Fixing device for processing tooth palm journal

A fixing device and journal technology, which is applied in the field of fixing devices, can solve the problems of high difficulty in product processing and debugging, long mold changing operation time, and complicated V-shaped block design, so as to achieve low processing and debugging difficulty, shorten debugging time, online The effect of measuring convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

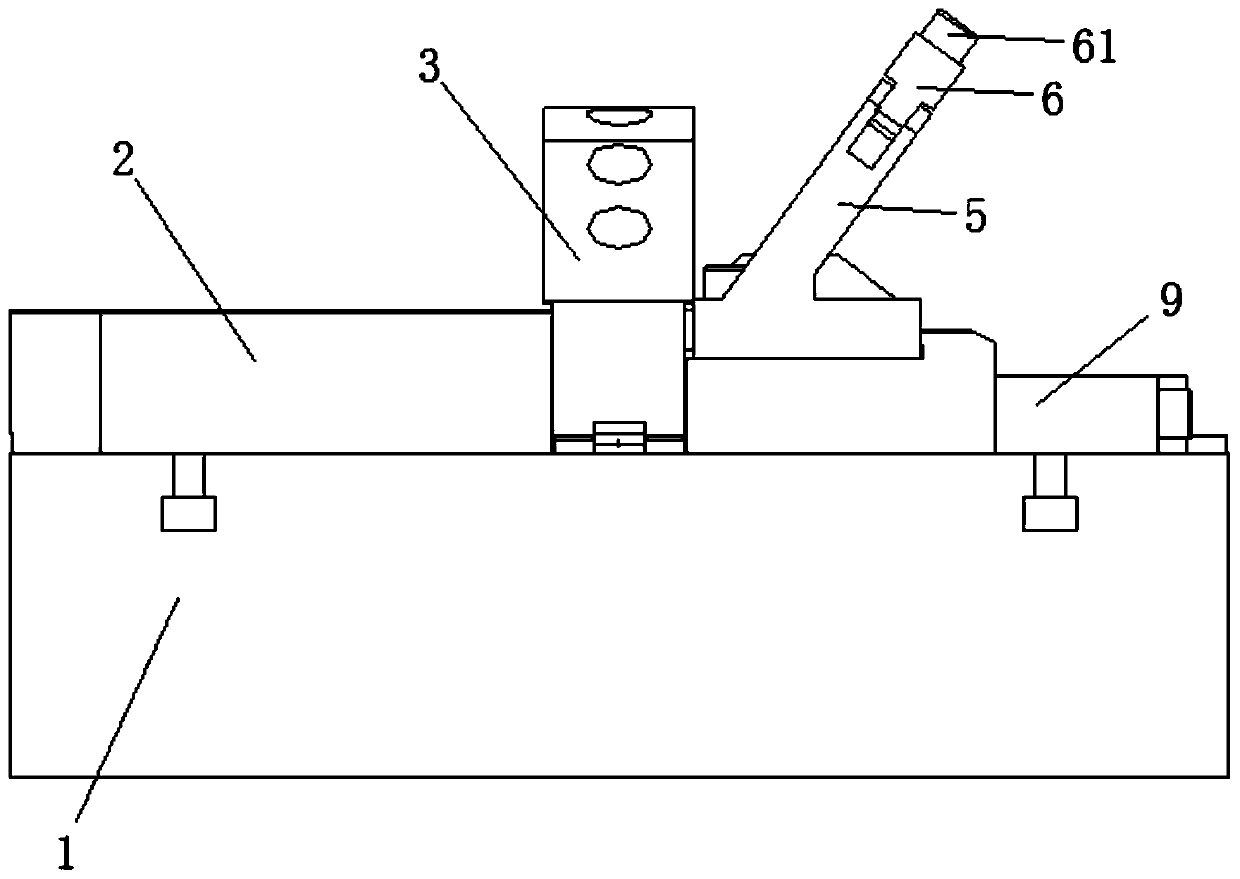

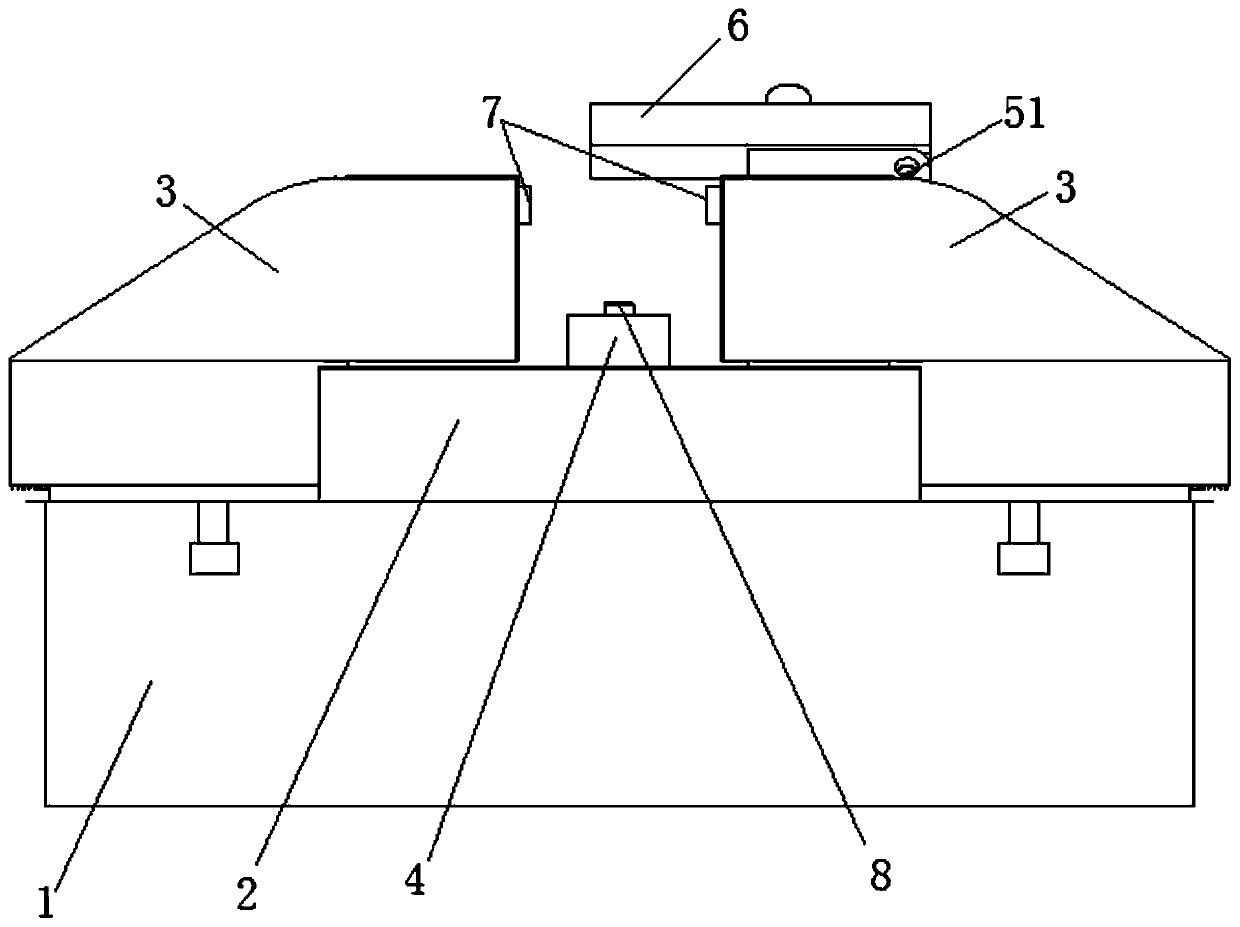

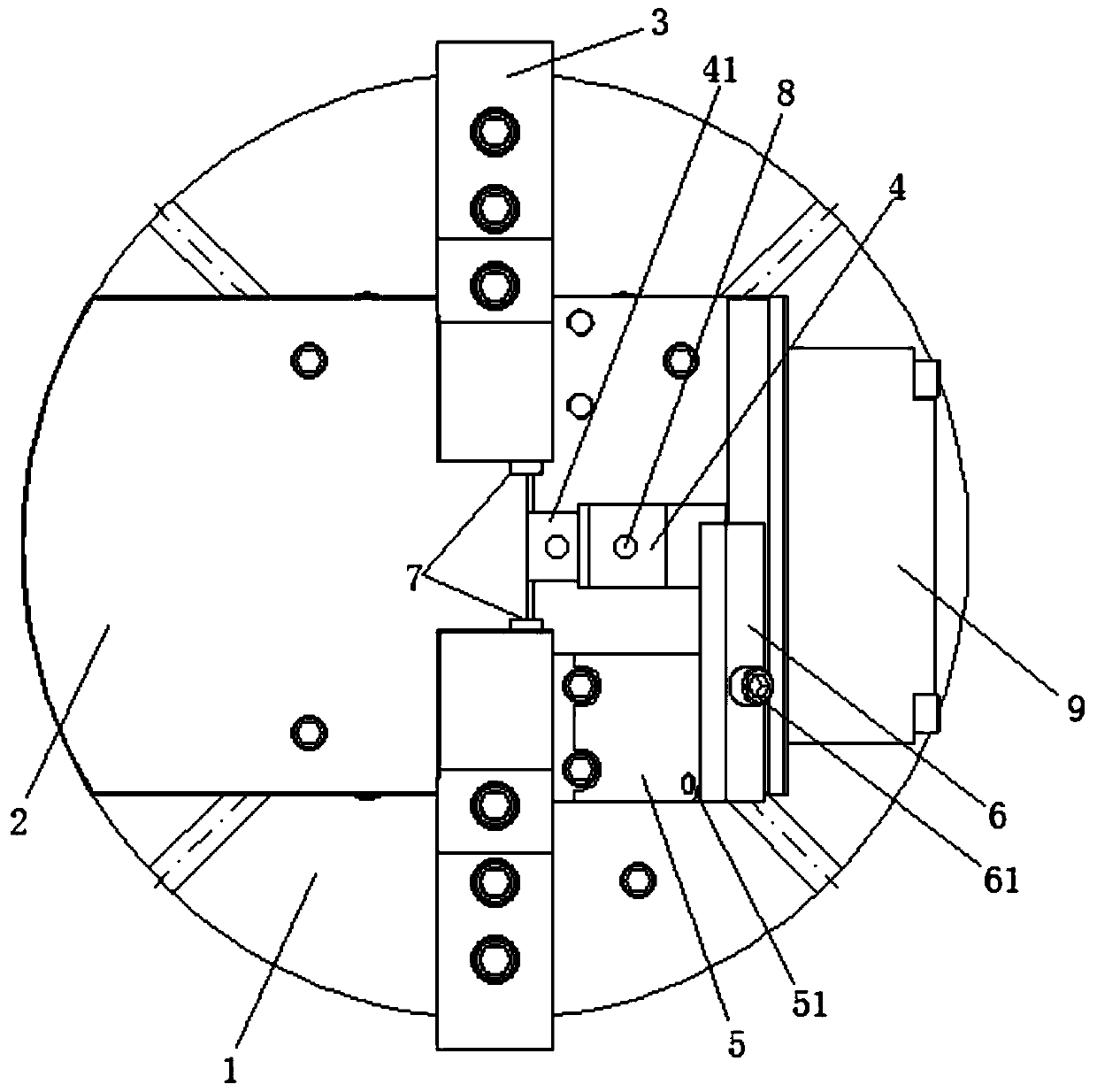

[0028] as attached Figure 1-6 As shown, a fixing device for processing the journal of a tooth palm includes a chuck 1, a positioning plate 2, a claw 3, a positioning block 4, a pressing arm seat 5 and a pressing arm 6; the chuck 1 is provided with a positioning plate 2; the chuck 1 is a hydraulic double-jaw chuck; a pair of jaws 3 moving toward the center are arranged on both sides of the positioning plate 2, and the jaws 3 are symmetrically arranged on both sides of the positioning plate 2; On the opposite side of the claw 3, a claw positioning pin 7 is provided; the pin head of the claw positioning pin 7 is a plum blossom top; the center of the plum blossom top is a concave plane 71 lower than the top protrusion 72; on the claw 3 side On one side of the facade, a positioning block 4 is arranged on the center line of the positioning plate 2; a radial positioning pin 8 is arranged on the positioning block 4; a wedge-shaped pressing block 41 is provided on the positioning bloc...

Embodiment 2

[0031] as attached Figure 1-3 , shown in 5-6, a kind of fixing device of processing tooth palm journal, comprises chuck 1, positioning plate 2, claw 3, positioning block 4, pressing arm seat 5 and pressing arm 6; A positioning plate 2 is provided; the chuck 1 is a hydraulic double-jaw chuck; a pair of claws 3 moving toward the center are arranged on both sides of the positioning plate 2, and the claws 3 are symmetrically arranged on both sides of the positioning plate 2. side; the opposite side of the jaw 3 is provided with a jaw positioning pin 7, and the top of the jaw positioning pin 7 is flat; on one side of the side elevation of the jaw 3, the center line of the positioning plate 2 is set There is a positioning block 4; radial positioning pins 8 are set on the positioning block 4; a wedge-shaped pressing block 41 is arranged on the positioning block 4, and the positioning block 4 is connected with the positioning plate 2 by bolts through the wedge-shaped pressing block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com