Internal demoulding device and method for casting mold with long soft manipulator driven by fluid pressure

A technology of soft machinery and fluid pressure, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as excessive mold making, pressure leakage, and affecting the normal use of soft robotic arms, and achieve the effect of facilitating the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention are described in detail below.

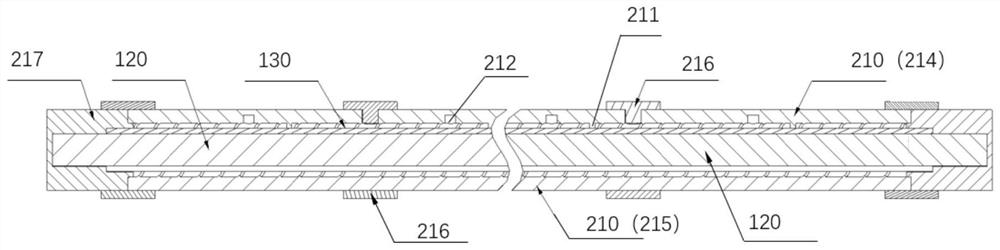

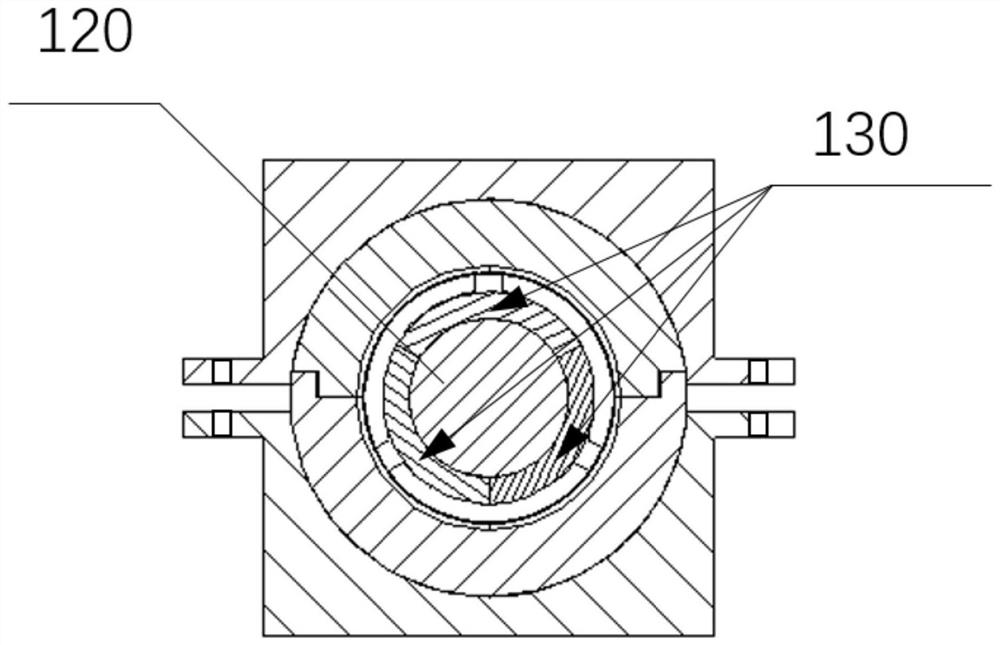

[0036] The present invention discloses a fluid pressure-driven long soft mechanical arm casting mold internal demoulding device and a preferred embodiment of the method, such as figure 2 with Figure 5 As shown, its setting includes two sets of shell moulds, one of which is an inner shell 210 for accommodating a cast body of a long soft manipulator, and one is an outer shell 110 for accommodating a cast body of a long soft manipulator, and The inner shell 210 or the outer shell 110 is provided with a mandrel 120 for supporting the cast body of the long soft manipulator. An accommodating space is formed between the mandrel 120 and the inner shell 210 or the outer shell 110 , and after being solidified by injection molding, a silicone soft elastic body, that is, the cast body of the long soft mechanical arm is formed.

[0037] In order to realize the casting process conveniently, a mandrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com