Novel lift door control system

A control system and elevator door technology, which is applied to elevators, transportation and packaging in buildings, can solve problems such as insufficient reliability, cumbersome wiring, and increased costs, so as to save wiring harness costs, reduce creepage distance, and increase reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

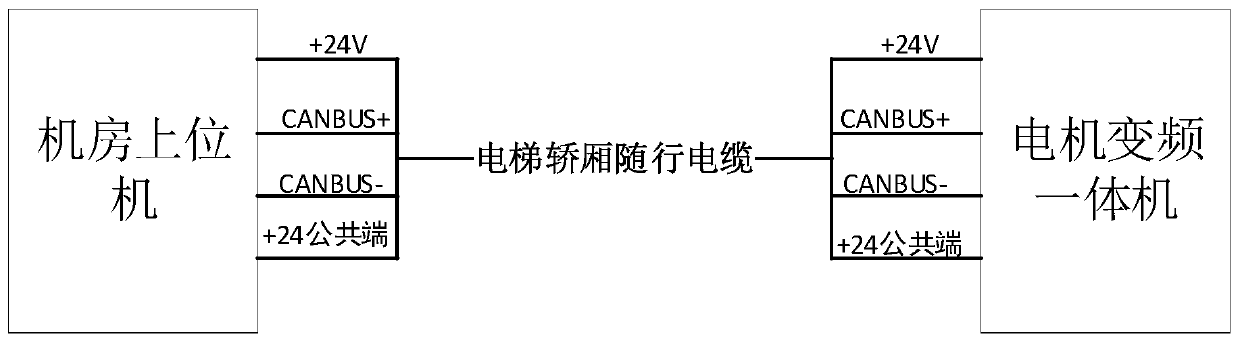

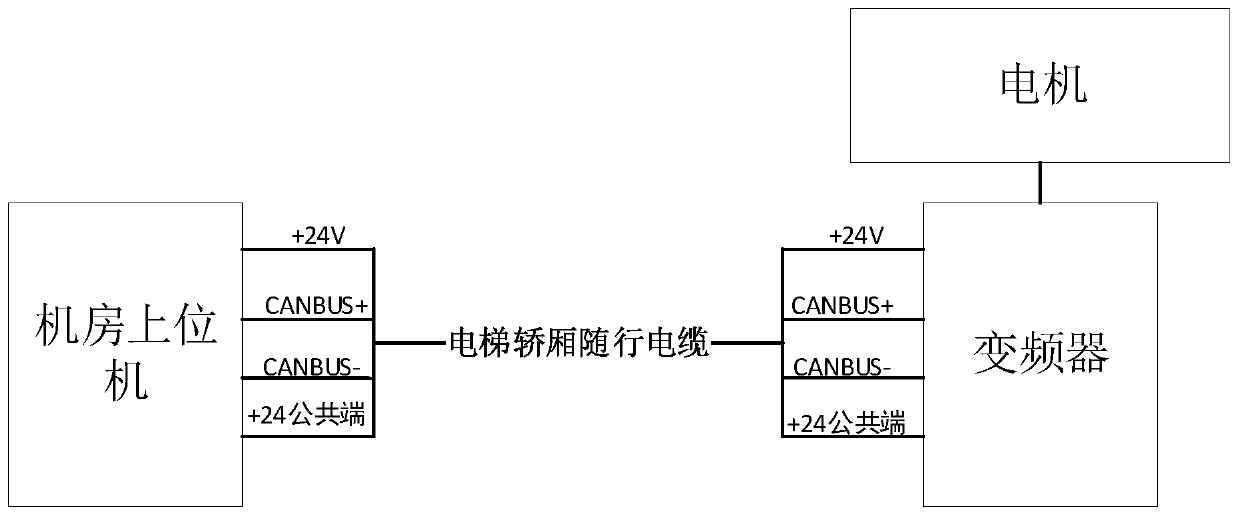

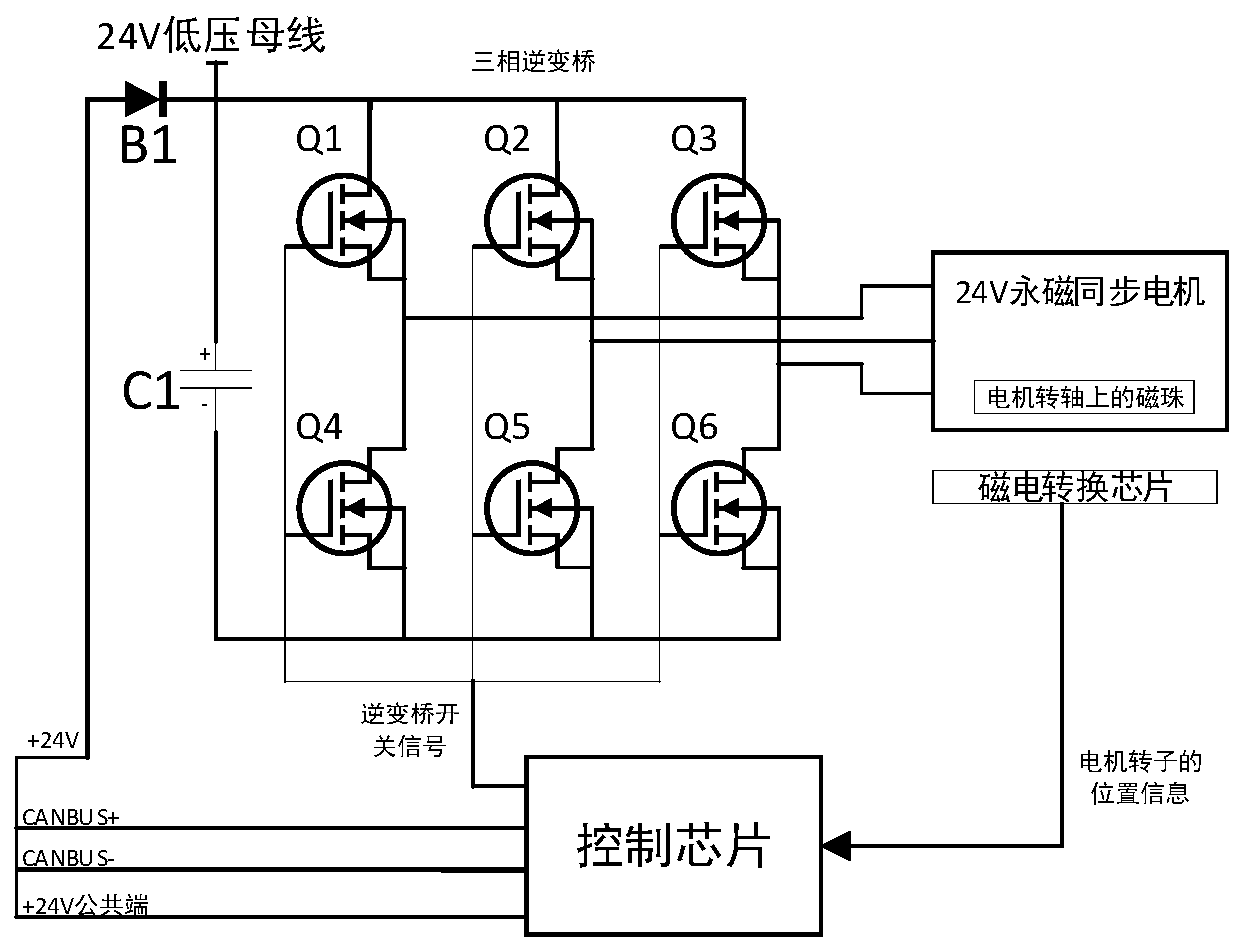

[0046] The embodiment of the present invention discloses a novel elevator door control system, such as Figure 1-7As shown, it includes: computer room upper computer 1, motor inverter integrated machine 2; wherein, the computer room upper computer is provided with +24V port, CANBUS+ port, CANBUS- port, +24V public port;

[0047] The motor-frequency converter integrated machine includes: a motor 21 and a frequency converter 22; the frequency converter is connected to the motor;

[0048] The frequency converter is also provided with +24V ports, CANBUS+ ports, CANBUS- ports, and +24V public ports; the upper computer in the machine room realizes the connection between each port and the port with the same name on the frequency converter through the elevator car accompanying cable. connect;

[0049] The bottom of the motor is provided with a receiving slot, and the frequency converter is arranged in the receiving slot; the motor is a 24V permanent magnet synchronous motor.

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com