Process and system for preparing high-strength blocky active lime from carbide slag

A technology of active lime and calcium carbide slag, applied in the field of industrial waste recycling, can solve the problems of difficult processing of calcium carbide slag, reduce the cost of calcium oxide, etc., and achieve the effects of low investment cost and operating cost, saving land resources and high purity

Pending Publication Date: 2020-05-29

ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] Aiming at the deficiencies in this field, the present invention provides a process for preparing high-strength massive active lime from calcium carbide slag. After drying, calcination, impurity removal and ball making of the industrial by-product calcium carbide

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

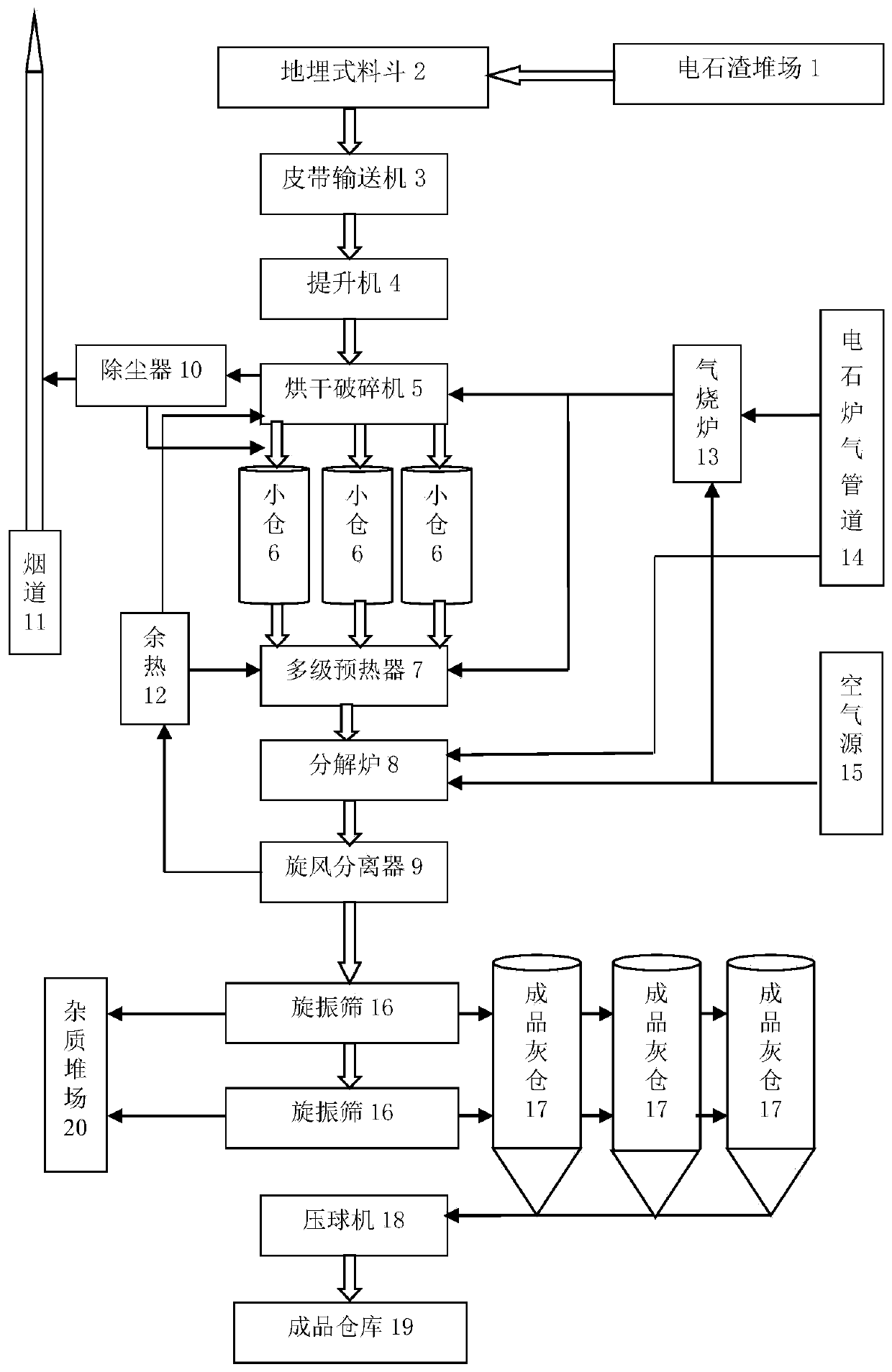

The invention discloses a process and a system for preparing high-strength blocky active lime from carbide slag. The process comprises the steps: (1) crushing carbide slag in a drying crusher and enabling the crushed carbide slag to enter a multistage preheater after being dried by high-temperature dry gas, wherein the high-temperature dry gas comes from a gas burning furnace and a cyclone separator, the high-temperature gas from the gas burning furnace and the cyclone separator is taken as a heat source of the multistage preheater, and the high-temperature gas is generated by burning calciumcarbide furnace gas in the gas burning furnace to provide heat; (2) enabling the carbide slag preheated by the multi-stage preheater and high-temperature gas to enter a decomposing furnace together tobe calcined and decomposed, introducing air into the decomposing furnace, and taking the calcium carbide furnace gas and heat generated by burning of the calcium carbide furnace gas as a heat source;(3) collecting calcium oxide obtained by calcining and decomposing through the cyclone separator, removing impurities, feeding an obtained product into a finished product ash bin, pressing the product into blocky active lime, and feeding the blocky active lime into a finished product warehouse; and enabling high-temperature gas obtained after calcination decomposition to enter the drying crusherand the multi-stage preheater again through the cyclone separator.

Description

technical field [0001] The invention relates to the technical field of industrial waste recycling, in particular to a process and a system for preparing high-strength massive active lime from carbide slag. Background technique [0002] In 2016, the production capacity of calcium carbide in my country was 45 million tons / year, and the output was 27.3 million tons / year (the statistics of 220 calcium carbide enterprises by China Carbide Industry Association), the domestic consumption was 27.16 million tons / year, and the export was 140,000 tons / year, according to the consumption of 1t Calcium carbide produces 1.2t of carbide slag, about 32.6 million tons of carbide slag per year. These discarded carbide slags not only take up valuable land resources, but also pollute nearby soil and water bodies. Therefore, the treatment of carbide slag is an important task to solve environmental pollution and enterprise survival. At present, the utilization and research of calcium carbide slag...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01F11/04

CPCC01F11/04C01P2006/80

Inventor 莫建松倪海波李福才王岳军陈美秀陈永军

Owner ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com