Bent short wire end stripping device

A curved, short wire technology, applied in the field of curved short wire end peeling devices, can solve the problems of wasting wire ends, bending or twisting, wasting labor, etc., and achieves the effects of saving time, ingenious design, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments of the accompanying drawings.

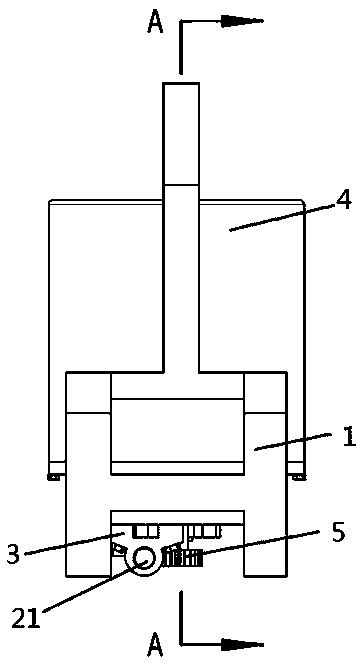

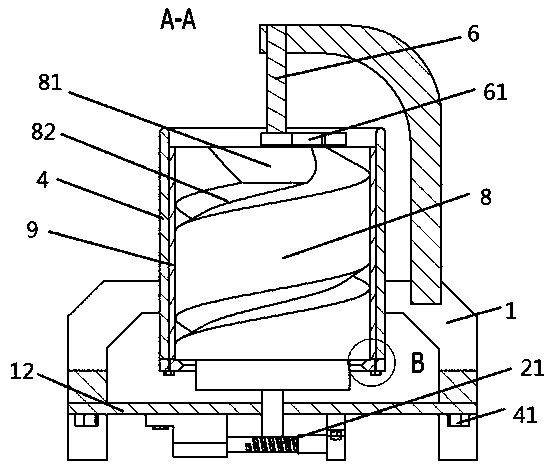

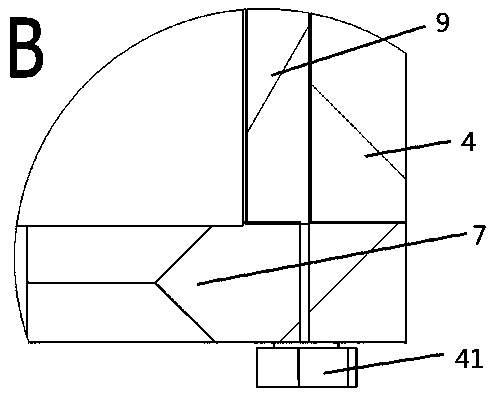

[0016] Such as Figure 1-5 As shown, a kind of curved short wire end peeling device of the present invention is characterized in that: the main body is the fixed frame 1, the motor 2, the fixed barrel 4 and the rotating column 8; the upper end of the fixed frame 1 is provided with a rotatable The fixed shaft 6 is provided with a fixed barrel 4 fixed by welding in the middle, and the inner wall of the fixed barrel 4 is provided with a rubber ring 9 fixed by glue; the bottom of the fixed barrel 4 is provided with an annular blade 7 fixed by a screw 41; The bottom of the fixed frame 1 is provided with a connecting plate 12 and a motor 2 fixed on the bottom of the connecting plate 12, and the front end of the motor 2 is provided with a screw rod 21 and a support angle seat 3 p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap