Train brake cylinder non-pressure head

A technology of brake cylinder and pressure head, applied in railway braking system and other directions, can solve problems such as uneven ventilation, deformation, loud noise, etc., and achieve the effect of stable structure, reduced noise pollution and good mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

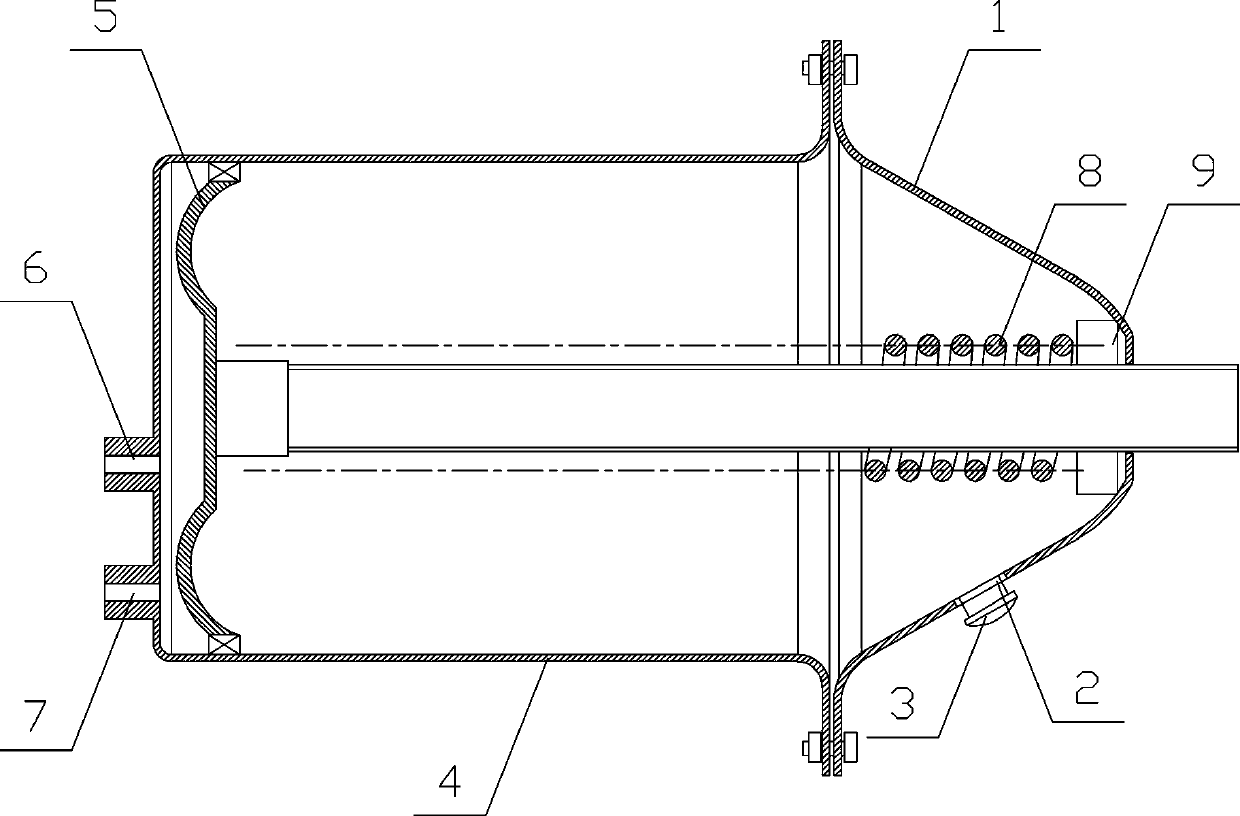

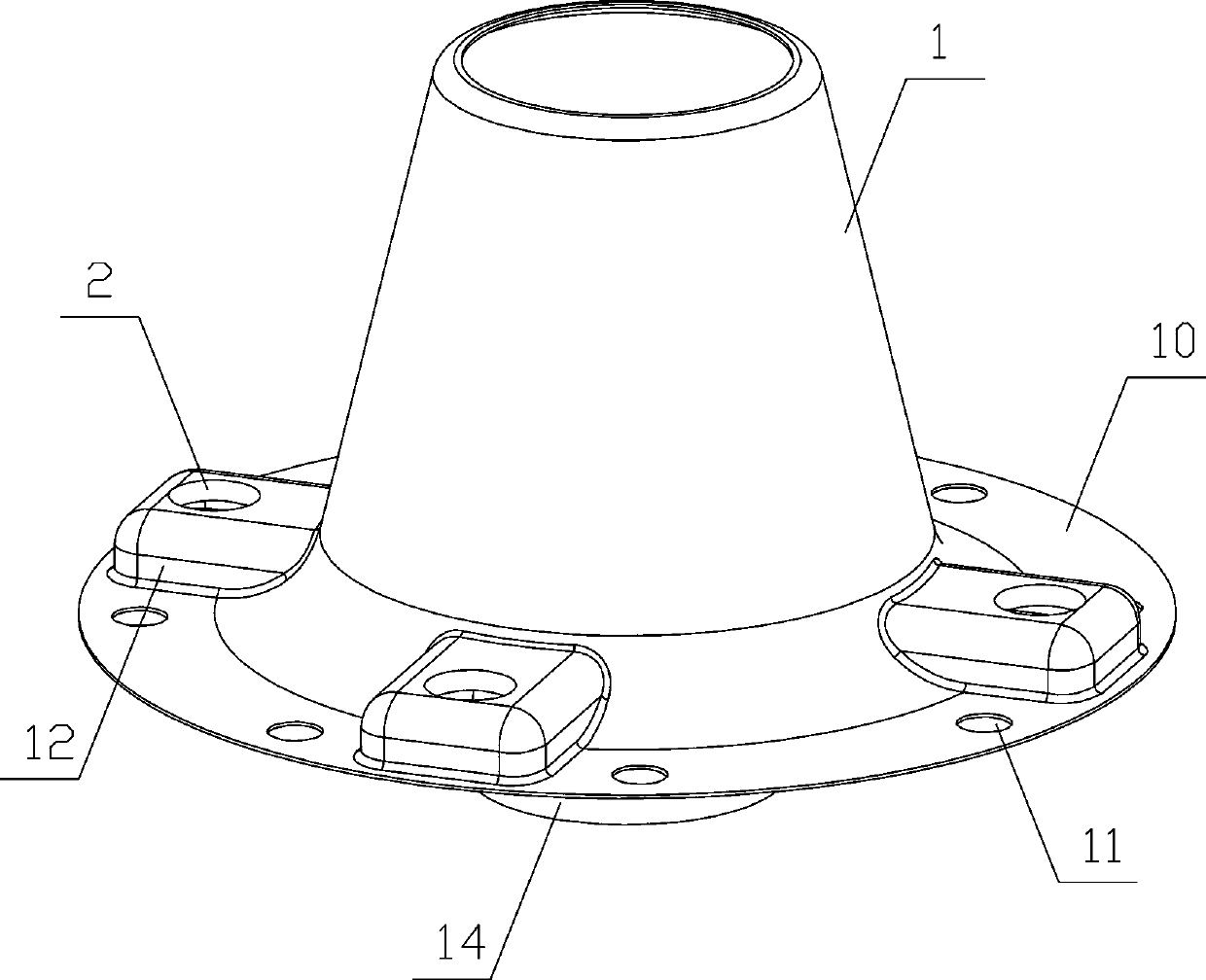

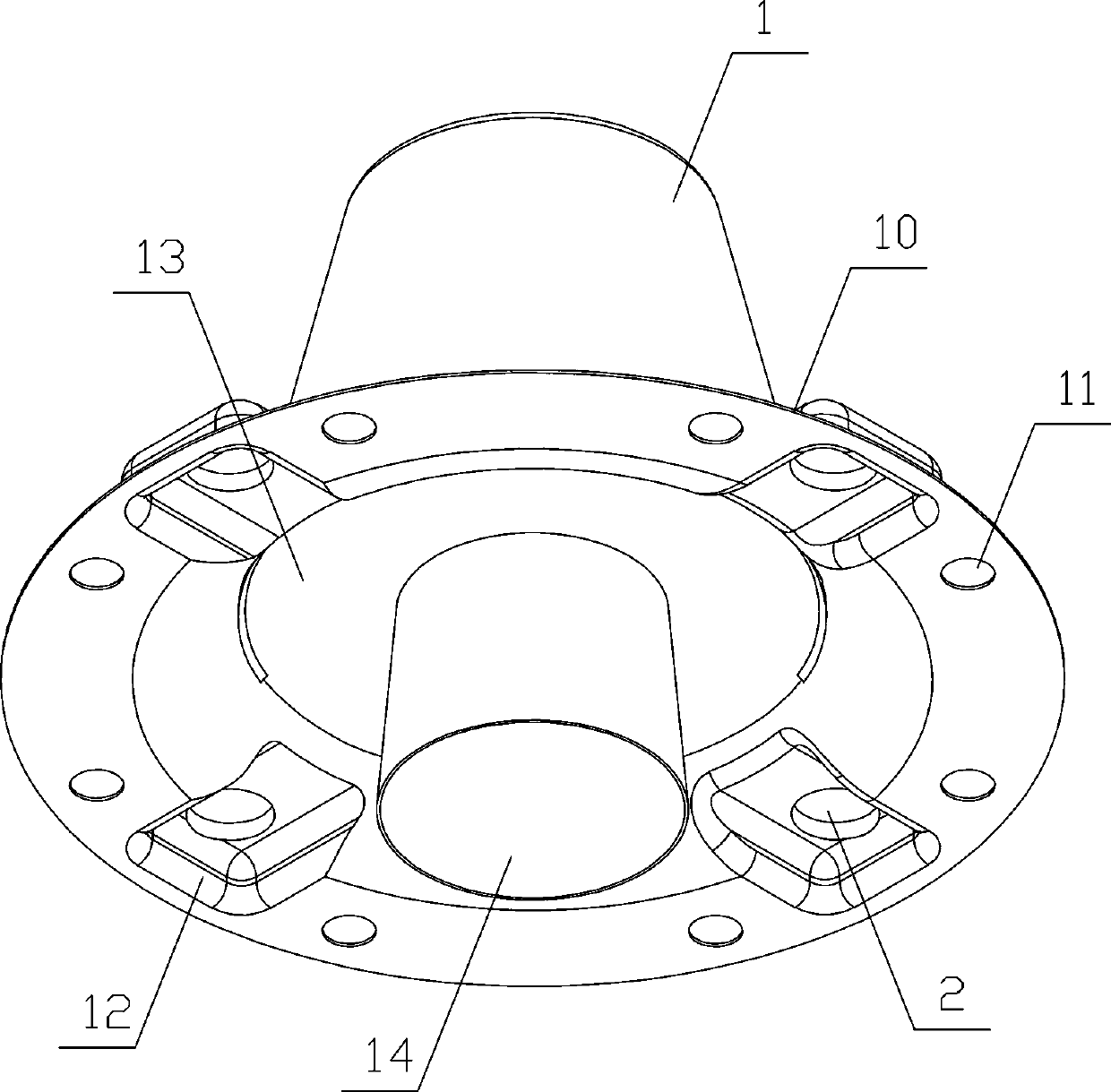

[0014] see Figure 2-4 , the present invention provides a train brake cylinder without pressure head, which has a trumpet-shaped body 1, the diameter of the rear port of the body 1 is larger than the diameter of the front port; the rear port of the body 1 is provided with an annular edge 10 arranged toward its outside , the annular edge 10 is arranged perpendicular to the central axis of the body 1, and an assembly hole 11 and four air chambers 12 uniformly distributed along the circumference are arranged on the annular edge 10, and each air chamber 12 is equipped with a vent hole 2, and An assembly hole 11 is provided on both sides of each air chamber 12; a liner arranged coaxially with it is welded in the body 1, and the liner is composed of an annular liner plate 13 and a central pipe 14. The edge of the outer ring of the inner liner 13 is welded as a whole with the inner side wall of the body 1, the front end of the center pipe 14 is welded vertically on the edge of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com