A chip-removing metal pipe drilling equipment

A technology for drilling equipment and metal pipes, which is applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., and can solve problems such as long time-consuming, inability to control the position and angle of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

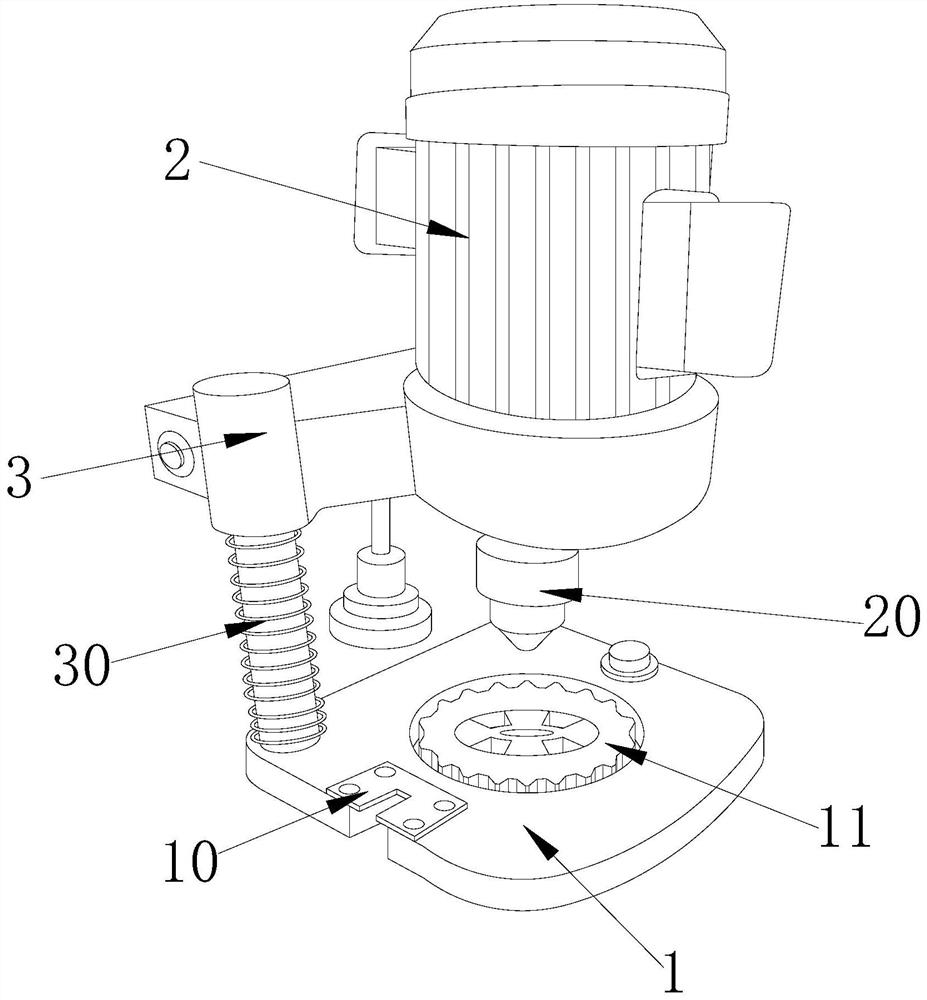

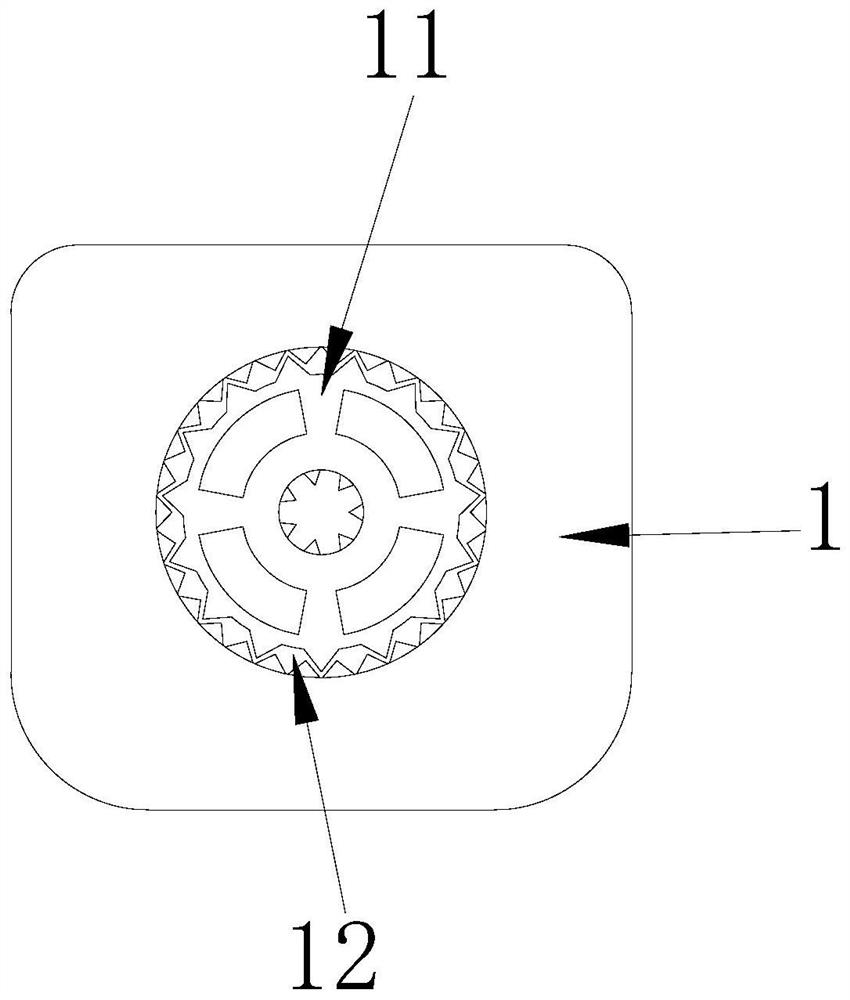

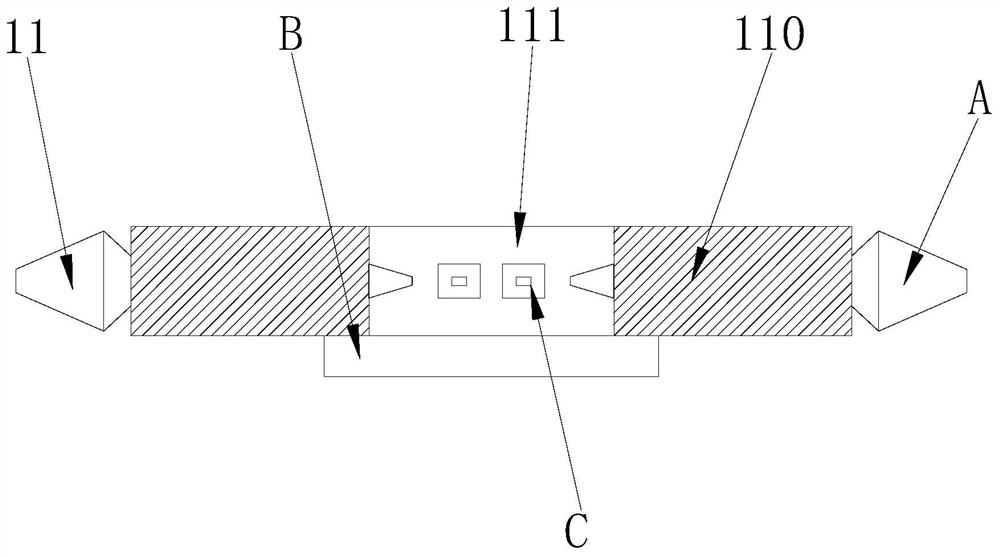

[0031] Embodiment 1: When in use, by placing the workpiece in the transmission groove 12 or in the rotation groove 111, the drill bit 20 is used to perform drilling work. When multiple drilling holes are required on the same workpiece, the pusher 120 Push the rotating plate 110 to rotate, and at the same time drive the rotating groove 111 to rotate during the rotation of the rotating plate 110, so that the workpieces on the upper surface of the rotating plate 110 can be driven to rotate, thereby pushing the workpiece to perform multi-directional drilling; The card plate E on the 120 is driven on the guide groove E1, so that the card plate E drives the card teeth D to move around the circle, and at the same time drives the card teeth D to push the rotary plate 110 to rotate; when the card teeth D push the rotary plate 110 When the push head A on the top rotates, it also drives the workpiece on the upper surface of the rotating plate 110 to rotate, thereby completing the multi-di...

Embodiment 2

[0032] Embodiment 2: When the rotating plate 110 rotates, it drives the rotating rod B to rotate at the same time, thereby driving the sawtooth C inside the rotating groove 111 to rotate, and the sawtooth C will push the workpiece inside the rotating groove 111 to perform multi-directional Drilling; at the same time, during the rotation of the rotating groove 111 and the rotating plate 110, metal debris will be pushed into the bushing plate 121, and then the debris will be introduced into the bottom of the bushing plate 121 through the holes on the bushing plate 121, and then pass through the bushing plate 121 The slag suction pipe 122 below cleans up the residue to prevent the residue from accumulating in the transmission groove 12 .

[0033] The technical progress that the present invention obtains relative to the prior art is:

[0034]1. The clamping plate on the pusher moves in a circle on the guide groove, thereby pushing the pusher on the turntable to rotate, and the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com