A Centrifugal Vortex Ballast Water Filtration Method with Adaptive Cleaning Function

A filtration method and ballast water technology, applied in separation methods, centrifugal separation water/sewage treatment, filtration and separation, etc., can solve problems such as reducing seawater flow rate, filter clogging, chemical pollution, etc., and achieve high ballast efficiency and equipment. Simple operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

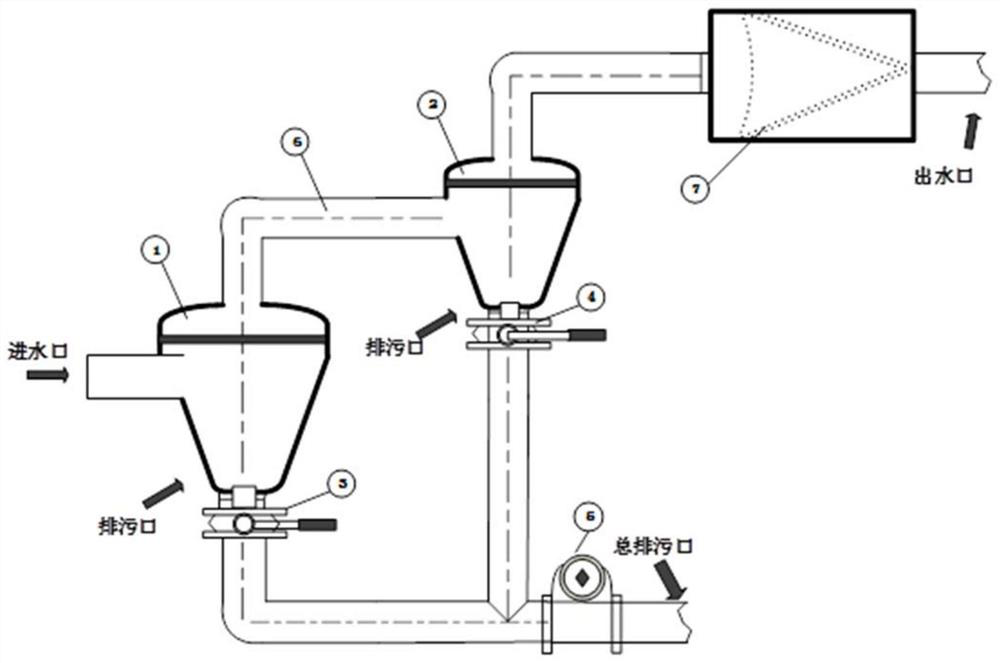

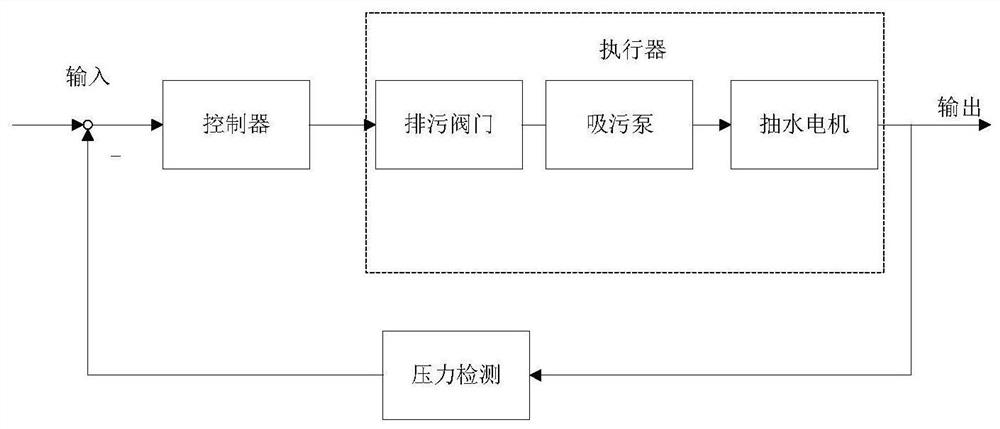

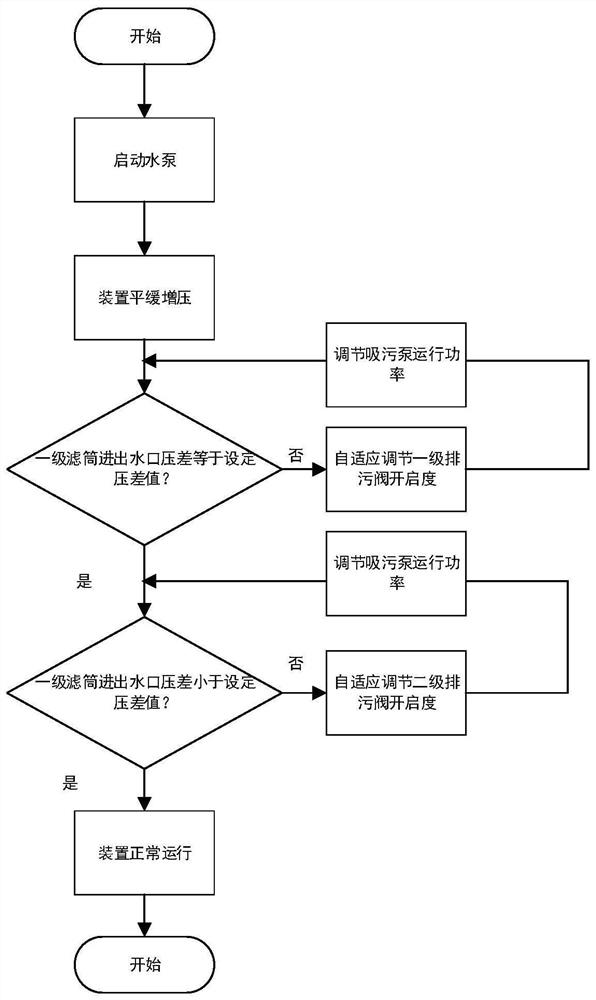

[0035] like figure 1 , 2 As shown in and 4, the present invention provides a centrifugal vortex ballast water filtration method with an adaptive cleaning function, and the ballast water filtration device for realizing the method includes:

[0036] Filter cartridge assembly: It is composed of cascaded two-stage conical vertical filter cartridges, and the inner surface of each conical vertical filter cartridge is provided with internal spiral threads to separate dirt through water vortex;

[0037] Suction pump: set at the front end of the inlet of the first-stage conical vertical filter cartridge 1 to pump the seawater to be treated into the first-stage conical vertical filter cartridge 1;

[0038] Screen filter cartridge 7: set at the water outlet of the second-stage conical vertical filter cartridge 2 to achieve final filtration;

[0039] Sewage collecting assembly: including a sewage pipeline connected to the sewage outlet of the two-stage conical vertical filter cartridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com