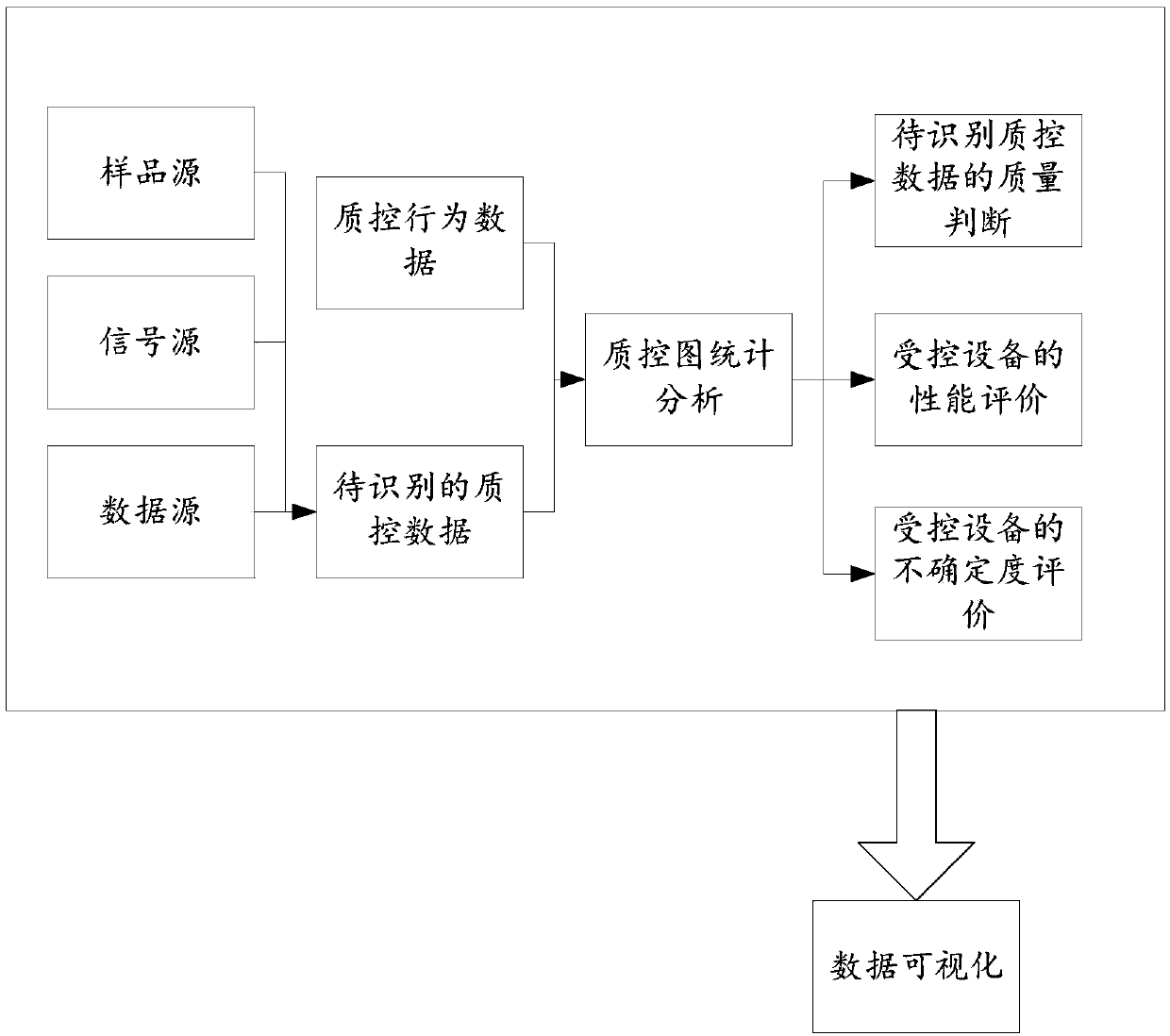

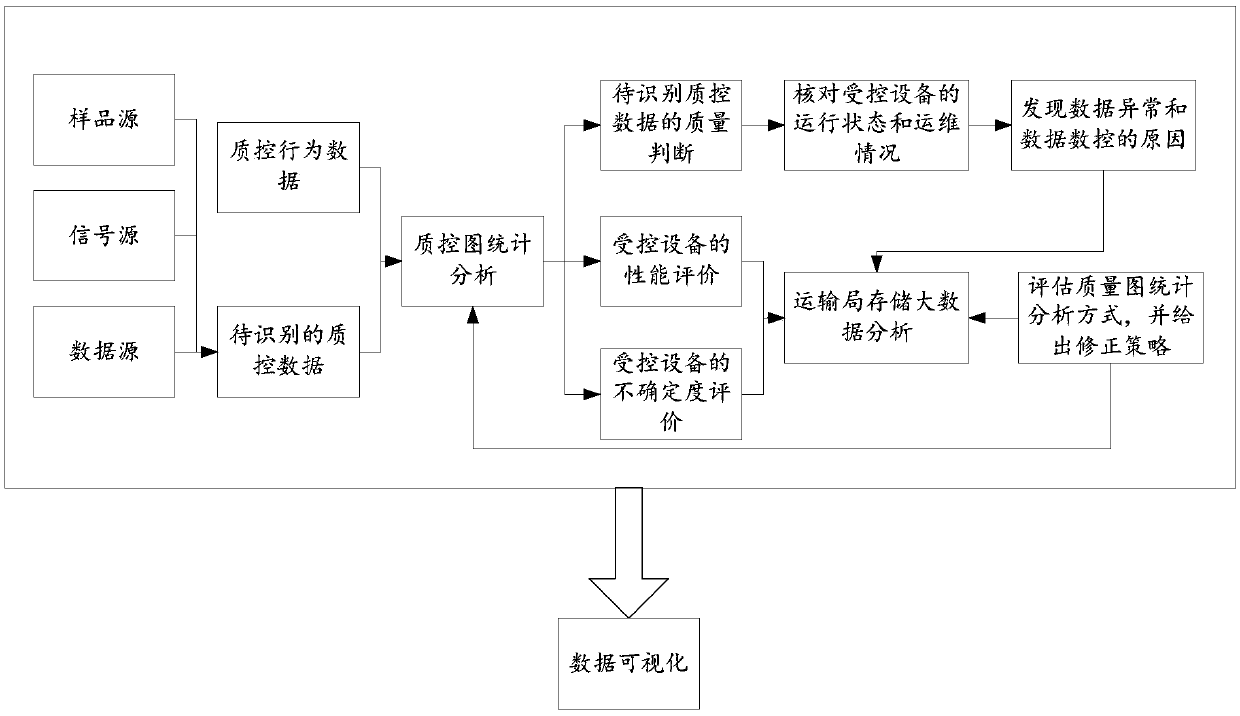

A quality control method and device for an environment monitoring instrument

InactiveCN109685458ARealize the integrated solution of automatic quality controlIntensive and efficient operation and maintenanceOffice automationEnvironmental monitorQuality control

The invention provides a quality control method and device for an environment monitoring instrument, and relates to the technical field of automatic quality control, and the method comprises the steps: obtaining to-be-identified quality control data and quality control behavior data, and enabling the to-be-identified quality control data to be data obtained after the quality control processing ofa monitoring result of controlled equipment; Determining a quality control behavior of the to-be-identified quality control data based on the quality control behavior data; Determining a correspondingquality control graph based on the quality control behavior of the to-be-identified quality control data; And carrying out quality control analysis on the quality control data to be identified by using the corresponding quality control graph, wherein the quality control chart analysis result is used for determining at least one of the following conditions: the monitoring data condition to be subjected to quality judgment, the performance of the controlled equipment and the uncertainty of the controlled equipment, and the technical problems that an existing quality control method is low in automation degree and poor in practicability are solved.

Owner:BEIJING WANWEIYINGCHUANG TECH

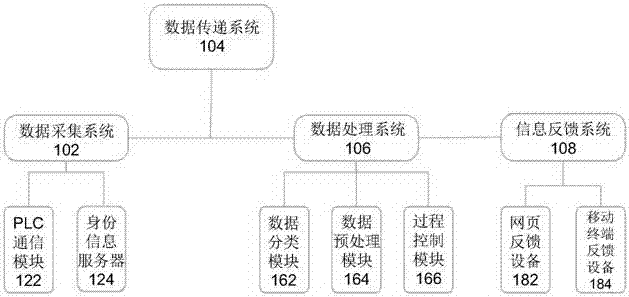

Assembly line product information collection method and collection device

InactiveCN107368056AImprove collection efficiencyEasy to FeedbackTotal factory controlProgramme total factory controlData acquisitionAssembly line

The invention discloses an assembly line product information collection device which includes a data collection system, a data transmission system, a data processing system and an information feedback system. The data collection system collects the identity information of an assembly line product. The data transmission system exchanges data with the work stations on the assembly line, and the work stations on the assembly line collect field data. The data processing system acquires the field data collected by the work stations on the assembly line through the data transmission system, and processes the field data to generate result data, wherein the result data includes a quality control chart established and optimized based on the field data. The information feedback system feeds back the result data generated by the data processing system to a remote terminal. The invention further discloses an assembly line product information collection method. Through the assembly line product information collection device and the collection method of the invention, the efficiency of information collection can be improved, convenient input, statistics and feedback can be realized, the first-pass yield of goods receipt is improved, and the rework rate and the process cost are reduced.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

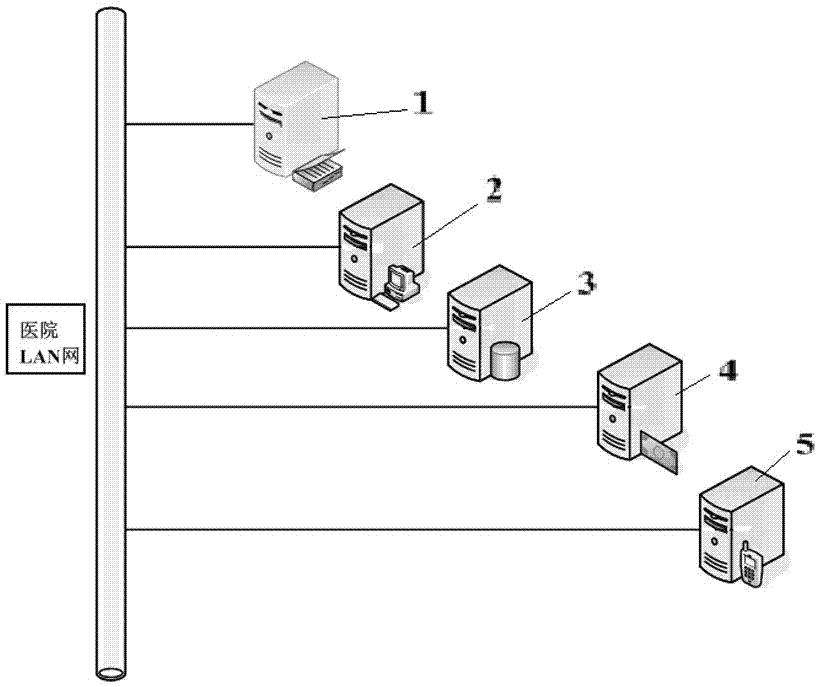

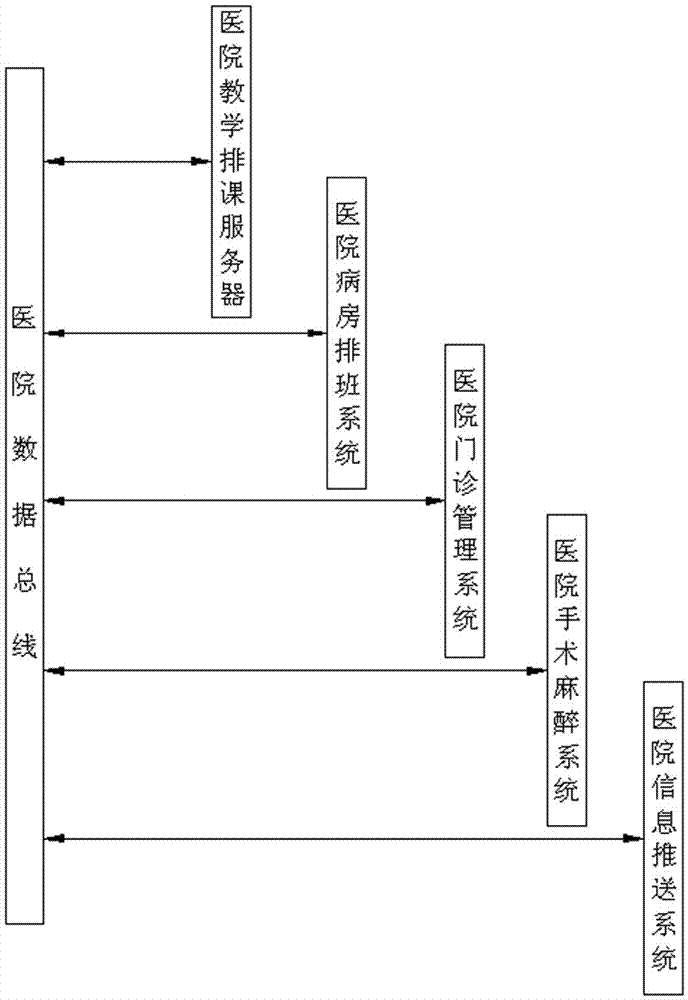

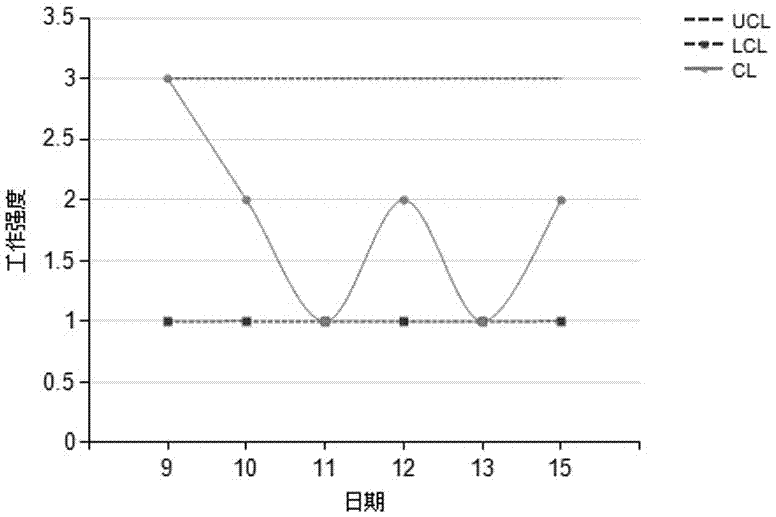

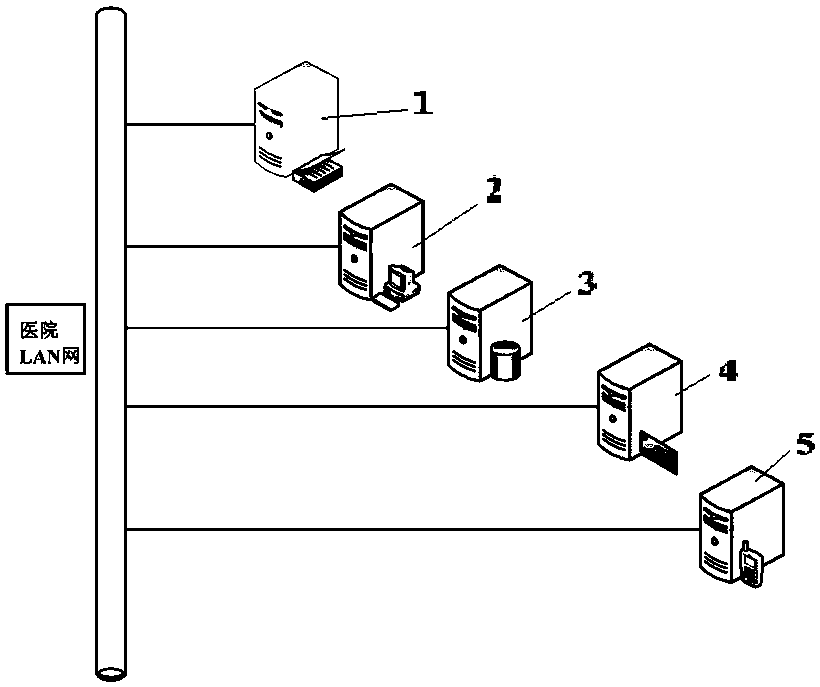

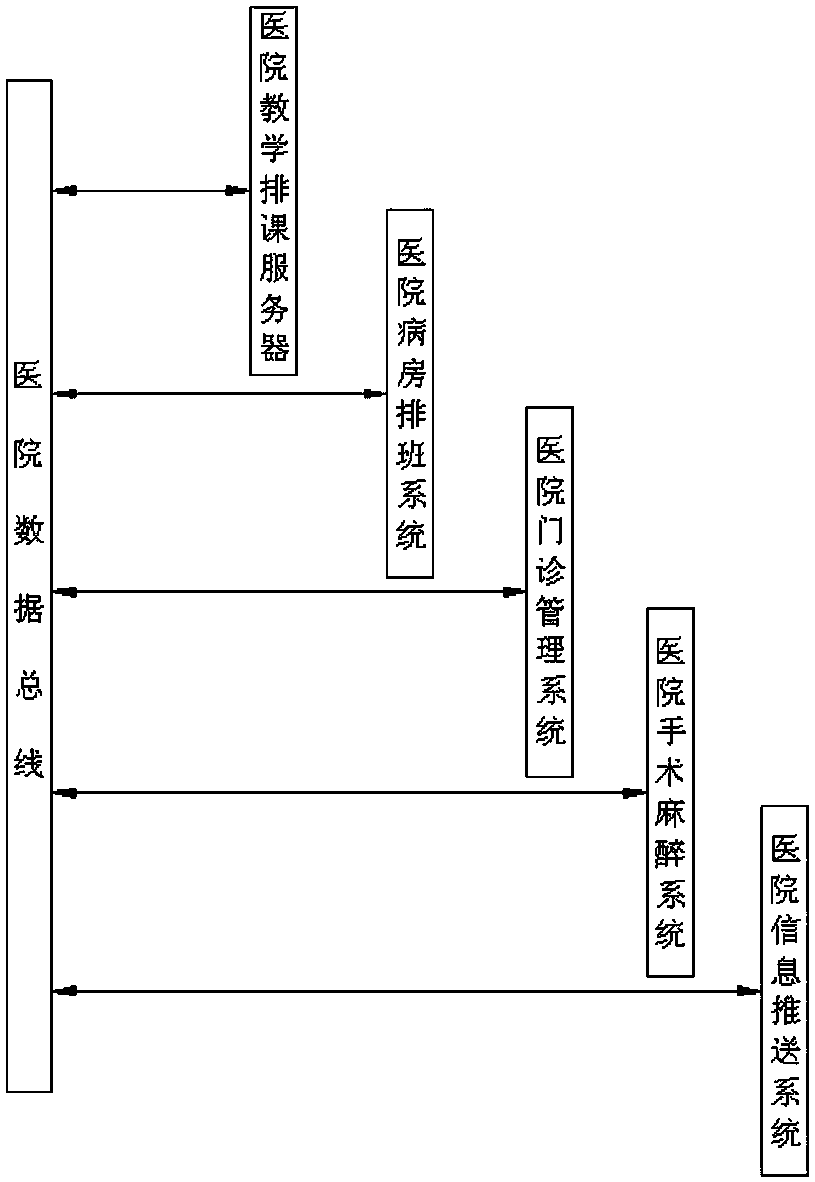

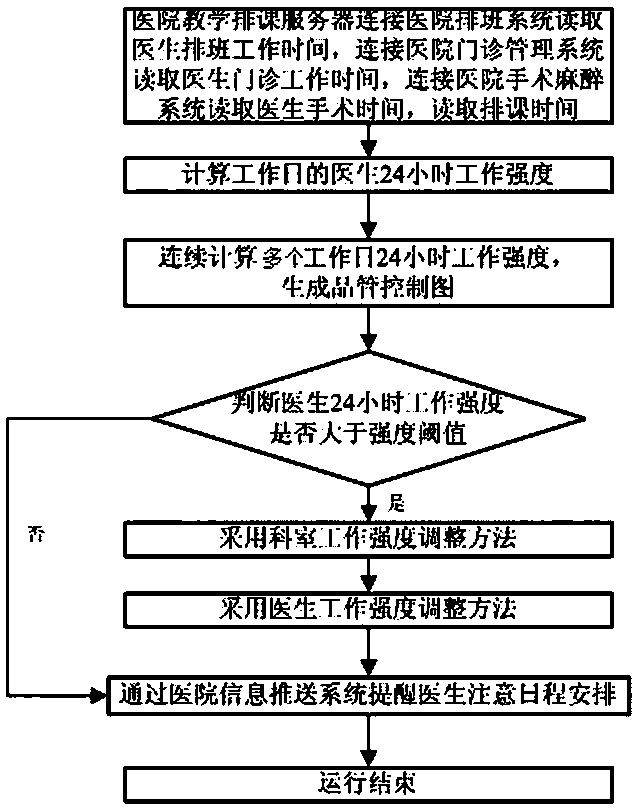

Hospital teaching course scheduling system and operation method thereof

ActiveCN107423916AWork intensity balance adjustmentReduce work intensityOffice automationResourcesWork periodMedical ward

The invention relates to a hospital teaching course scheduling system and an operation method thereof. A hospital teaching course scheduling server is connected to a hospital ward scheduling system, a hospital outpatient management system, a hospital surgical anesthesia system and a hospital information push system through a hospital data bus. The work duration of each doctor in ward, in outpatient department, in operation room and in classroom is calculated. The teaching time of each doctor is arranged reasonably according to the work strength of the doctor. The work strength information of doctors is displayed dynamically using a quality control chart, and is pushed in real time through the information push system. The relationship of outpatient service, surgery, night shift and teaching is conveniently and quickly coordinated in all aspects for doctors. The teaching and medical treatment time of doctors is arranged reasonably. The work strength of doctors is balanced and adjusted. The high-strength work time of doctors is reduced. Teaching accidents are avoided. The quality of teaching is improved. Different work links of doctors are evaluated quantitatively and accurately. The ability of doctors in teaching and clinical practice is assessed. Thus, doctors can always be in a best working or teaching state.

Owner:AFFILIATED HOSPITAL OF JIANGSU UNIV

Manufacture and application methods of hepatitis B surface antigen serum laboratory quality control material

InactiveCN106198988AQuality improvementImprove accuracyMaterial analysisMedicineContinual improvement process

The invention discloses manufacture and application methods of a hepatitis B surface antigen serum laboratory quality control material. The manufacture method comprises five steps as follows: acquisition and screening of raw materials, diluted serum manufacturing, preservation and monitoring of a standby quality control material, quality control, continuous improvement, etc. The application method comprises three steps as follows: storage, re-dissolution and application. The manufacture and application methods of the hepatitis B surface antigen serum laboratory quality control material are complete and clear. Due to the usage of a quality control chart of multiple impact factors, accuracy is high and control range is wide. By adoption of 31S quality control limit which is very sensitive to the system problem of unreasonable fundamental technological processes caused by insufficient technical capacity in the production process, the method is helpful for guaranteeing accuracy of the technological direction and determining good technological foundation and optimizing production technology.

Owner:CHANGSHA KINGMED MEDICAL DIAGNOSTICS INST

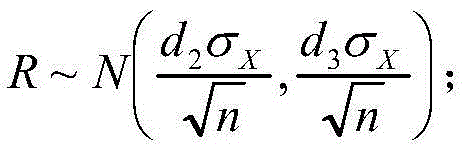

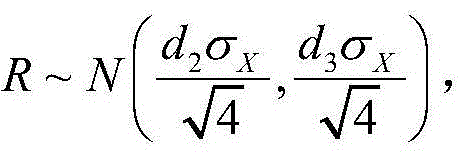

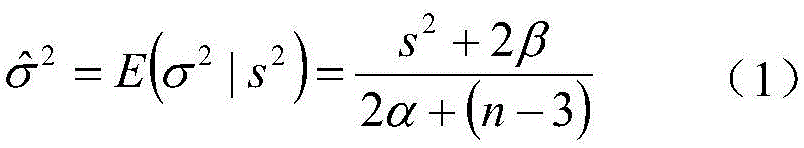

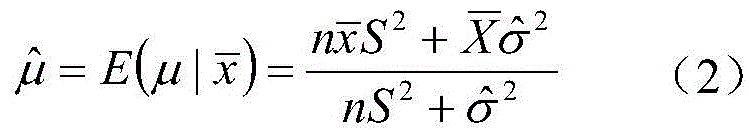

Small-sample optimal quality control method based on process capability

InactiveCN104133370AImprove quality requirementsImprove product qualityAdaptive controlSmall sampleProcess quality

The invention discloses a small-sample optimal quality control method based on a process capability. The method includes the following steps: 1. determining an objective function; 2. determining constraint conditions; 3. determining a concrete form of a model. Based on Bayes correction, the method studies a small sample which has utilization values to the correction and screens and discriminates the small sample through construction of a rapid judgment model and judges a process quality problem and thus under a condition that the process quality is known, a process quality control chart is designed to monitor a production process and the control chart is continued to be corrected according to a produced small sample and finally a better control effect can be achieved finally. At the same time, setting of a benchmark table also provides a reference for judgment of the process capability problem through use of the small sample.

Owner:方志耕

Calibration and quantification method for gas imaging camera

ActiveUS20150285704A1Television system detailsSensing radiation from gases/flamesTemperature differenceQuality control charts

The calibration / verification system and method for gas imaging infrared cameras standardizes the procedures to objectively and consistently check performance of gas imaging infrared cameras. This system includes a background board maintaining a uniform temperature, a target cell filled with a target compound and disposed in front of the background board, a reference cell filled with a reference compound and disposed in front of the background board, and an analyzer coupled to the camera that captures images of the gas cell and the reference cell. The analyzer compares the intensity difference and the temperature difference of rays passing through the target cell and reference cell to a reference relationship data of a quality control chart to determine whether the camera is in a working condition. The method is further extended to provide a quantitative measurement of a hydrocarbon plume from a gas imaging infrared camera.

Owner:PROVIDENCE PHOTONICS

Production and use methods of hepatitis B surface antigen serum indoor quality control product

InactiveCN106199020AQuality improvementLower the thresholdPreparing sample for investigationBiological testingSerum igeContinual improvement process

The invention discloses production and use methods of a hepatitis B surface antigen serum indoor quality control product. The production method includes the five steps of: raw material collection and screening, preparation of diluted serum, storage and monitoring of a standby quality control product, quality control, and continuous improvement; and the use method include the three steps of: storage, re-dissolving, and application. The production and use methods are complete and clear, are sensitive to random variables, and can find random problems and perform continuous improvement. The methods are low in difficult and has good operability since the most common Levery-Jennings quality control chart is employed; and the methods are very sensitive to unpredictable random problems that occur in a production process since a quality control limit of 13S is employed, so that the methods can be used for continuously improving and optimizing the production process in detail during production.

Owner:CHANGSHA KINGMED MEDICAL DIAGNOSTICS INST

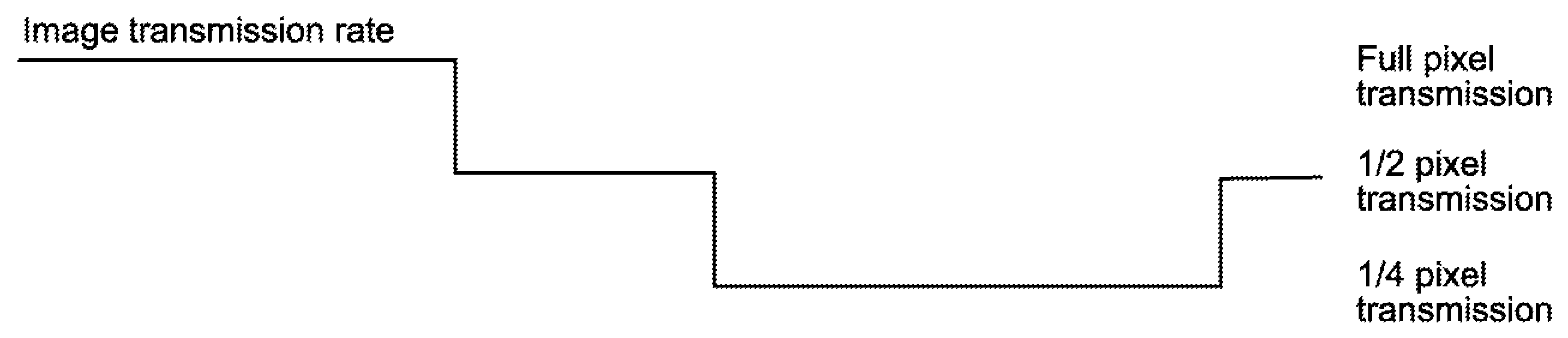

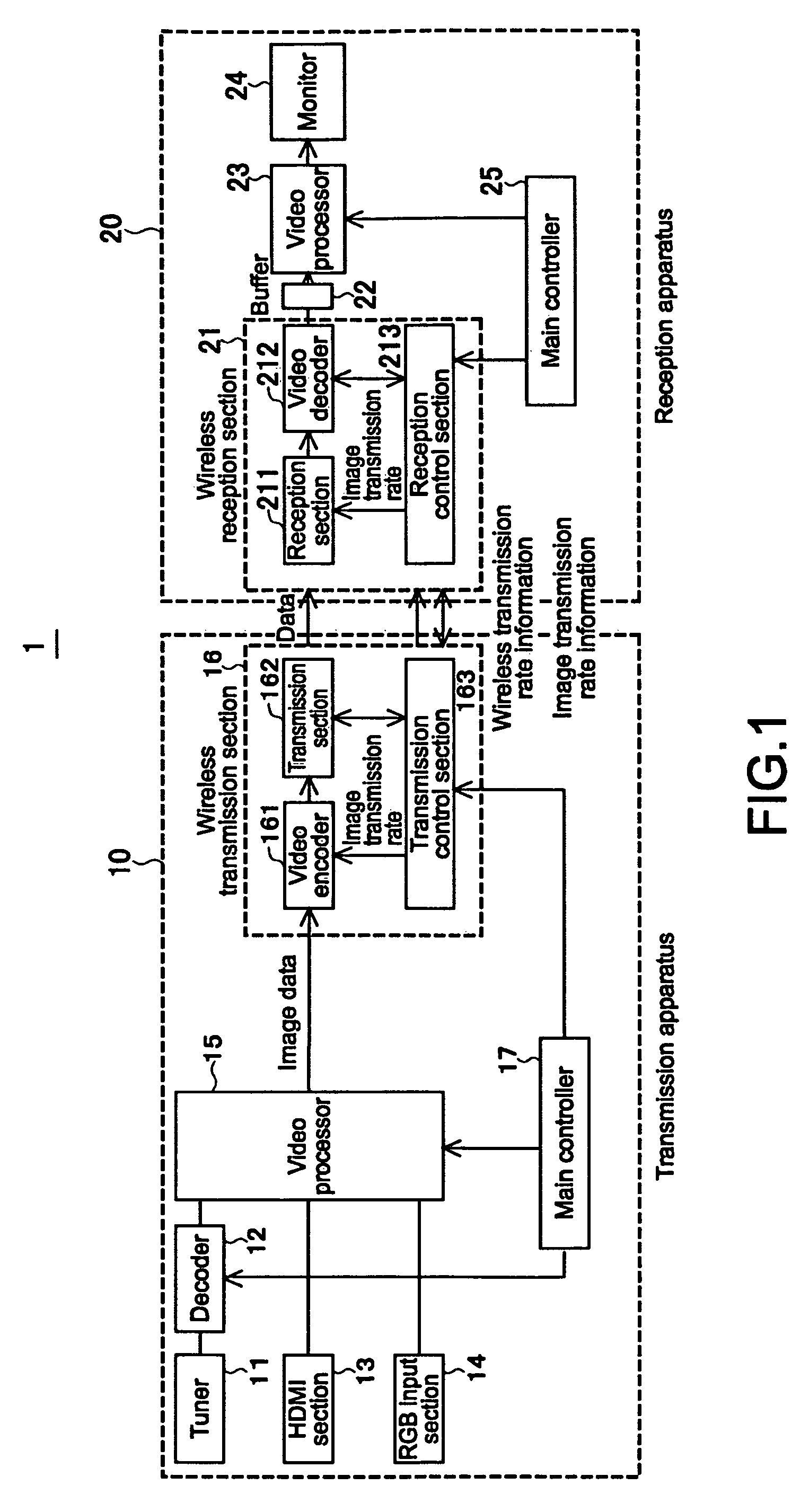

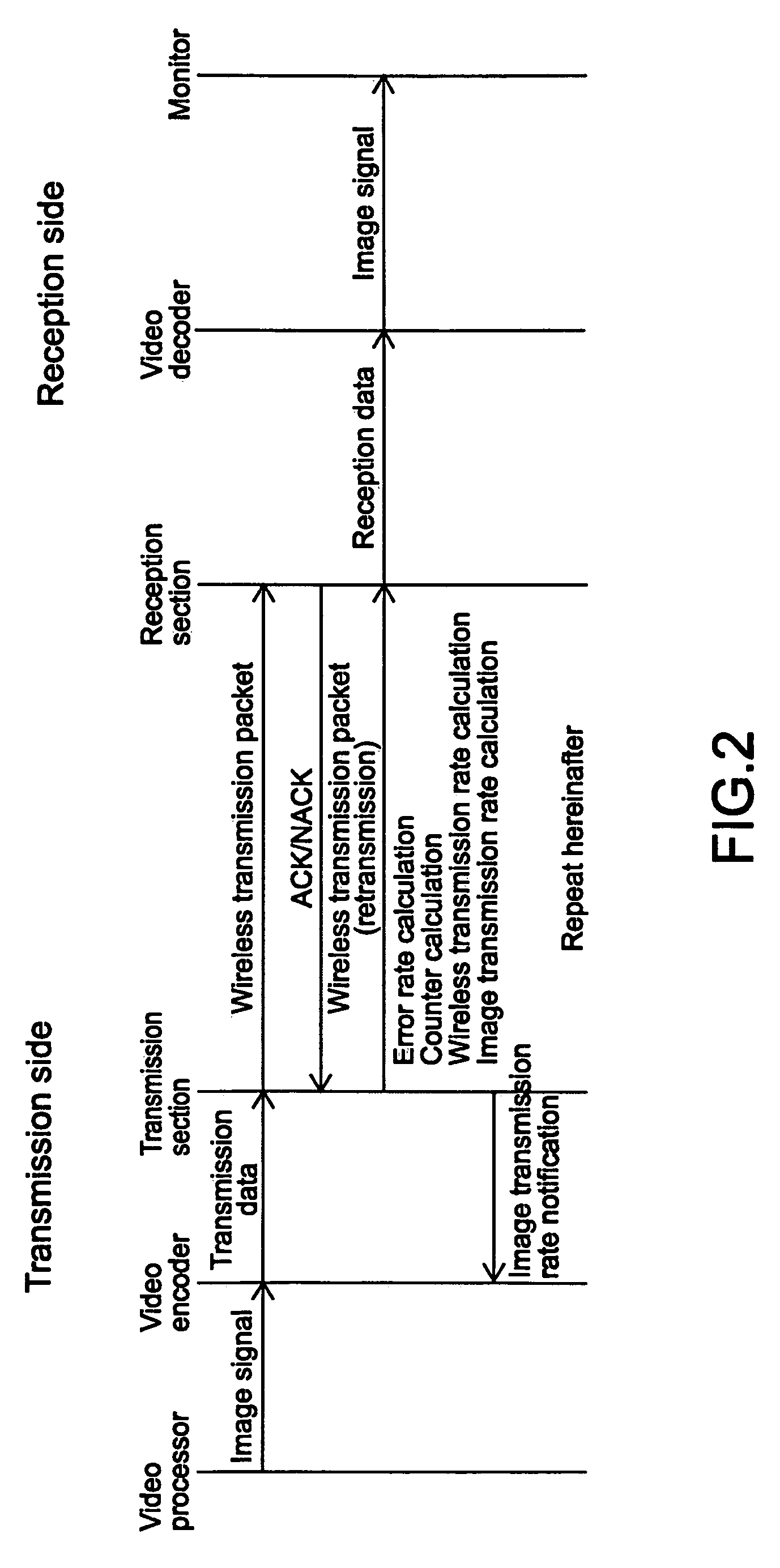

Apparatus and method to accommodate changes in communication quality

InactiveUS8902968B2Suppress flickerImprove subjective image qualityTelevision system detailsPulse modulation television signal transmissionCommunication qualityWireless transmission

A transmission apparatus which may include an image encoder, a transmitter, and a controller. The apparatus may encode image data, wirelessly transmit the encoded image data, detect a quality of a wireless transmission of the encoded image data and control an image transmission rate based on the detected quality. The image transmission rate may be controlled within a first response time when being lowered and controlled within a second response time longer than the first response time when being raised.

Owner:SONY CORP

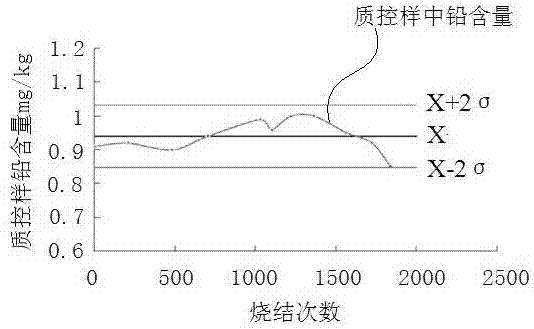

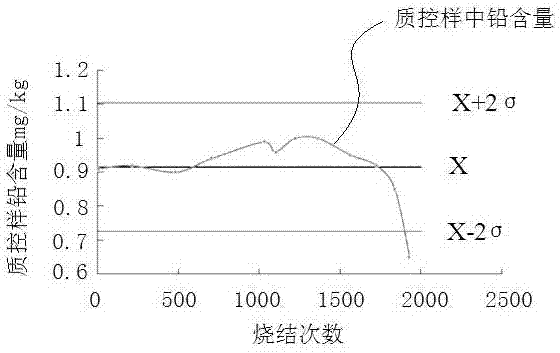

A method for judging the effective service life of graphite tubes in graphite furnace atomic absorption spectrometers

ActiveCN104730013BLess contentImprove economyColor/spectral properties measurementsEffective radiusQuality control

The invention discloses a method for judging the effective life of a graphite pipe in a graphite furnace atomic absorption spectrometer. The method takes pumpkin powder as a quality control sample, and comprises the steps of carrying out microwave digestion pretreatment on the pumpkin powder; segmenting the use period of the new graphite pipe into different stages according to the sintering times, accumulating the data of lead content of the quality control sample detected by adopting a graphite furnace atomic absorption spectrometry, and calculating the population mean X and the population standard deviation sigma of the lead content of the quality control sample; drawing a quality control chart by taking X as a center line and X + / -2 sigma as an upper warning line and a lower warning line; when the lead content of the quality control sample exceeds the warning lines X + / -2 sigma, recording the sintering times of the graphite pipe, which is the maximum sintering times of the graphite pipe, and confirming by using the certified reference material of lead. The method is reasonable in design, economical, practical and simple and convenient to operate, and is capable of lowering experimental cost and guaranteeing the accuracy of testing results.

Owner:INSPECTION & QUARANTINE TECH CENT OF GUANGDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

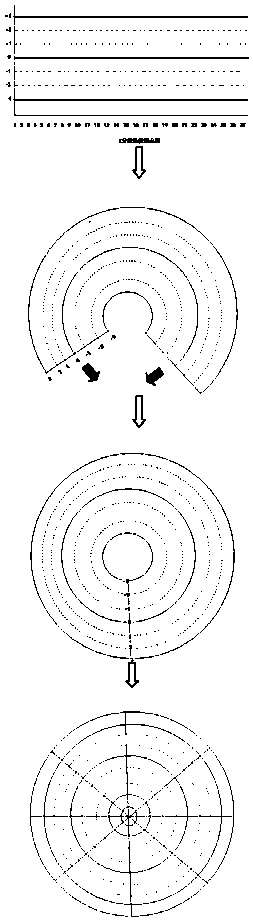

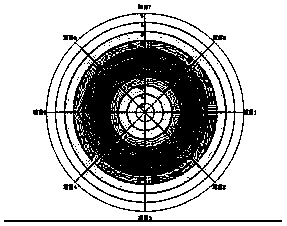

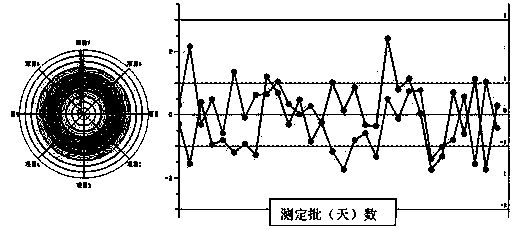

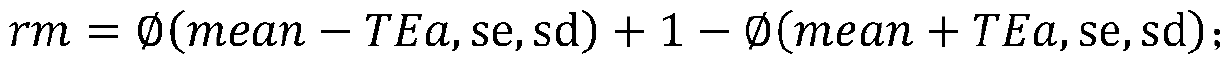

A quality control method based on a multivariate z-score quality control chart for laboratory diagnostics or industrial production

ActiveCN105045220BImprove quality control efficiencySimplify the management processTotal factory controlProgramme total factory controlState variableQuality control

The present invention proposes a quality control method based on a multivariate Z-score quality control chart, comprising: step a: obtaining multiple detection items detected by the detection equipment, that is, the Z-scores of multiple detection variables; step b: establishing concentric circles Multivariate Z score quality control chart; step c: mark the Z scores of the multiple detection variables on the multivariate Z score quality control chart respectively; and step d: mark by the Z score of the multiple detection variables The location obtains the quality control status of each of the detected variables. Through the present invention, the controlled or out-of-controlled state of multiple detected variables can be visually observed by using a multivariate Z score quality control chart. In addition, the control of system stability can be realized through the Zs variable Z score quality control chart.

Owner:上海脉联科技有限公司

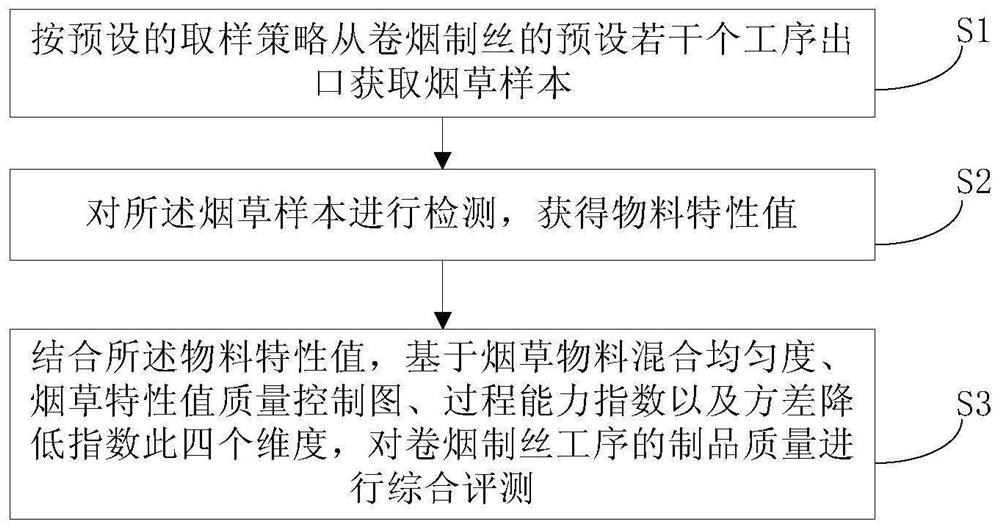

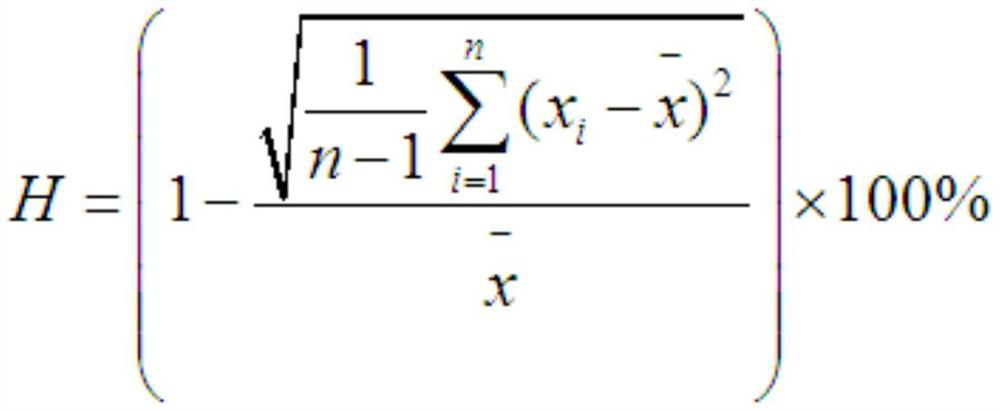

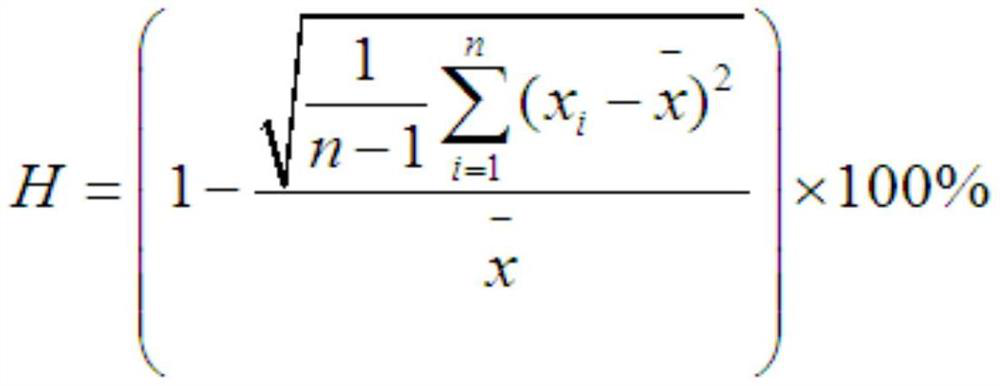

Material characteristic value-based multi-dimensional evaluation method for product quality in cigarette primary processing process

PendingCN114324764AComprehensive Multidimensional EvaluationObjective multidimensional evaluationCigarette manufactureMaterial analysisProcess engineeringQuality control charts

The invention discloses a multi-dimensional evaluation method for product quality in a cigarette primary processing process based on a material characteristic value, and the main design concept of the method is as follows: in combination with a specific process of a production workshop, a sample to be detected is obtained from an outlet of corresponding equipment, and a corresponding tobacco characteristic value is obtained; and establishing a comprehensive evaluation mechanism from four dimensions of a quality control chart, tobacco material mixing uniformity, a process capability index and a variance reduction index by utilizing the tobacco characteristic value. According to the method, comprehensive and objective multi-dimensional evaluation is carried out on the material mixing uniformity and quality stability in the cigarette cut tobacco making process in combination with a real production scene, and a reliable reference basis can be provided for the key process of cigarette cut tobacco making in the aspects of optimization, improvement and management and control of product quality stability.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Establishment method and application of quality control chart for brucellosis tube agglutination test

InactiveCN106053782BHigh precisionEasy to controlDisease diagnosisBiological testingQuality control chartsProcess control

The invention discloses a building method and application of a brucellosis tube agglutination test quality control chart. The building method and application has the advantages that the method applies the quality control chart to a tube agglutination test in an exploration and innovation manner, an optical density value is used as the control value to obtain an object controlled by the test, and a new statistical manner and reference are provided for the process control in the field of animal quarantine; in addition, during the application process of the quality control chart, the quality control chart can be regulated and optimized at any time along with the accumulation of test data so as to increase the precision and control power of the quality control chart.

Owner:BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU INSPECTION & QUARANTINE TECH CENT

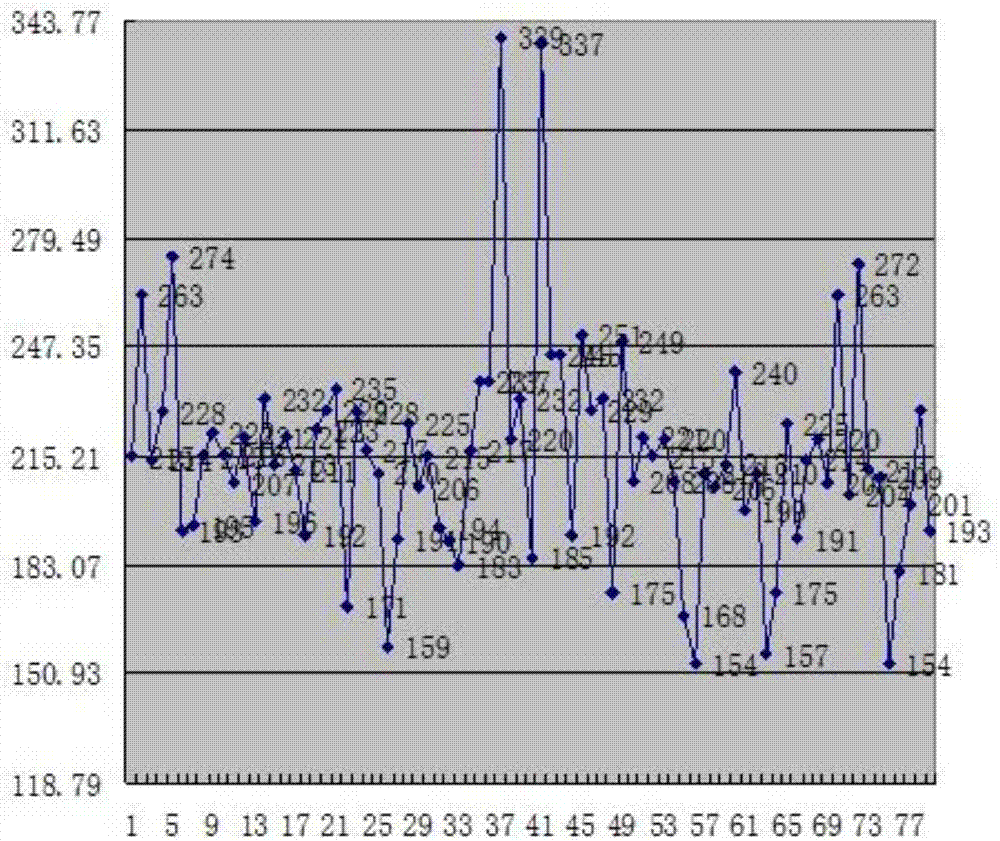

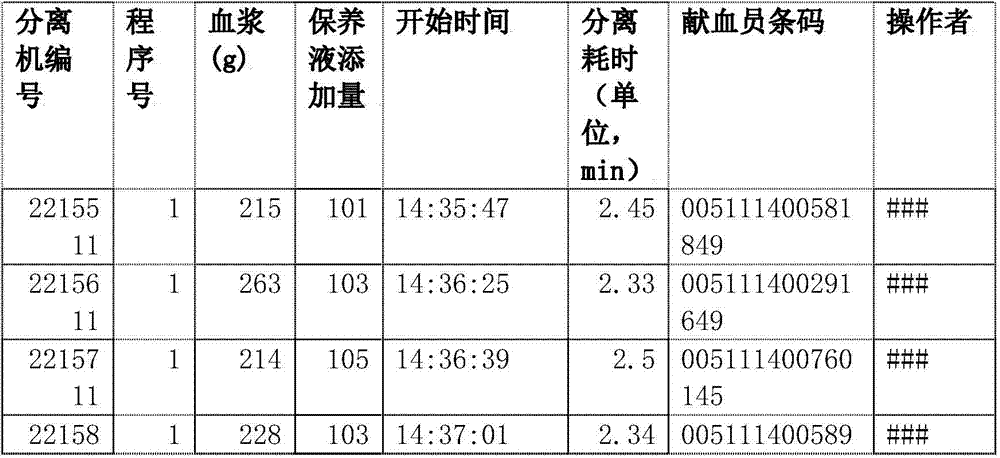

A method to ensure the quality of blood to meet the effect of blood transfusion - plasma quality control chart

ActiveCN105498000BSatisfy the effect of blood transfusionAccurate methodBlood transfusionBlood componentMedicine

Owner:廊坊市中心血站

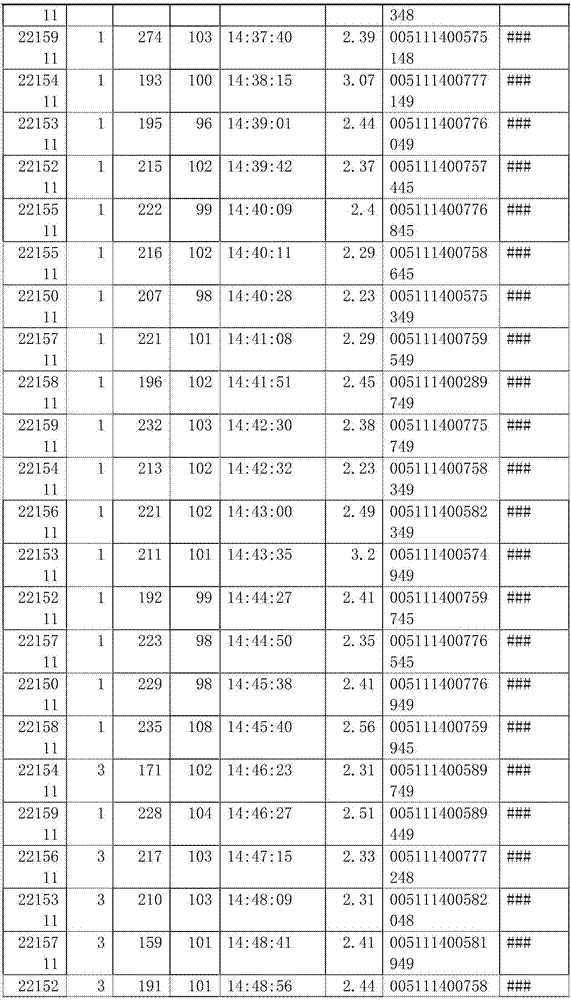

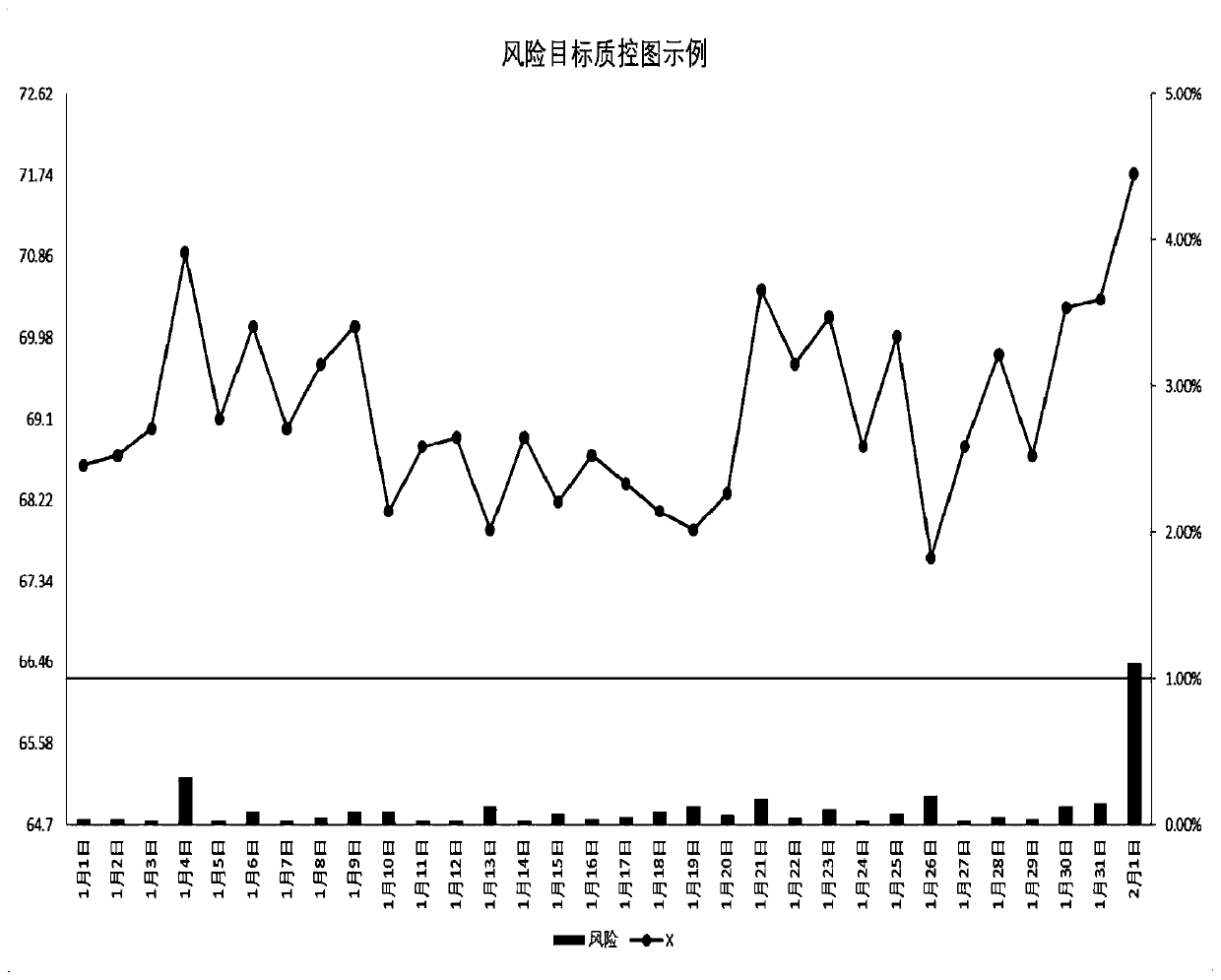

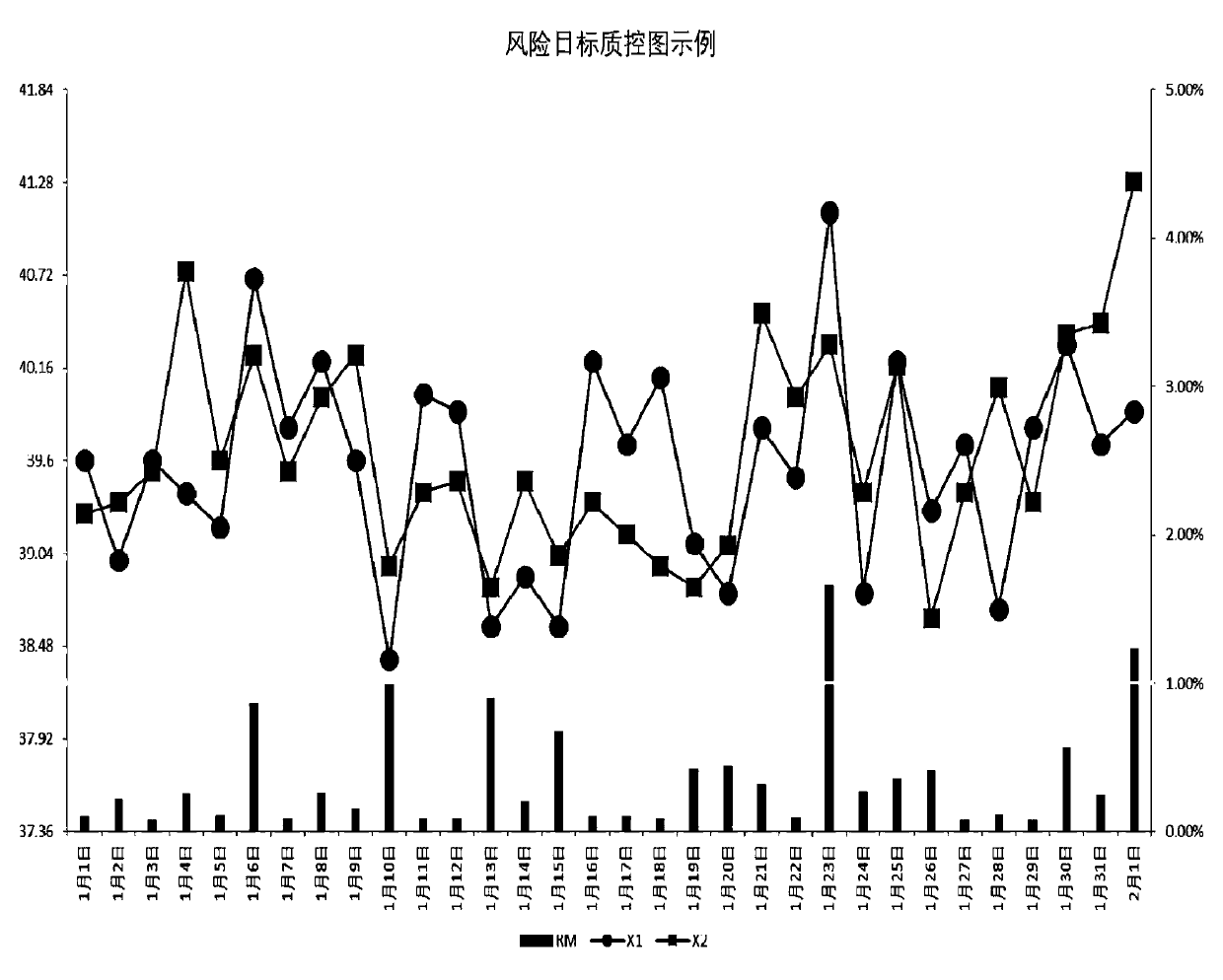

Laboratory risk target quality control chart drawing method

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

A Moving Point Estimation Method for Software Reliability Growth Model

ActiveCN103345443BJudgment criteriaPreliminary judgment is accurateSoftware testing/debuggingSoftware systemEstimation methods

The invention discloses an estimation method for mobile points of a software reliability growth model. The estimation method comprises the first step of drawing a quality control chart according to software system actual failure data, the second step of obtaining initial mobile points according to the quality control chart and a mobile point judging criterion, and the third step of obtaining the accurate positions of the mobile points by using a gradual adjustment method. According to the estimation method for the mobile points of the software reliability growth model, the mobile point judging criterion is provided, the preliminary judgment of the mobile points are more accurate, the number, obtained in an estimated mode, of the mobile points is accurate, and positional deviation is small. The estimation method for the mobile points of the software reliability growth model is a new mobile point estimation method, and the problem that the position estimation of the mobile points is not accurate is solved by using the gradual adjustment method on the basis that the number and the positions of the initial mobile points are obtained by using the quality control chart.

Owner:HARBIN ENG UNIV

A hospital teaching scheduling system and its operation method

ActiveCN107423916BWork intensity balance adjustmentReduce work intensityOffice automationResourcesQuality control chartsMedical treatment

The invention relates to a hospital teaching course scheduling system and an operation method thereof. A hospital teaching course scheduling server is connected to a hospital ward scheduling system, a hospital outpatient management system, a hospital surgical anesthesia system and a hospital information push system through a hospital data bus. The work duration of each doctor in ward, in outpatient department, in operation room and in classroom is calculated. The teaching time of each doctor is arranged reasonably according to the work strength of the doctor. The work strength information of doctors is displayed dynamically using a quality control chart, and is pushed in real time through the information push system. The relationship of outpatient service, surgery, night shift and teaching is conveniently and quickly coordinated in all aspects for doctors. The teaching and medical treatment time of doctors is arranged reasonably. The work strength of doctors is balanced and adjusted. The high-strength work time of doctors is reduced. Teaching accidents are avoided. The quality of teaching is improved. Different work links of doctors are evaluated quantitatively and accurately. The ability of doctors in teaching and clinical practice is assessed. Thus, doctors can always be in a best working or teaching state.

Owner:AFFILIATED HOSPITAL OF JIANGSU UNIV

An Optimal Quality Control Method for Small Samples Based on Process Capability

InactiveCN104133370BImprove quality requirementsImprove product qualityAdaptive controlProcess qualitySmall sample

The invention discloses a small-sample optimal quality control method based on a process capability. The method includes the following steps: 1. determining an objective function; 2. determining constraint conditions; 3. determining a concrete form of a model. Based on Bayes correction, the method studies a small sample which has utilization values to the correction and screens and discriminates the small sample through construction of a rapid judgment model and judges a process quality problem and thus under a condition that the process quality is known, a process quality control chart is designed to monitor a production process and the control chart is continued to be corrected according to a produced small sample and finally a better control effect can be achieved finally. At the same time, setting of a benchmark table also provides a reference for judgment of the process capability problem through use of the small sample.

Owner:方志耕

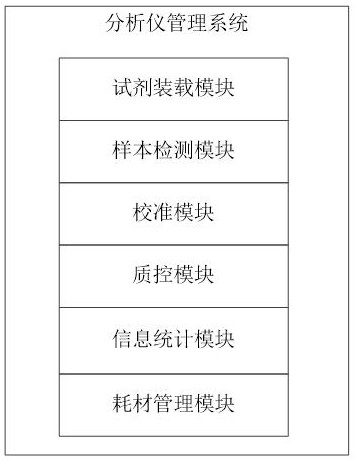

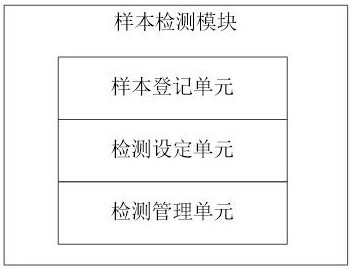

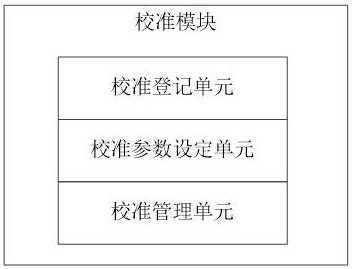

Full-automatic chemiluminescence immunoassay analyzer management system

PendingCN114200151ATimely replacementTimely supplementChemiluminescene/bioluminescenceBiological testingComputer hardwareData information

The invention belongs to the technical field of information management, and provides a full-automatic chemiluminescence immunoassay analyzer management system, which comprises a reagent loading module used for scanning an RFID card on a reagent bottle, reading data information of the reagent bottle and displaying the data information on a preset interface; the sample detection module is used for acquiring data information and position information of the sample in a preset mode and performing detection management on the acquired sample according to a preset detection item; the calibration module is used for performing calibration detection on a preset detection item according to a preset calibration parameter; and the quality control module is used for performing out-of-control analysis on the quality control data according to a preset quality control method. The method has the advantages that a plurality of quality control rules can be selectively combined to form a corresponding quality control method, and the quality control data is subjected to failure analysis, so that the accuracy of a detection result is ensured; and quality control data are integrated to form a quality control chart, and alarm information is sent out in time when the quality control chart is out of control, so that the work of the analyzer can be stopped in time.

Owner:宁波海尔施智造有限公司

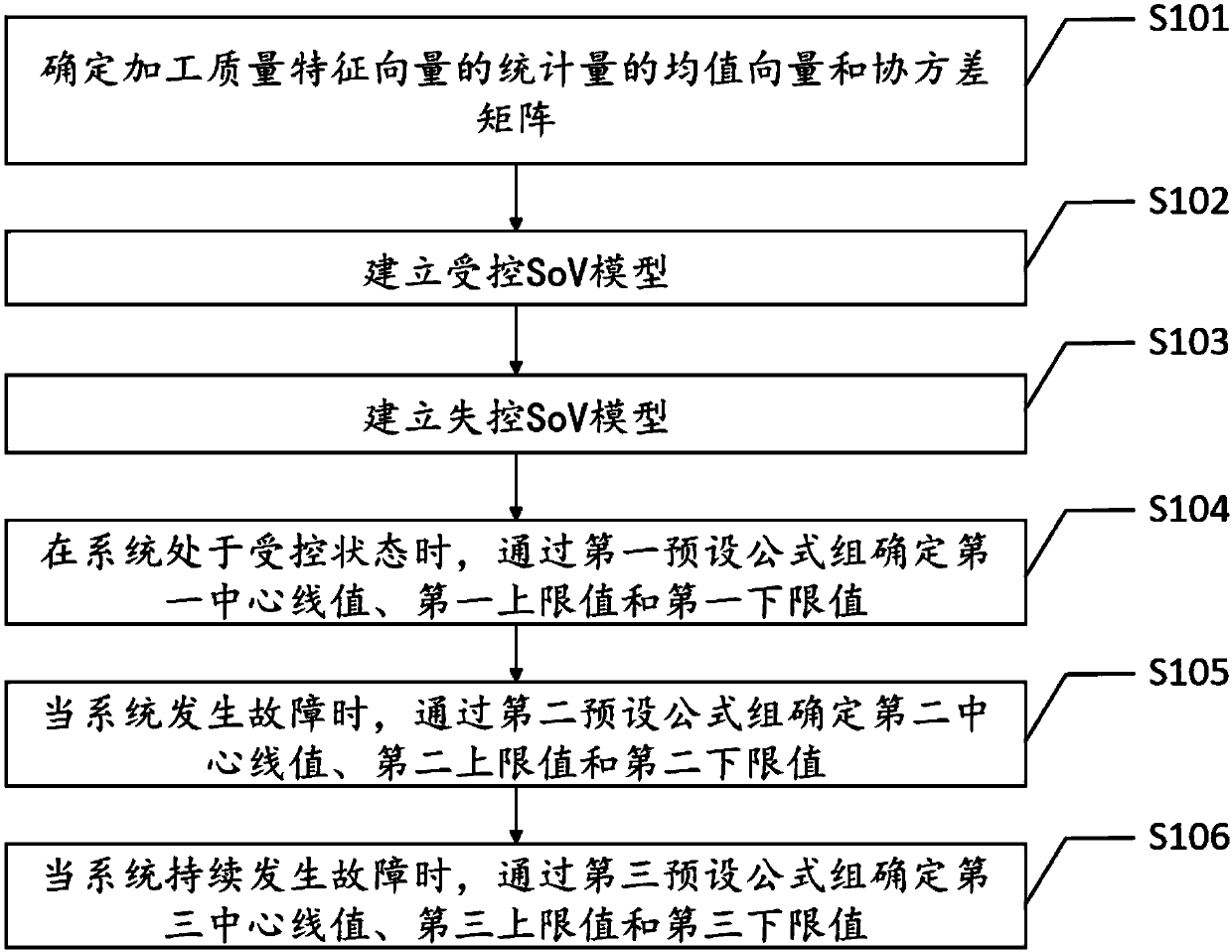

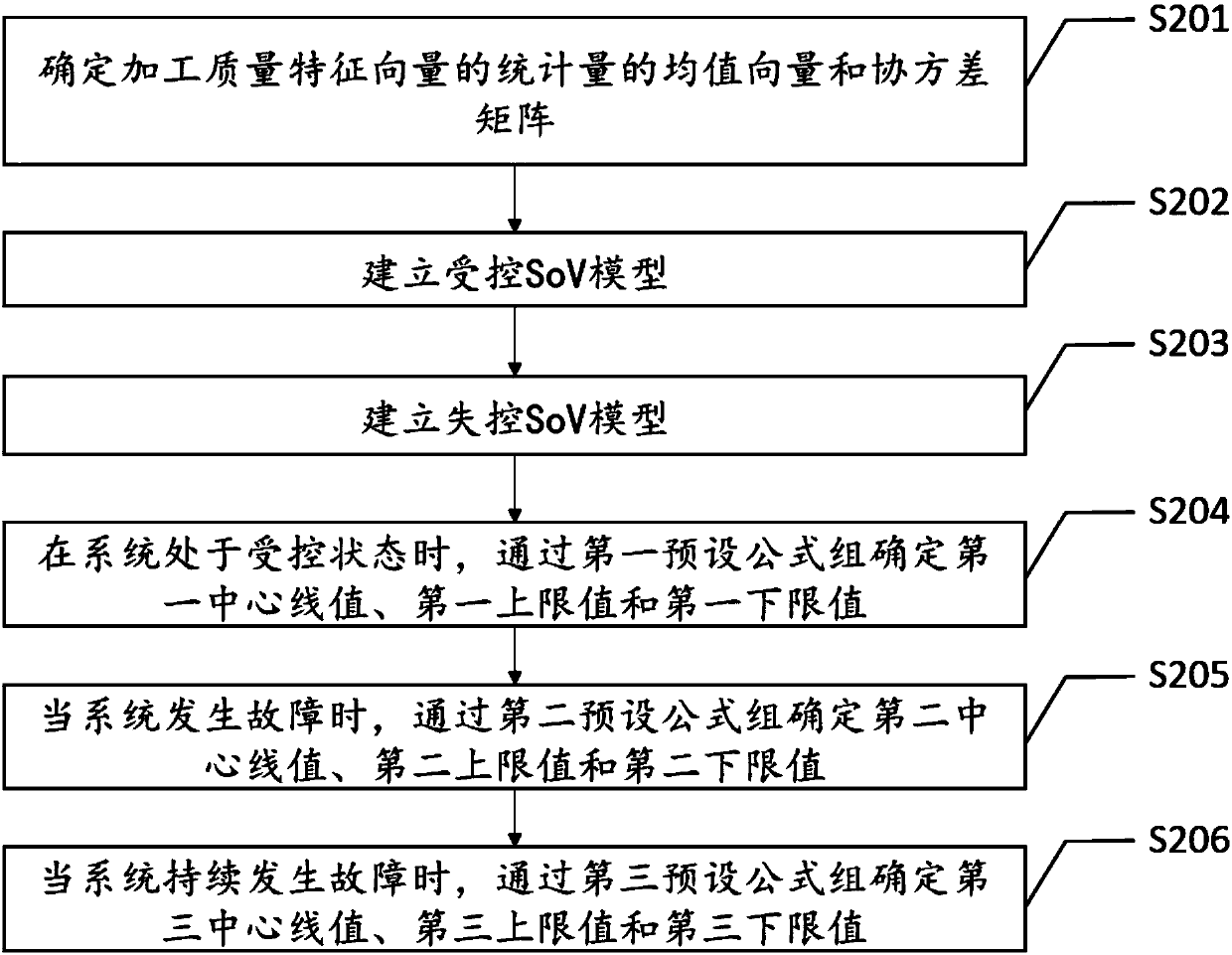

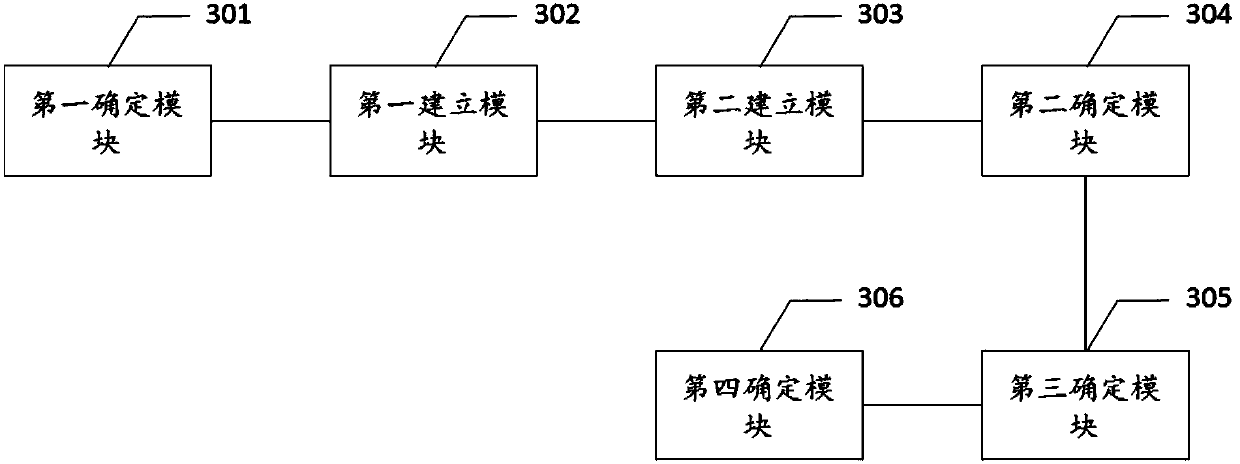

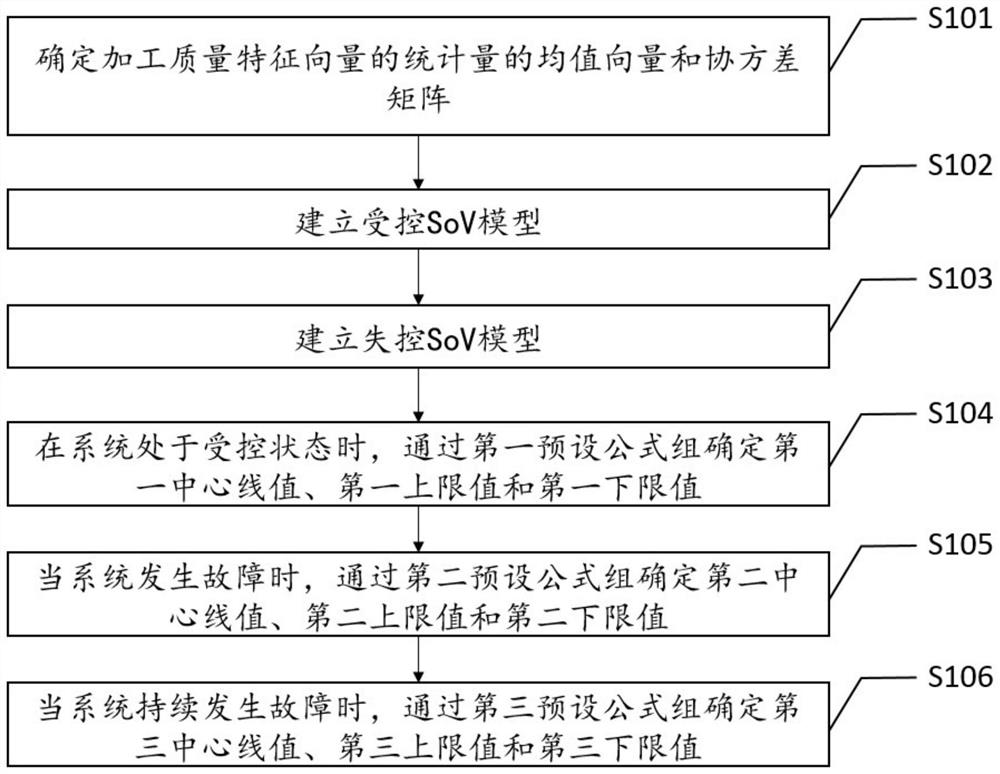

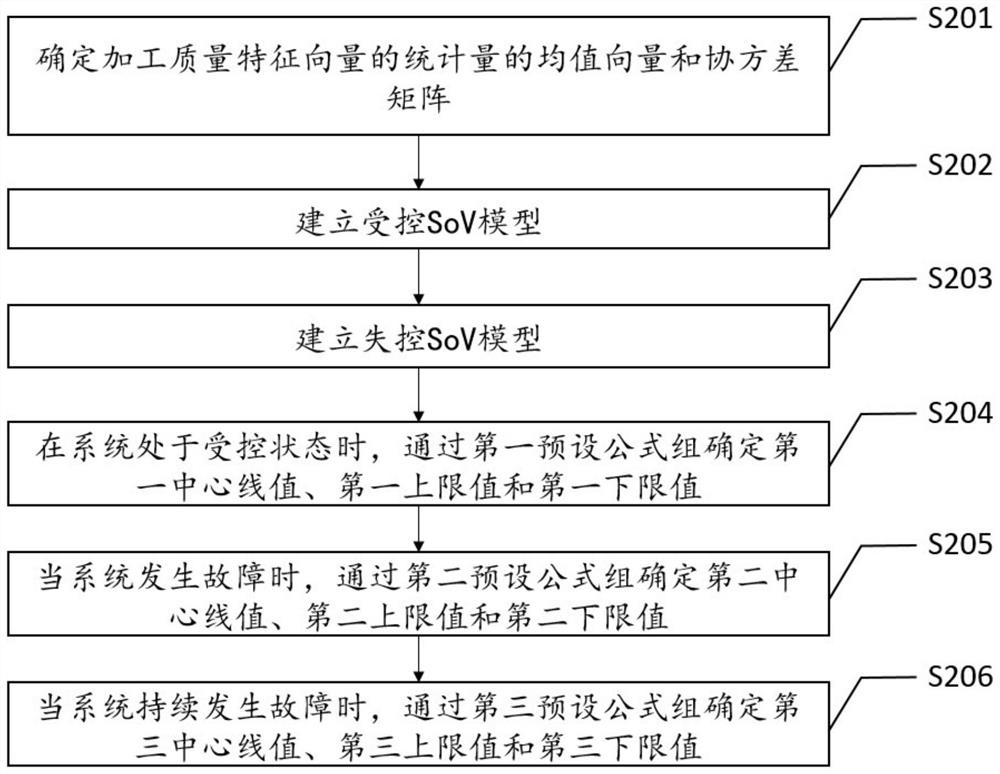

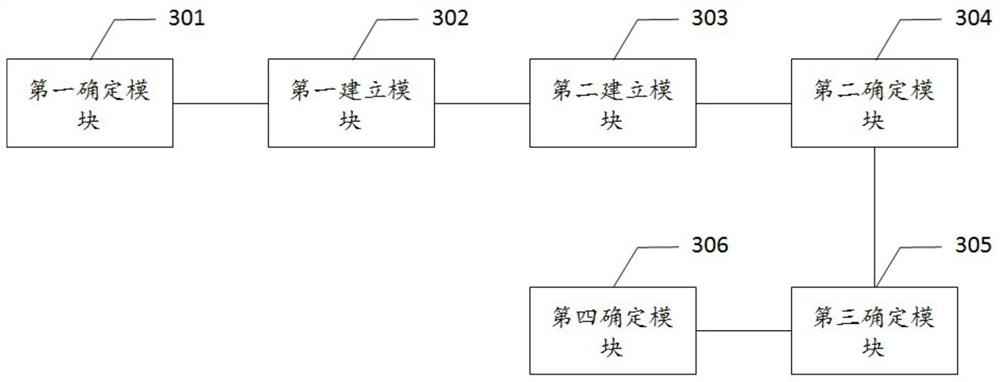

R2R manufacturing system fault coverage determination method and device

ActiveCN108427388ATotal factory controlProgramme total factory controlFault coverageProcess deviations

The invention discloses an R2R manufacturing system fault coverage determination method and device. The method comprises the steps that on the basis of correlation analysis among various stations of aflexible material (Roll to Roll, R2R) manufacturing system, physical analysis and a data driving method are combined to establish a relational expression describing multi-station process deviation and product final quality, a model of a variation stream (stream of variation, SoV) in controlled and uncontrolled states of the manufacturing system is established, a corresponding quality control chart used for monitoring autocorrelation data is established for product quality characteristic variables, the problem of high false alarm rate in fault determination methods of an existing single-factorcontrol chart, multi-factor control chart, a regression adjustment control chart and the like when a multi-station system is monitored is solved, especially when the process data has autocorrelation,and the technical problem that the abnormal failure in the manufacturing process cannot be monitored by adopting a conventional control chart under an independence assumption is solved.

Owner:GUANGDONG UNIV OF TECH +1

Method and device for determining fault range of r2r manufacturing system

ActiveCN108427388BTotal factory controlProgramme total factory controlFault coverageRegression adjustment

The invention discloses an R2R manufacturing system fault coverage determination method and device. The method comprises the steps that on the basis of correlation analysis among various stations of aflexible material (Roll to Roll, R2R) manufacturing system, physical analysis and a data driving method are combined to establish a relational expression describing multi-station process deviation and product final quality, a model of a variation stream (stream of variation, SoV) in controlled and uncontrolled states of the manufacturing system is established, a corresponding quality control chart used for monitoring autocorrelation data is established for product quality characteristic variables, the problem of high false alarm rate in fault determination methods of an existing single-factorcontrol chart, multi-factor control chart, a regression adjustment control chart and the like when a multi-station system is monitored is solved, especially when the process data has autocorrelation,and the technical problem that the abnormal failure in the manufacturing process cannot be monitored by adopting a conventional control chart under an independence assumption is solved.

Owner:GUANGDONG UNIV OF TECH +1

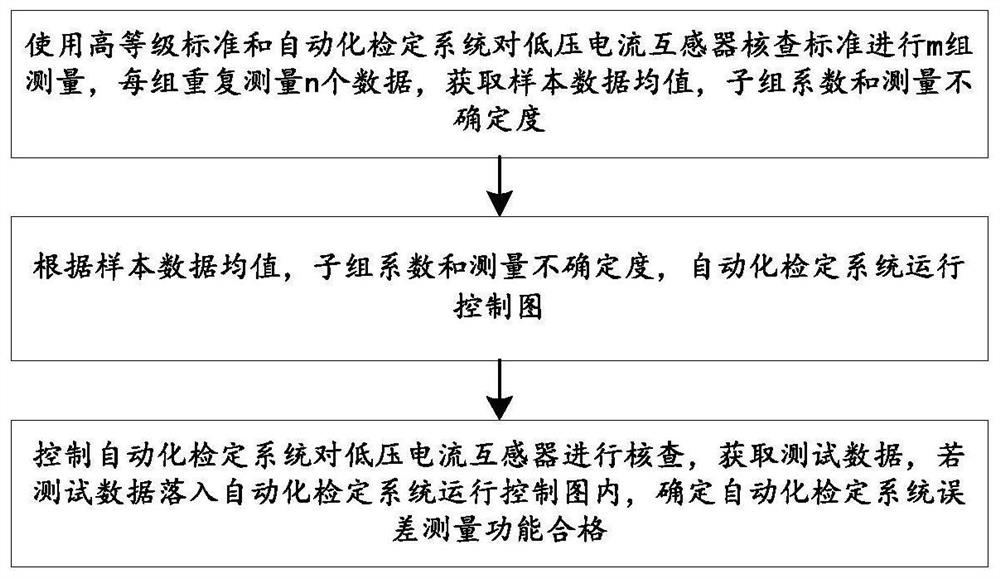

A method and system for determining the error measurement function of an automated verification system

The invention discloses a method and system for determining the error measurement function of an automatic verification system, belonging to the technical field of electric measurement. The method of the present invention comprises: using a high-level standard and an automatic verification system to carry out m groups of measurements on the low-voltage current transformer inspection standards, each group repeatedly measures n data, and obtains the mean value of sample data, subgroup coefficients and measurement uncertainty; according to the sample data Mean value, subgroup coefficient and measurement uncertainty, automatic verification system operation control chart; control the automatic verification system to check the low-voltage current transformer, obtain test data, if the test data falls into the automatic verification system operation control chart, determine the automatic verification The system error measurement function is qualified. The invention utilizes the quality control chart of the verification standard and the control chart of the running state of the assembly line to visually record whether the measurement process of the assembly line is in the state of statistical control, so that the running state of the automatic verification system is always under controlled supervision.

Owner:STATE GRID HUBEI MARKETING SERVICE CENT (MEASUREMENT CENT) +2

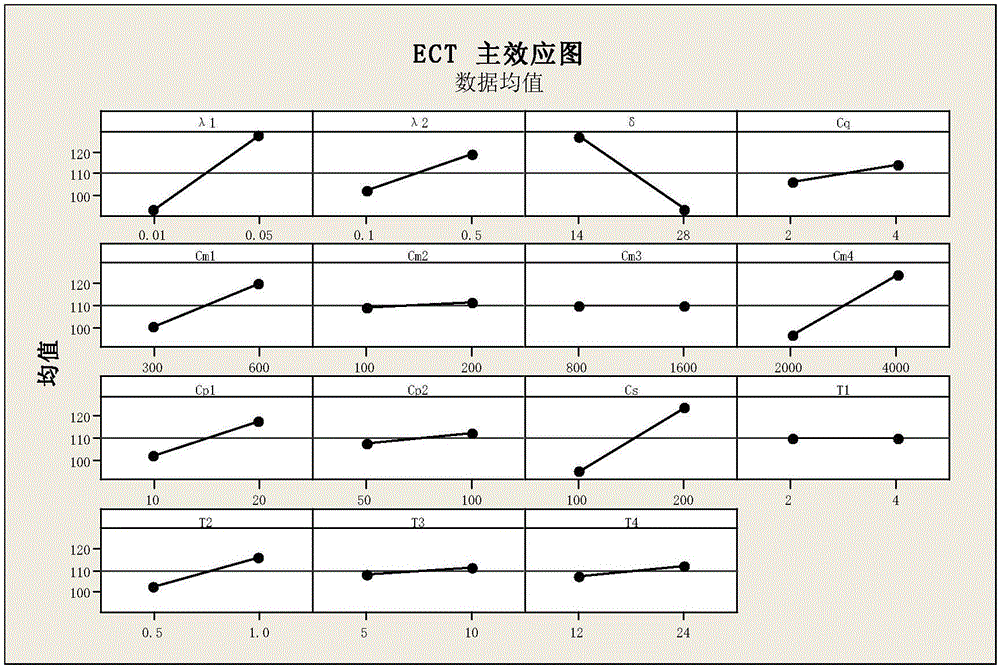

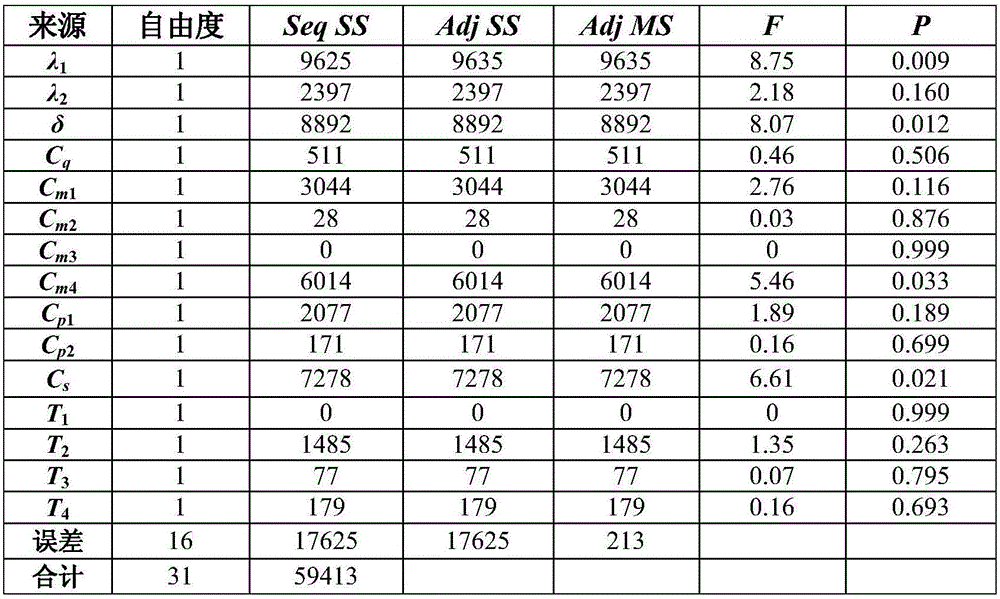

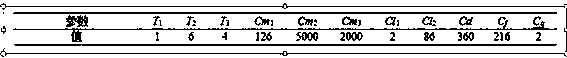

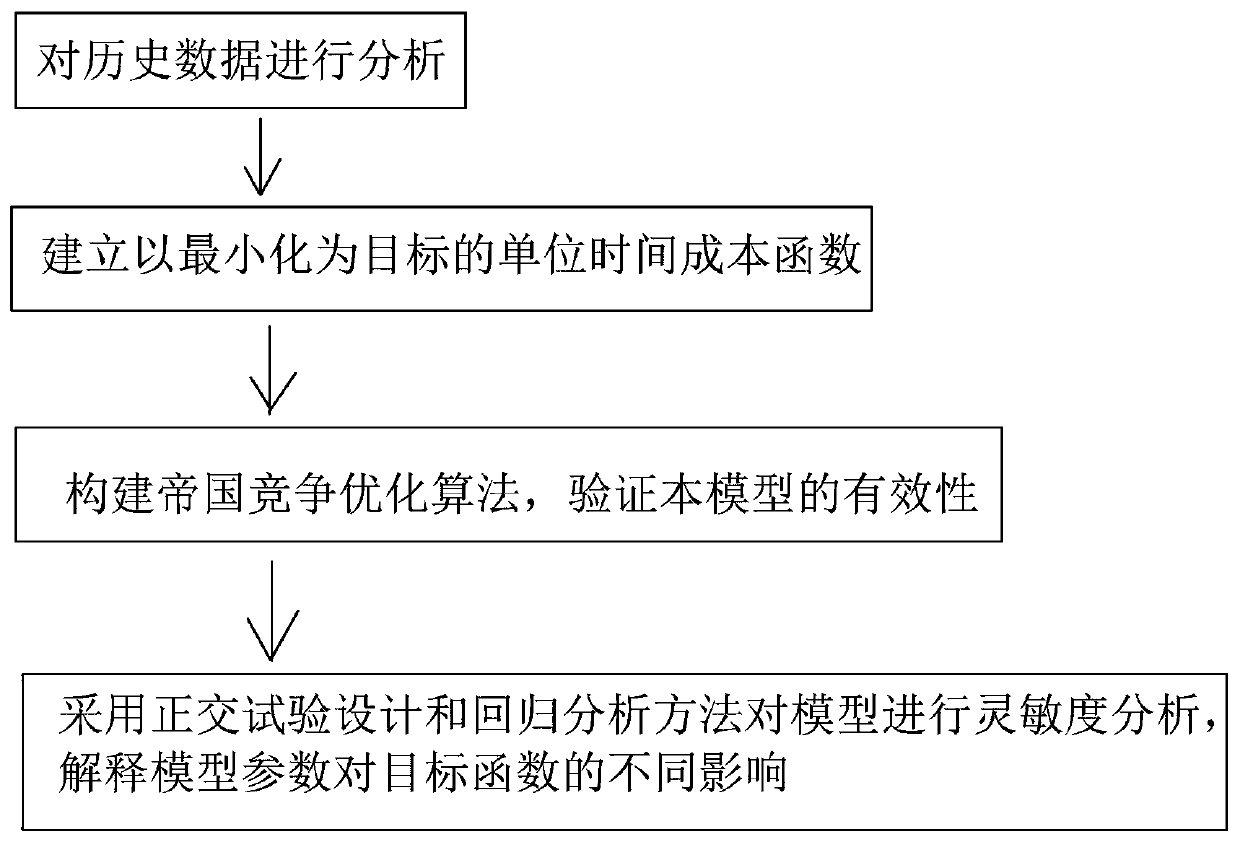

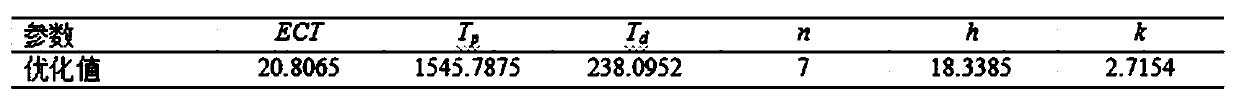

Improved preventive maintenance and mean value control chart combined economic optimization method

The invention relates to an improved preventive maintenance and mean value control chart combined economic optimization method, and provides an improved process quality control chart and preventive maintenance combined design optimization method on the basis of considering that the early failure probability of equipment is low, and the method comprises the following steps: 1, analyzing historicaldata; step 2, establishing a unit time cost function ECT by taking minimization as a target according to the abnormal condition of the system; 3, constructing an empire competition optimization algorithm according to the model, and verifying the effectiveness of the model by adopting a Matlab language and combining the production process of a certain mold manufacturing enterprise; 4, performing sensitivity analysis on the model by adopting an orthogonal test design and regression analysis method, and explaining different influences of model parameters on a target function. Due to the fact thata control chart detection point is delayed to a certain preset time point, for a system with a relatively low early hazard rate in a production process, and compared with a system model which initially implements control chart monitoring in system operation, the model of the invention can obtain better economic performance.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

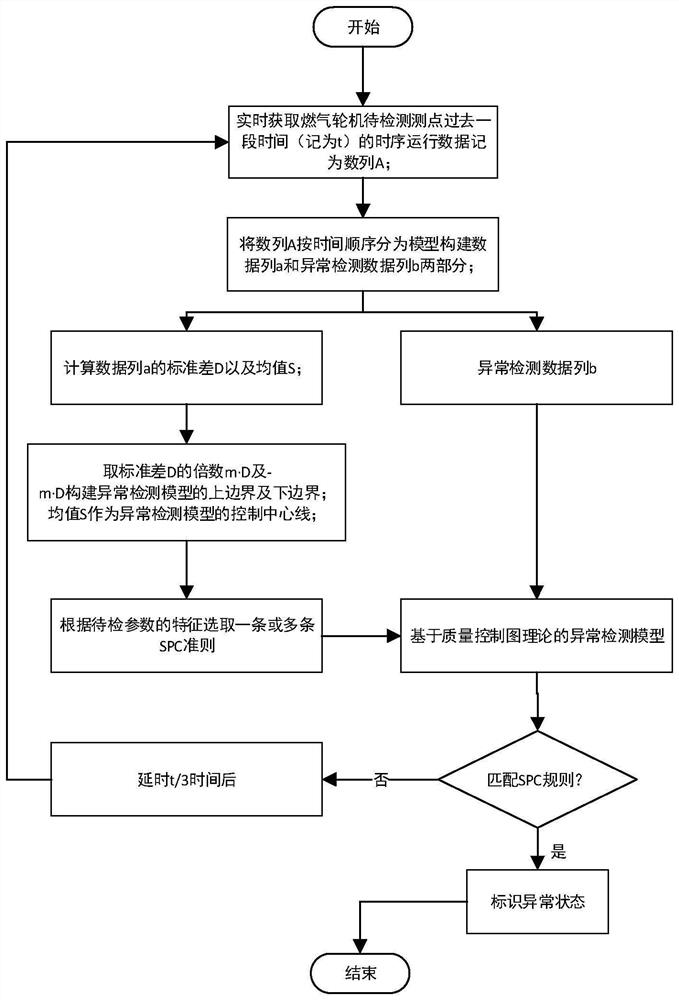

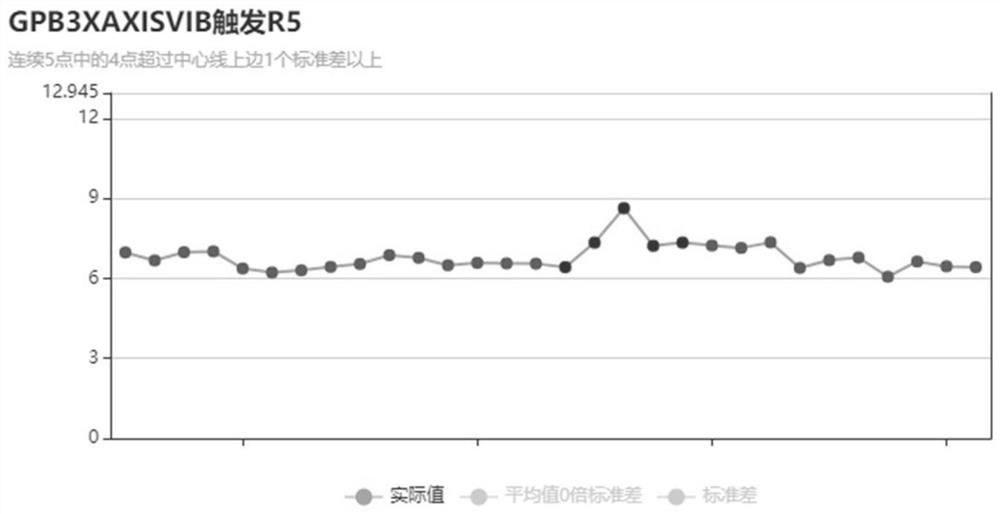

Gas turbine anomaly detection method based on quality control chart theory

ActiveCN114239708ASimple Anomaly DetectionAccurate Anomaly DetectionCharacter and pattern recognitionAnomaly detectionModel building

The invention aims to provide a gas turbine anomaly detection method based on a quality control chart theory. The gas turbine anomaly detection method comprises the following steps: acquiring time sequence operation data of time t of a to-be-detected measurement point of a gas turbine in real time, and dividing the time sequence operation data into a model construction data column a and an anomaly detection data column b according to a time sequence; constructing an upper boundary and a lower boundary of the anomaly detection model through a method of giving a standard deviation multiple m of a model construction data column a, and calculating a mean value of the model construction data column a as a control center line of the anomaly detection model; selecting one or more corresponding detection rules based on a quality control chart theory according to gas turbine operation experience and to-be-detected data point characteristics; and detecting data of an abnormal detection data column b by using the model, if the data accords with the description of the detection model, indicating that the data of the data point is abnormal, otherwise, repeating the process after t / 3 time so as to realize real-time iterative anomaly detection. According to the invention, health monitoring and fault pre-judgment can be effectively carried out on mass highly complex system information data of the gas turbine.

Owner:中国船舶重工集团公司第七0三研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com