Split type multifunctional deep hole drilling machine

A deep hole drilling machine, multi-functional technology, applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., can solve the problem of high temperature of the drill bit, save time, improve accuracy and efficiency , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

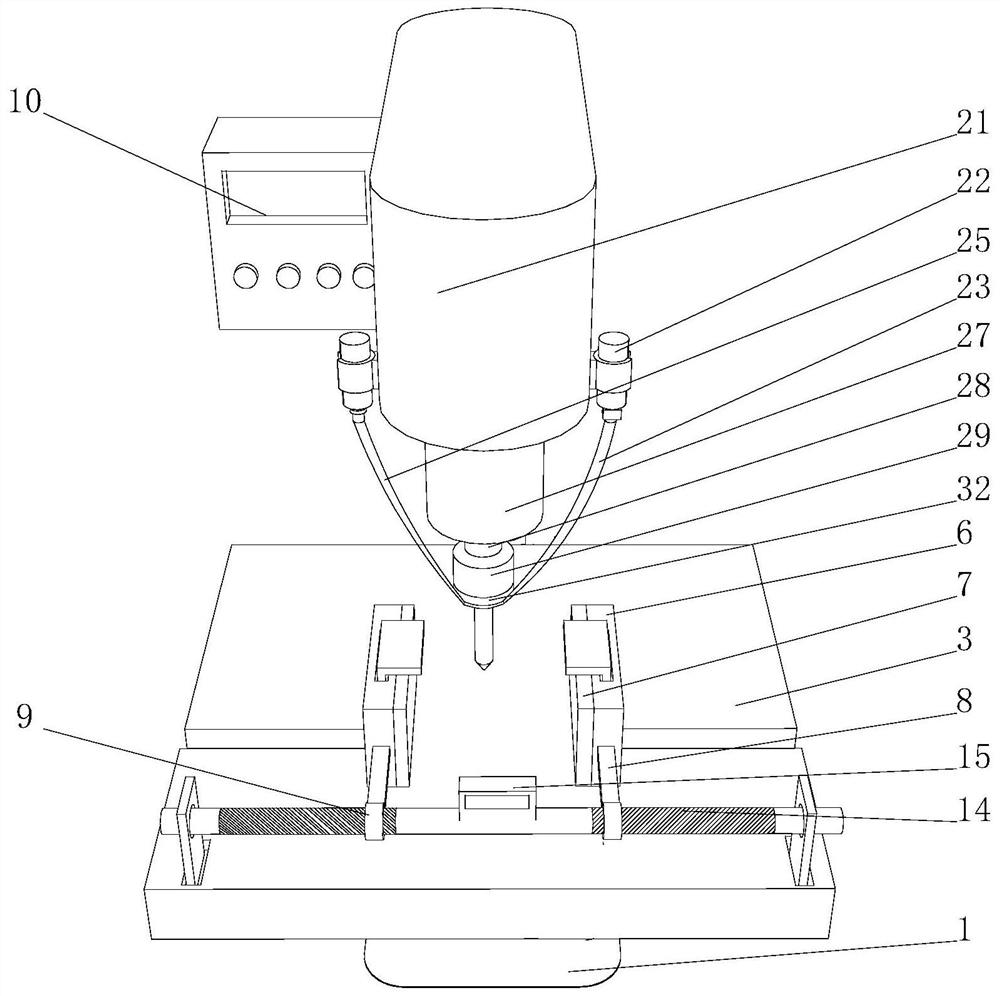

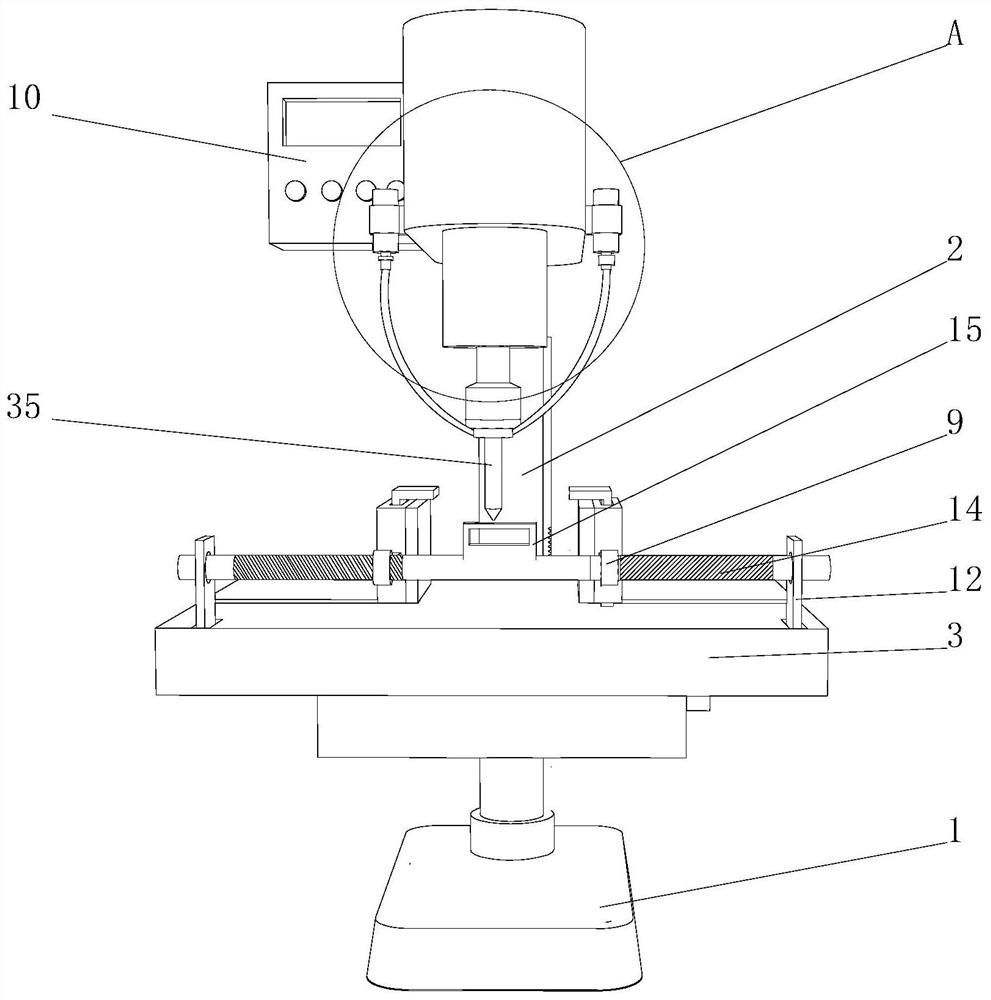

[0031] Such as Figure 1-Figure 7 As shown, the present invention provides a split-type multifunctional deep hole drilling machine, comprising a base 1, a pillar 2, a workbench 3 and a clamping device 6, the top of the base 1 is fixedly connected with a pillar 2, and the front of the pillar 2 is fixedly connected with a The workbench 3 is provided with a chute 4 at the left and right ends of the top of the workbench 3, the inner wall of the chute 4 is slidably connected with a sliding block 5, and the top of the sliding block 5 is fixedly connected with a clamping device 6, and the clamping device 6 The fronts of the connecting rods 8 are fixedly connected with connecting rods 8, and the opposite surfaces of the clamping device 6 are provided with damping sponges 7, the fronts of the connecting rods 8 are fixedly connected with threaded sleeves 9, and the inner walls of the threaded sleeves 9 are all threaded with two-way bolts 14 , the base 1 is used to fix and support the sp...

Embodiment 2

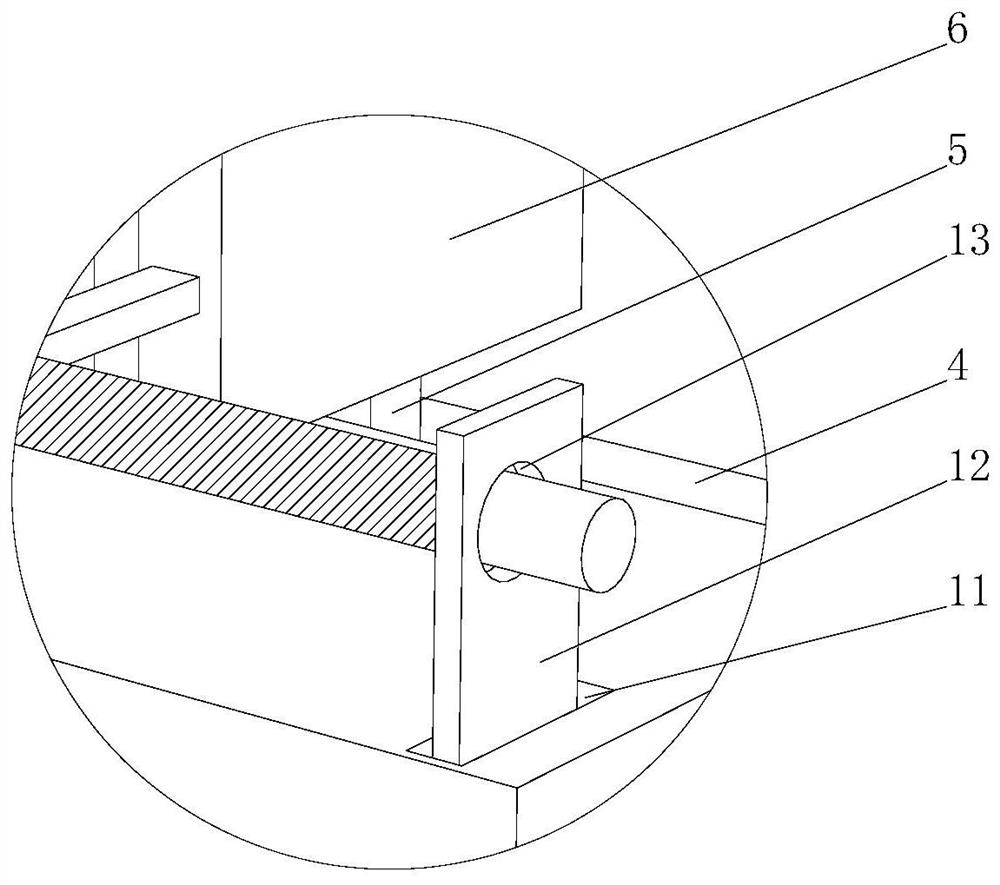

[0033] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the top left and right sides of the workbench 3 are provided with fixing grooves 11, the inner wall of the fixing groove 11 is movably connected with a fixing plate 12, and the fixing plate 12 The side is provided with a circular groove 13, and the fixed plate 12 is respectively movably connected with the left and right ends of the two-way bolt 14 through the circular groove 13 provided. Movable slot 16, the bottom of the inner wall of the movable slot 16 is provided with a fixed rod 17, the top of the fixed rod 17 is provided with a lift chamber 18, the inwall of the lift chamber 18 is movably connected with a push-pull rod 19, and the top of the push-pull rod 19 is fixedly connected with a top fixed block 20. Install the threaded sleeve 9 on the two-way bolt 14, insert both ends of the two-way bolt into the circular groove 13, then insert the fixing plate 1...

Embodiment 3

[0035] Such as Figure 1-7As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the top of the pillar 2 is fixedly connected with a working box 21, and the left side of the working box 21 is provided with a numerical control device 10, and the numerical control device 10 The function is to adjust and control the split multi-functional deep hole drilling machine. The right side of the working box 21 is movably connected with a cooling liquid storage bottle 22 through a fixed device provided. Cooling liquid, the bottom of the cooling liquid storage bottle 22 is provided with a liquid inlet pipe 23, and the top of the liquid inlet pipe 23 is provided with an electric control valve 24, which controls the numerical control device 10 to control the closing and opening of the electric control valve 24, the working box The bottom of 21 is fixedly connected with a cylinder 27, and the output end of the cylinder 27 is movably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com