Assembly line product information collection method and collection device

A technology of product information and collection device, applied in the direction of comprehensive factory control, instrumentation, comprehensive factory control, etc., can solve problems such as large number of defects, increased rework cost, and reduced production efficiency, so as to improve information collection efficiency, reduce process cost, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

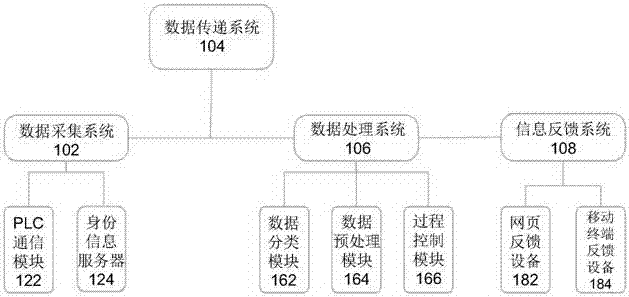

[0041] refer to figure 1 as shown, figure 1 A structural block diagram of an assembly line product information collection device according to an embodiment of the present invention is disclosed. As shown in the figure, the assembly line product information collection device includes: a data collection system 102 , a data transmission system 104 , a data processing system 106 and an information feedback system 108 . The data collection system 102 collects the identity information of the assembly line products. The data transmission system 104 exchanges data with each station on the assembly line, and each station on the assembly line collects on-site data. The data processing system 106 obtains the on-site data collected by each station on the assembly line through the data transmission system 104, processes the on-site data, and generates result data. The result data includes establishing and optimizing a quality control chart based on the on-site data. The information feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com