Spreader unit for a drum brake, comprising wear travel adjustment, and drum brake

一种鼓式制动器、驱动单元的技术,应用在机械驱动鼓式制动器、制动器的部件、松弛调节器等方向,能够解决降低制动器刚度和响应速度、限制等问题,达到补偿不均匀的贴靠、高功能可靠性、降低故障敏感性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

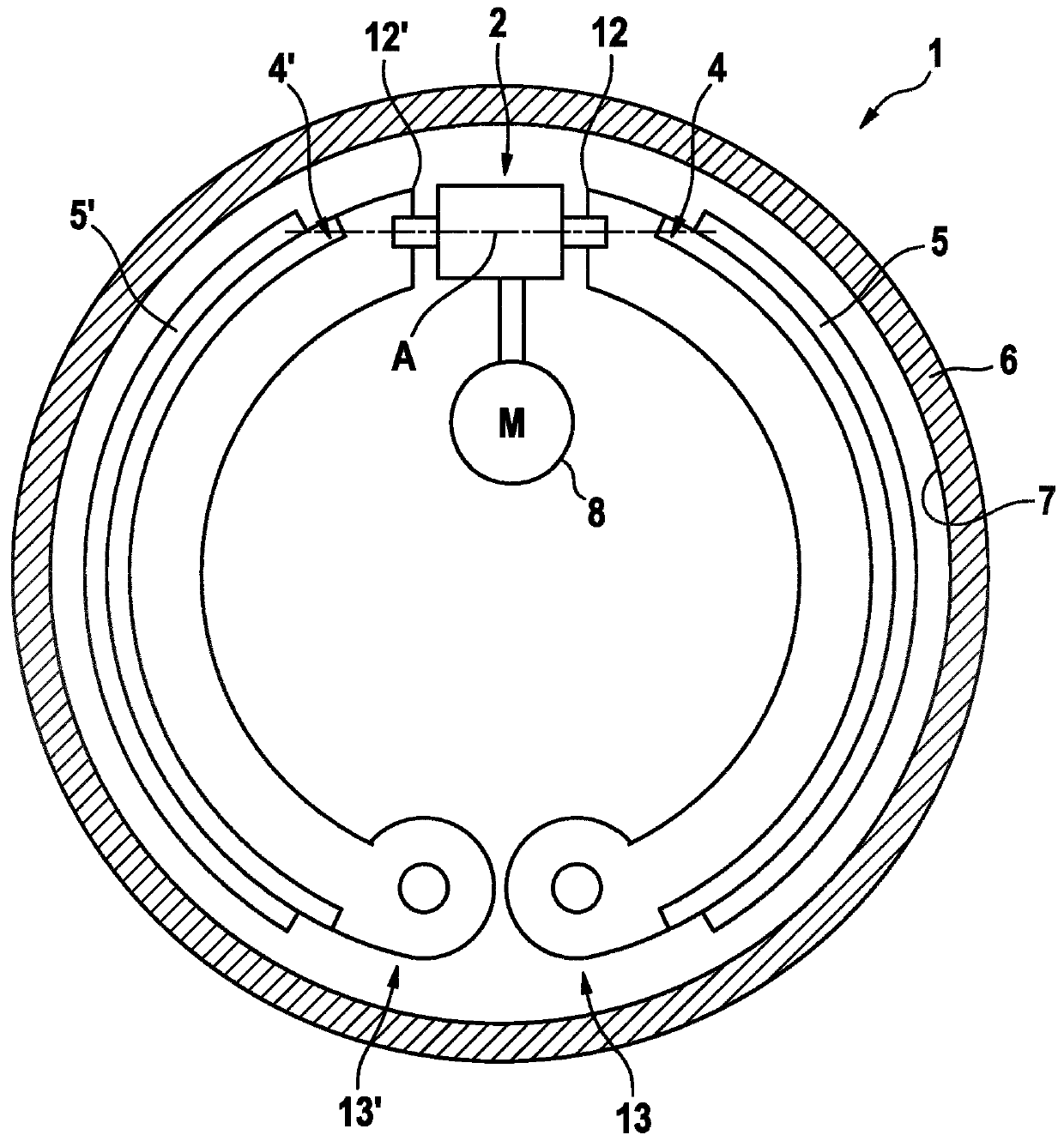

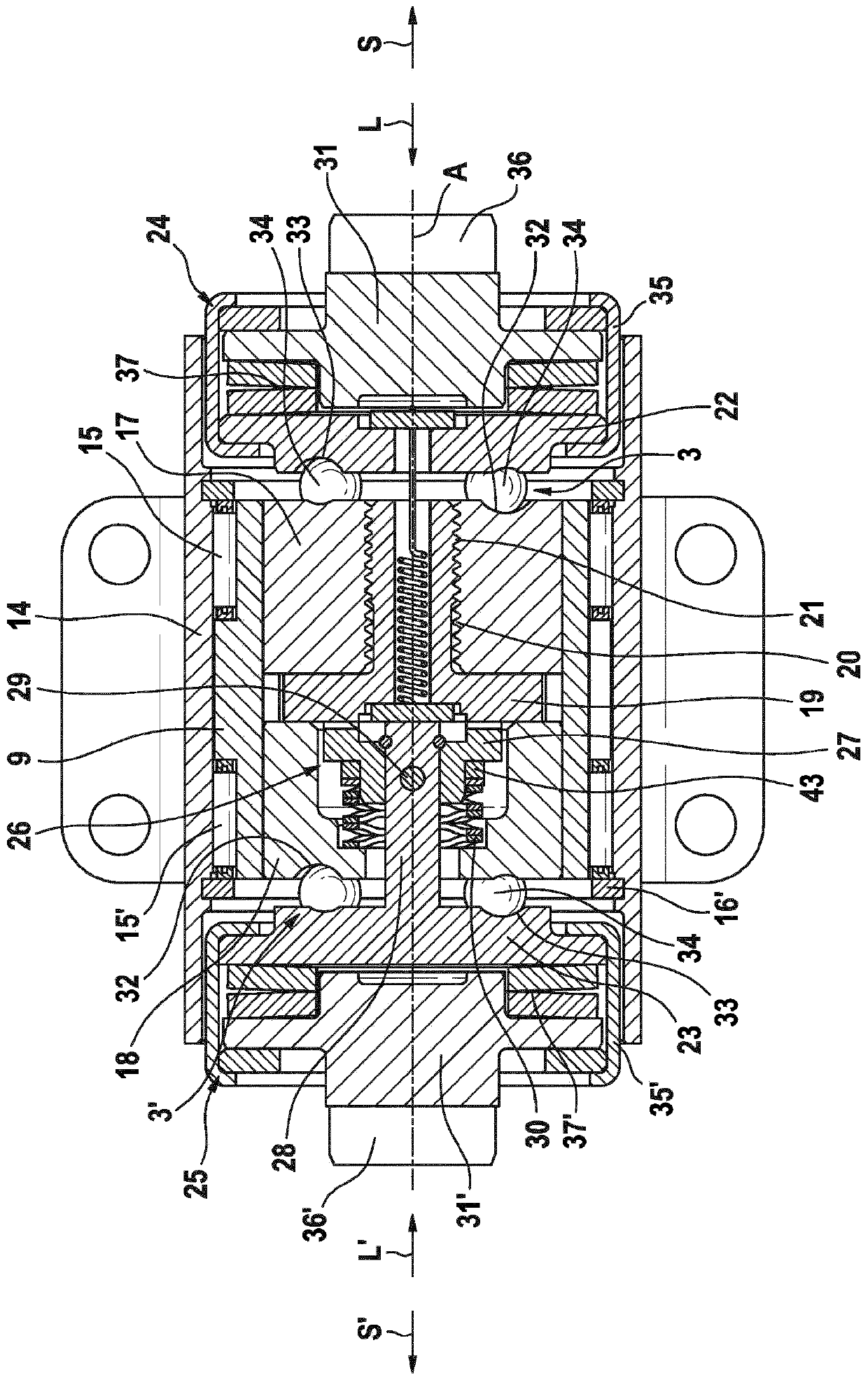

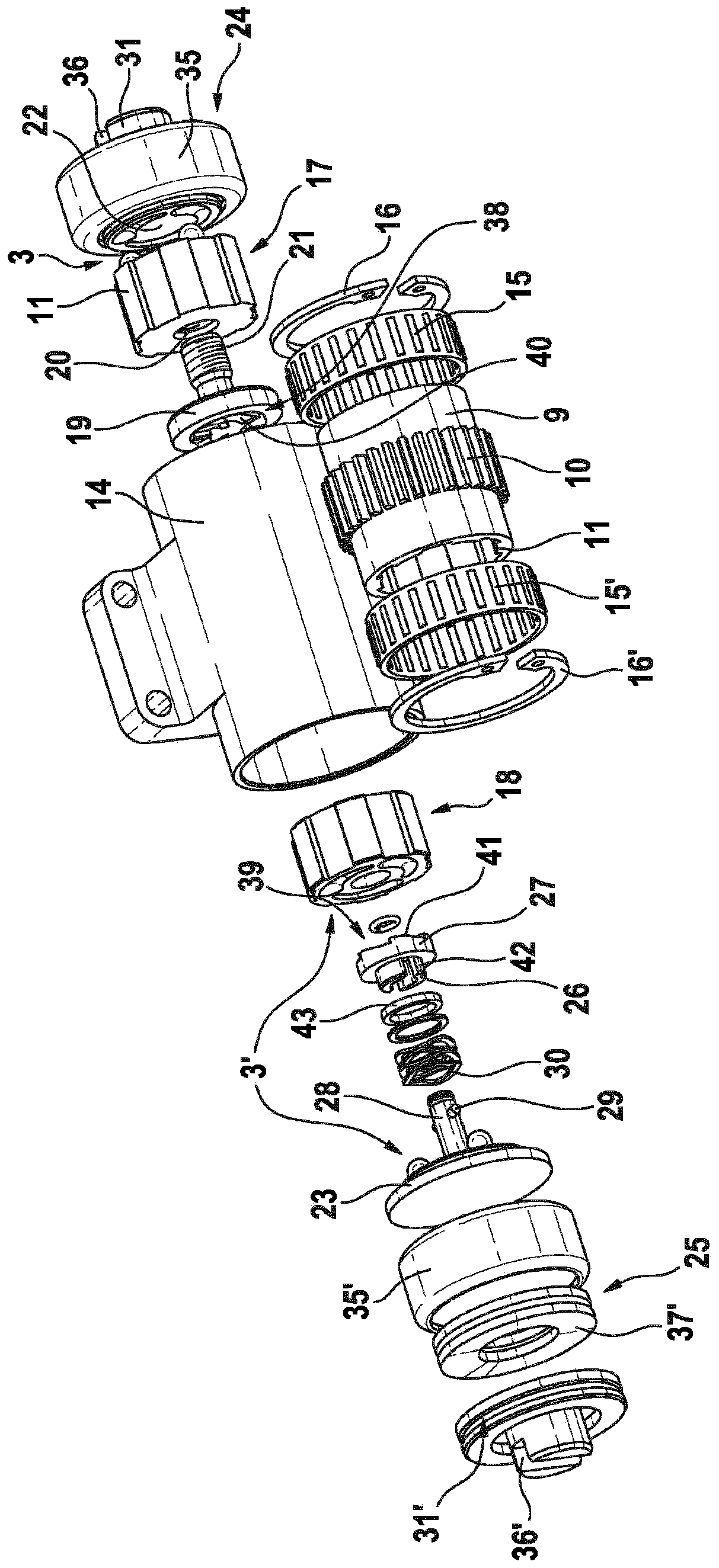

[0037] In order to bring the brake pads 5 , 5 ′ into contact evenly against the inner wall 7 , the two actuating pistons 17 , 18 are arranged axially floating and by means of the axial guide 11 in a rotationally fixed manner relative to the drive sleeve 9 In the drive sleeve 9. In the exemplary embodiment shown, the axial guide is formed by means of an axial toothing geometry, in particular an axial spline. Other embodiments such as lugs engaging in axial grooves etc. are also permissible within the invention.

[0038] The adjusting device 26 mainly comprises an adjusting piston 19 in force flow with the first actuating piston 17, and a locking sleeve 27 engaged with the adjusting piston 19 so that it cannot rotate relative to the second opening piston 28 but can It is arranged in an axially limited displacement manner and is elastically preloaded against the adjusting piston towards the adjusting piston.

[0039] The separate adjusting piston 19 is screwed into the first ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com