Intelligent cooking control method based on oxygen sensor

A control method and oxygen sensor technology, applied in the direction of control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problem that the oven or steamer cannot adjust the heating power in real time, the cooking effect is not ideal, and the cooking time is long and other issues to achieve the effect of realizing dynamic and intelligent control, ensuring rapid heating and efficient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] At present, ovens and steamers have entered more and more families of ordinary people as daily kitchen appliances. The working principle of cooking equipment such as ovens or steamers is mainly to adjust the heating power by detecting the temperature of the inner tank. However, this method cannot flexibly adjust the heating power according to the load placed in the inner tank. When the load on the inner tank is large, the temperature of the inner tank will not rise.

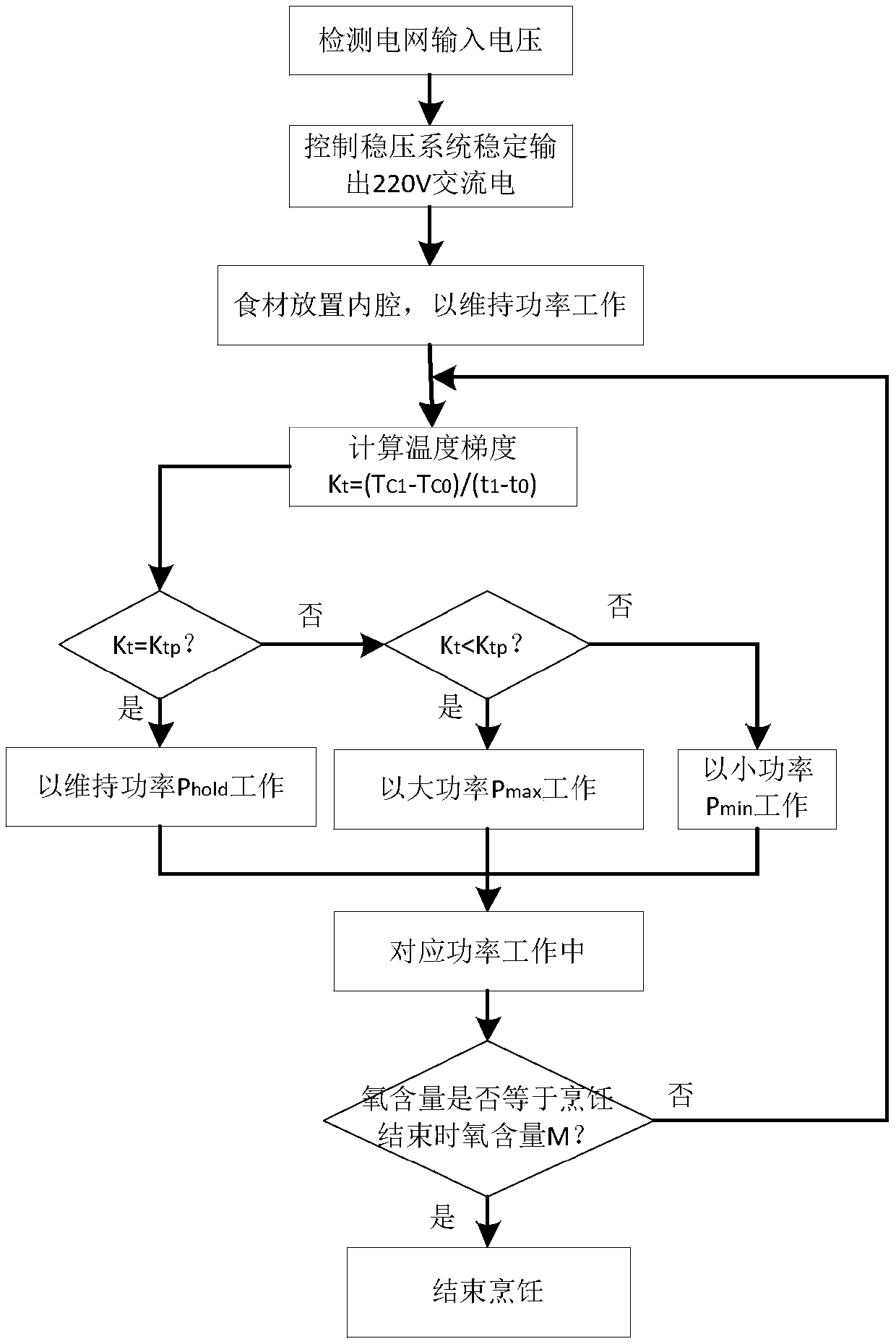

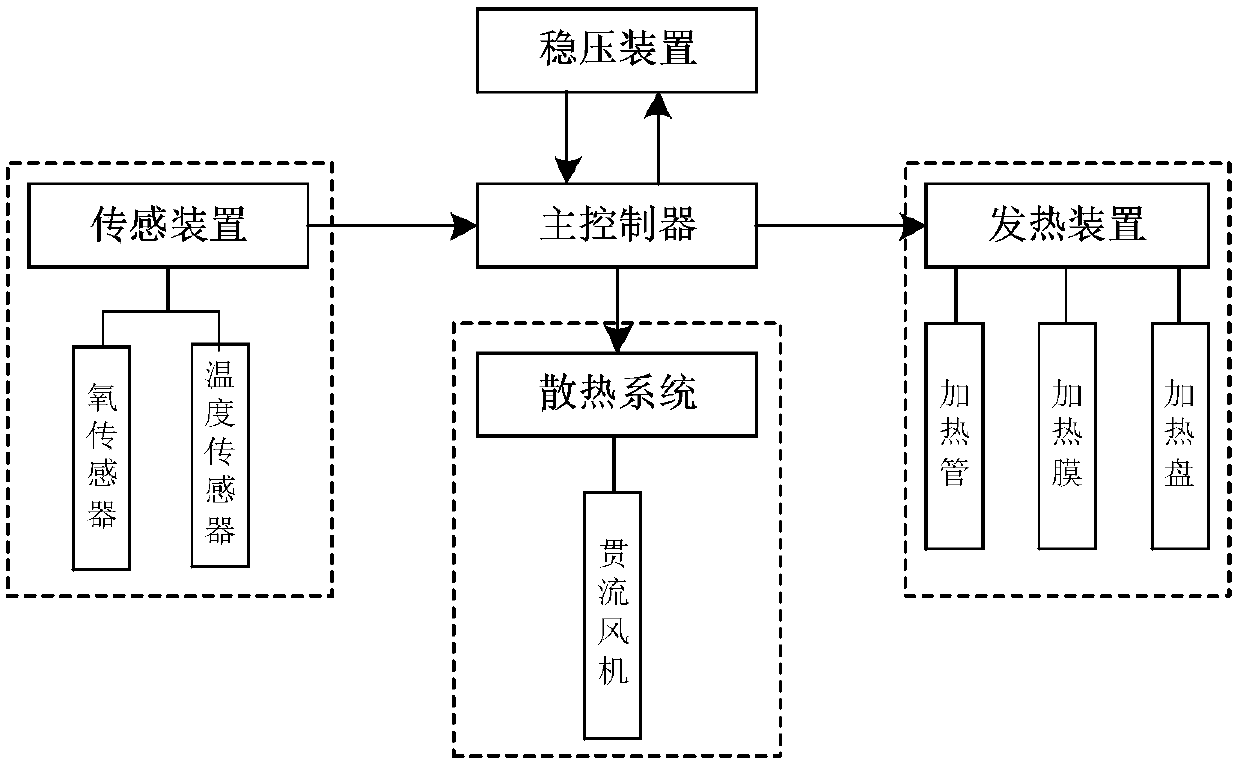

[0034] To this end, we propose a new smart cooking control method based on oxygen sensors, such as figure 2 As shown, the control method is realized by a control system that drives the cooking device, wherein the control system includes a main controller, a voltage stabilizing device, a sensing device, a heat dissipation device and a heating device, and the sensing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com