Filter screen assembly for wind turbine generator frequency converter

A technology for wind turbines and frequency converters, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of inconvenient disassembly and assembly, and achieve the effect of improving fixing, simple and convenient installation process, and low installation and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

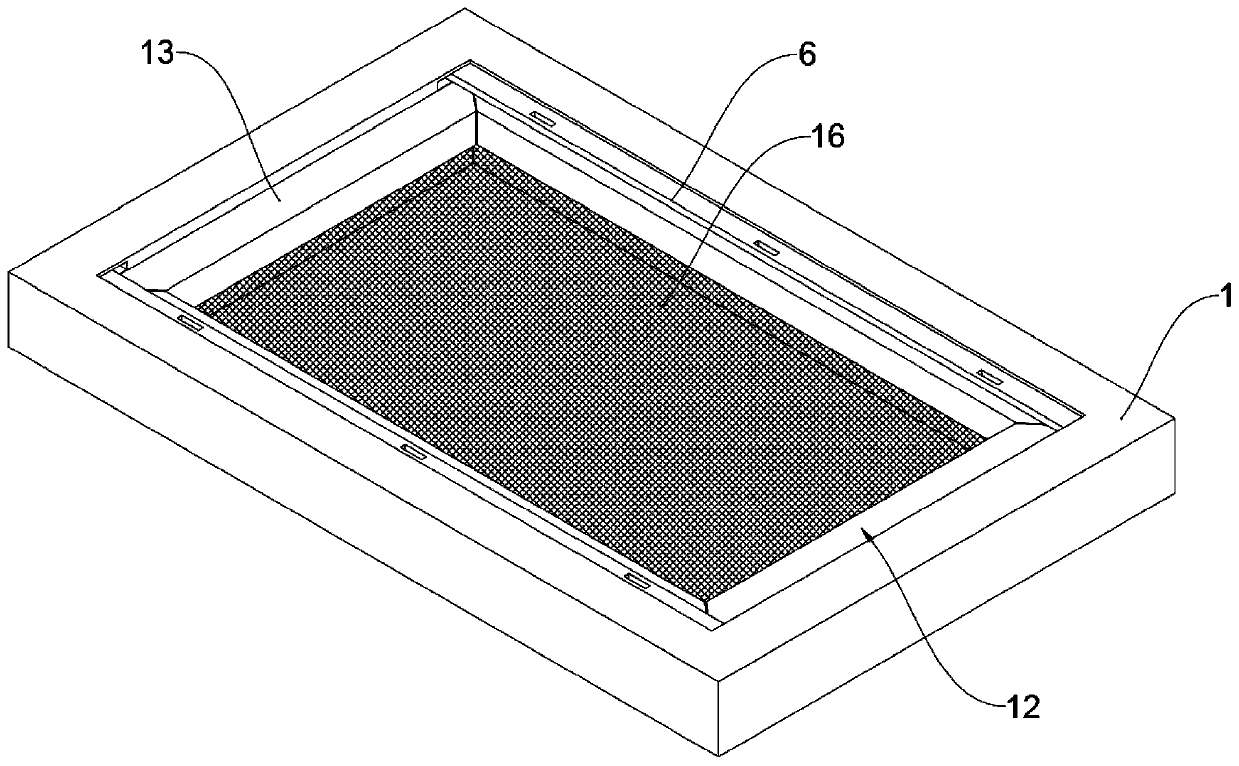

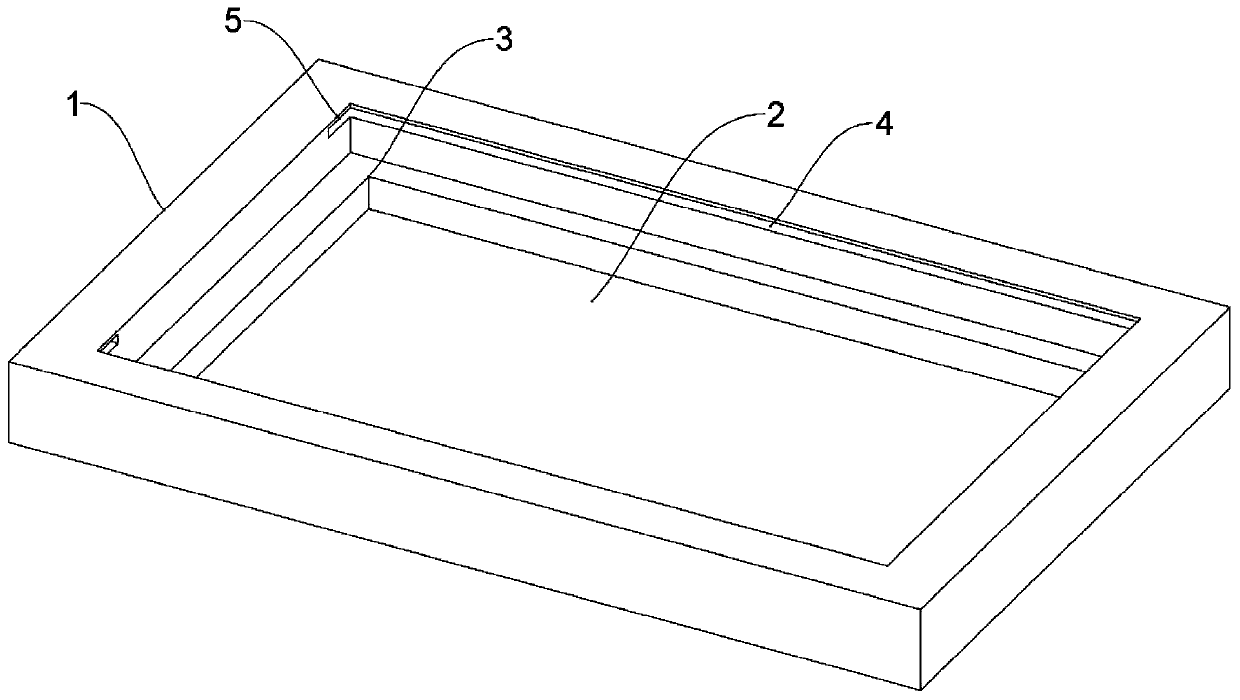

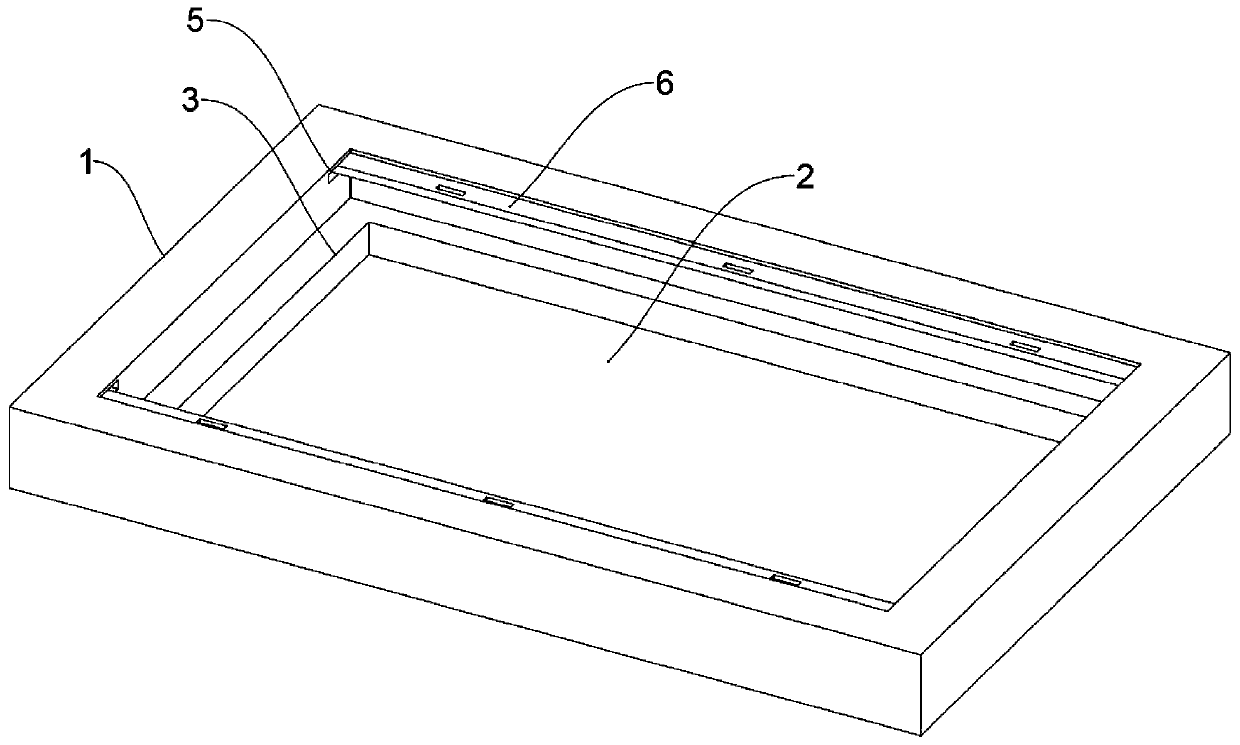

[0031] Such as Figure 1 to Figure 7 As shown, this embodiment provides a filter screen assembly for wind turbine frequency converters, including a fixed frame 1 and a rectangular channel 2 formed therein, a retaining frame 3 is arranged in the rectangular channel 2, and the four outer sides of the retaining frame 3 are The walls are uniformly fixed under the four inner walls of the fixed frame 1, and the top of the front side wall and the top of the rear side wall inside the fixed frame 1 are provided with a placement slot 4 with the same structure, and the top of the left side wall inside the fixed frame 1 and the top of the right side wall are respectively provided with snap slots 5 that communicate with the different ends of the same placement slot 4, and the interior of the placement slot 4 is provided with a slidable clamping plate 6, the width of the clamping plate 6 is the same as the depth of the placement slot 4, and the two ends of the clamping plate 6 are inserted ...

Embodiment 2

[0034] Such as Figure 1 to Figure 7 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0035] The filter mechanism 11 includes a rectangular filter frame 12. The rectangular filter frame 12 is composed of four aluminum alloy bars 13 and four metal buckles 14. The bottom of the aluminum alloy bar 13 is hollow and two bars parallel to the sides of the aluminum alloy bar 13 are arranged in the center. Bar 15, one end of the metal buckle 14 is inserted between the two clips 15 of an aluminum alloy bar 13 and the other end is clipped between the two clips 15 of the adjacent aluminum alloy bar 13, and all the clips 15 are fixed with Stainless steel filter screen 16.

[0036] In this embodiment, the rectangular filter frame 12 is formed by connecting and fixing the aluminum alloy strips 13 and the metal buckles 14. When installing, it is only necessary to align the adjacent aluminum alloy strips 13 first, and then insert the metal buckles 1...

Embodiment 3

[0038] Such as Figure 1 to Figure 7 As shown, this embodiment is further optimized on the basis of embodiment 2, specifically:

[0039] The stainless steel filter screen 16 is bonded to the clamping strip 15 through the sealing tape, and the rubber layer 17 is filled and fixed between the two clamping strips 15 on the aluminum alloy strip 13, and the stainless steel filter screen 16 is fixed by several rivets 18 driven into the rubber layer 17 live.

[0040] In this embodiment, the stainless steel filter 16 is fixed by the sealing rubber strip on the one hand, and fixed by inserting the rubber layer 17 through the rivet 18 on the other hand, which effectively improves the fixing reliability. Compared with snapping the filter into the center or inside, the removal efficiency is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com