Automatic caulking device

An automatic, caulking technology, applied in the engineering field, can solve the problems of trivial steps, high expenditure, low technical content, etc., and achieve the effects of slowing down the setting time, solving poor fluidity and prolonging usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

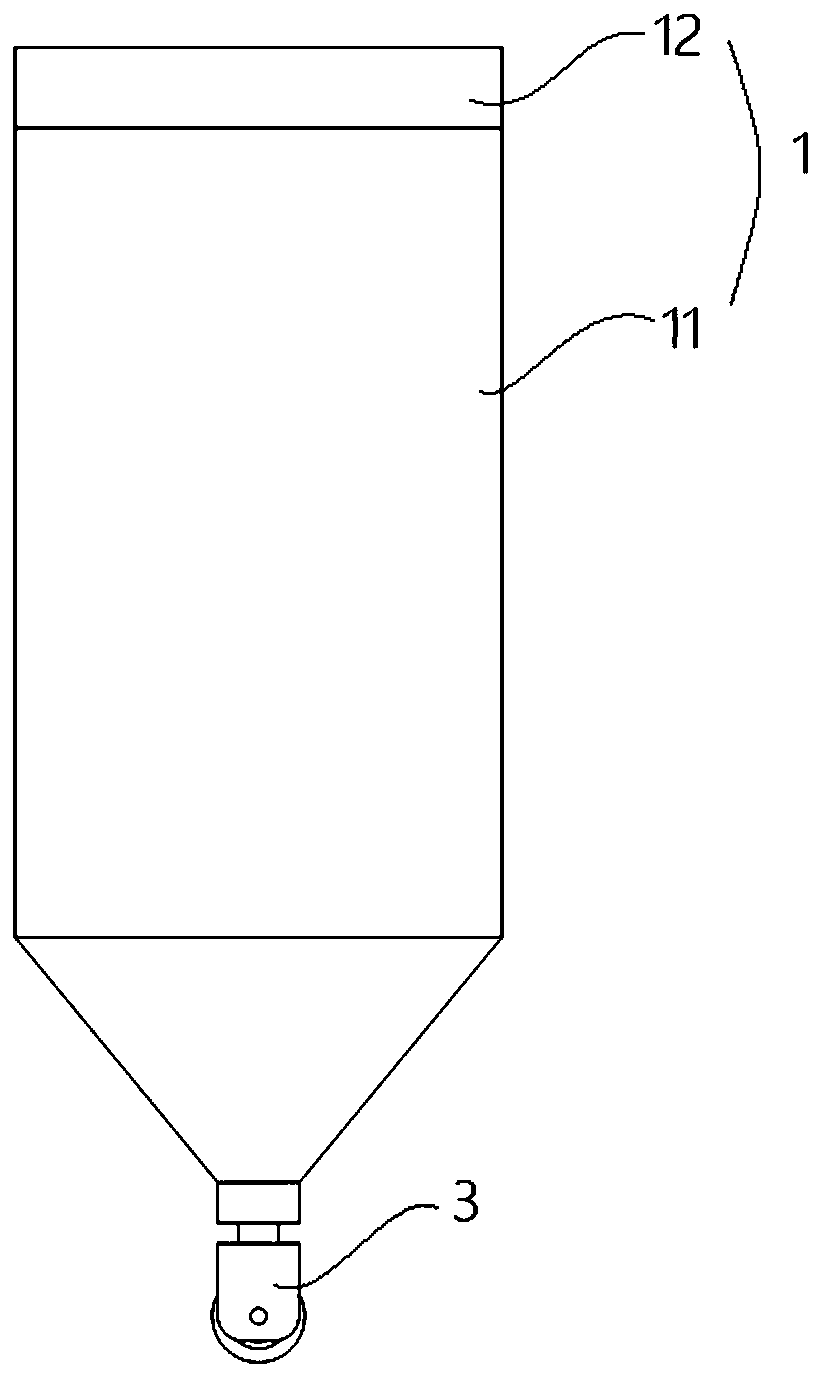

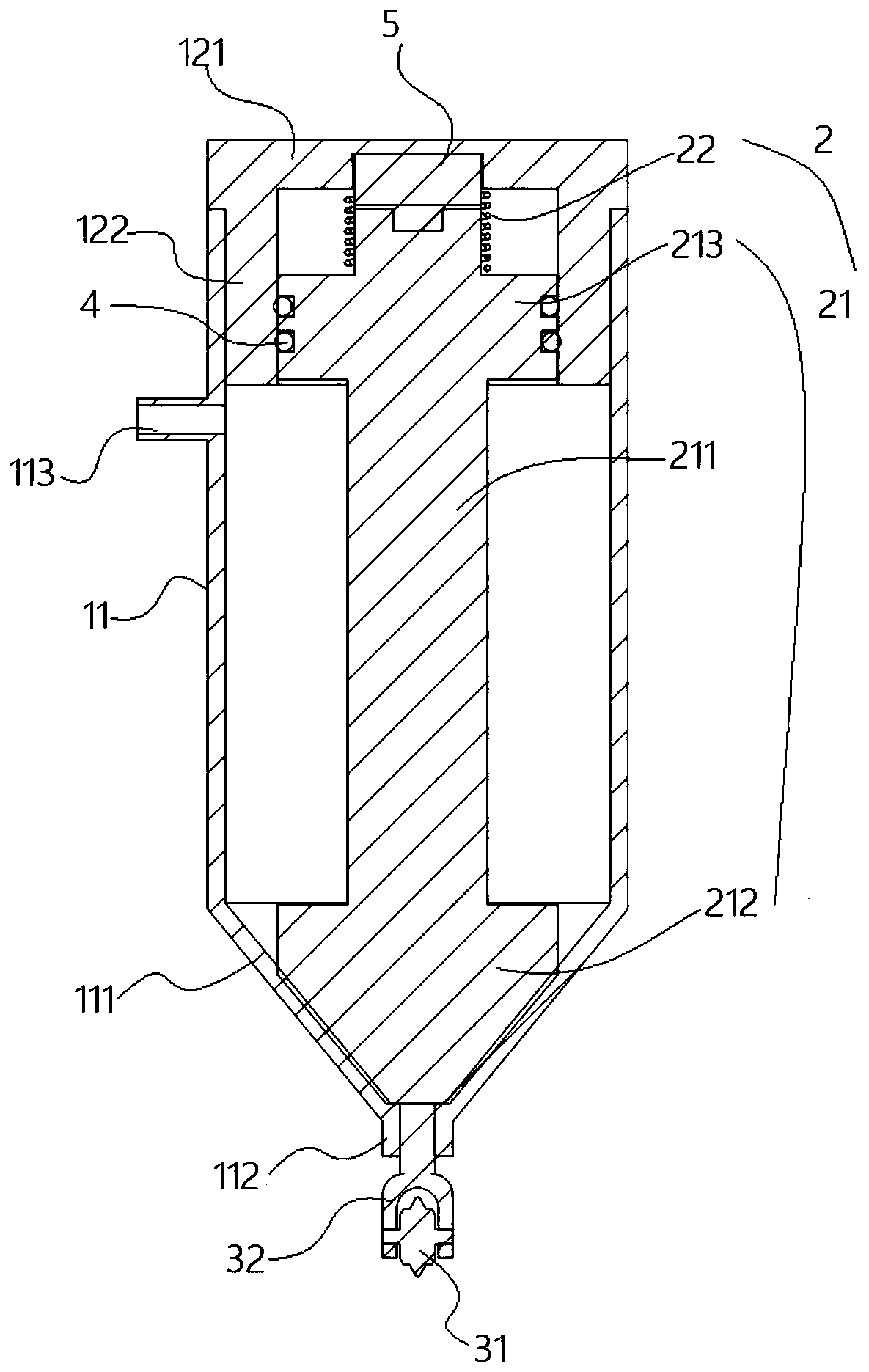

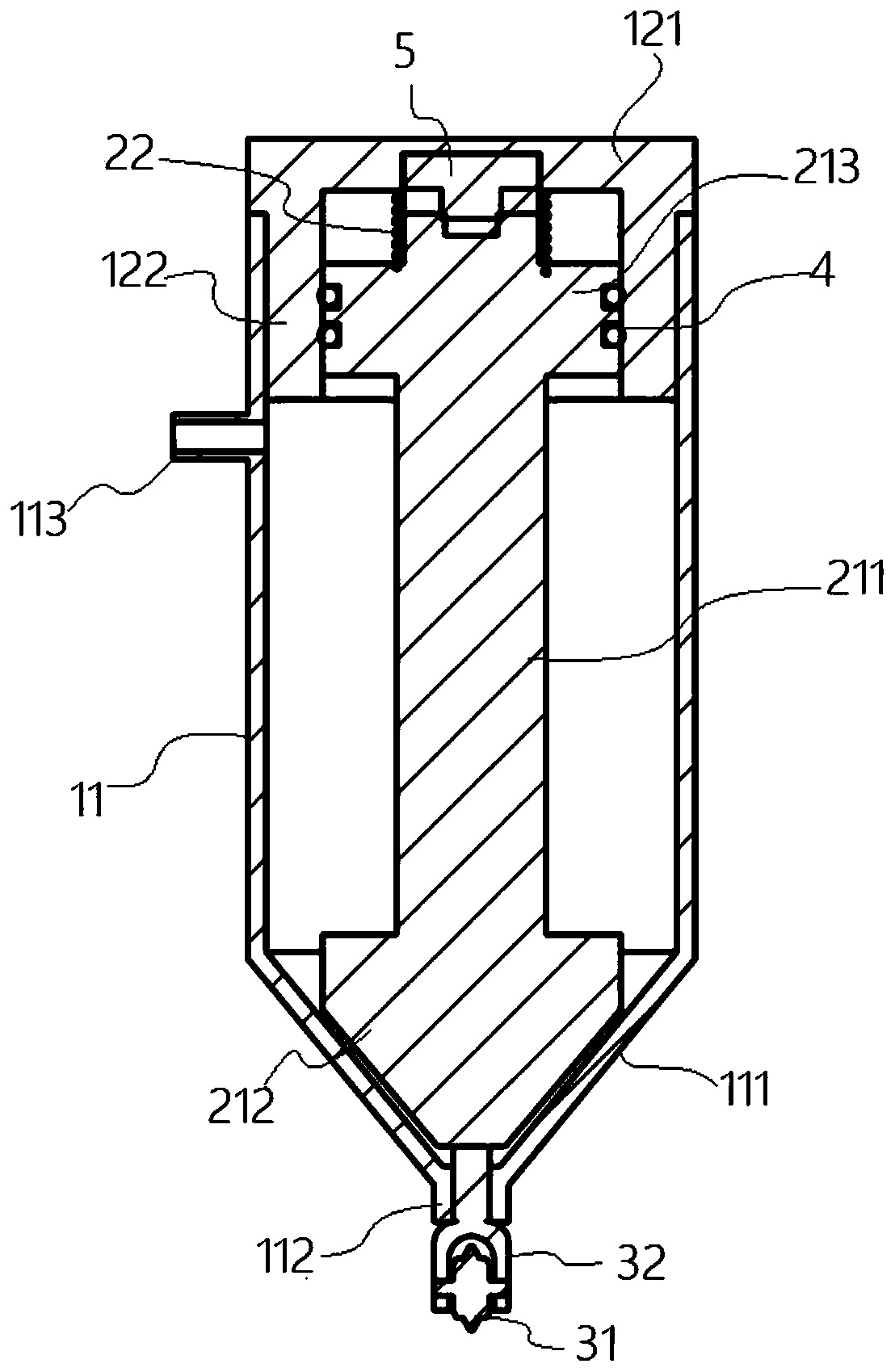

[0044] Such as Figure 2-3As shown, the material storage cylinder 1 includes a cylinder body 11, the discharge port 112 is located at the lower end of the cylinder body 11, the upper end of the cylinder body 11 is open, the opening is provided with a cylinder cover 12, and the plunger mechanism 2 is telescopically arranged on the Inside the cylinder body 11 and stop against the cylinder cover 12 . The plunger mechanism 2 includes a plunger 21 and an elastic member 10. The plunger 21 includes a plunger rod 211, a first end 212 and a second end 213 positioned at both ends of the plunger rod 211; It is arranged in the length direction and maintains a certain gap with the cylinder wall of the cylinder 11; the first end 212 is located at the lower end of the cylinder 11 for opening and closing the discharge port 112, and the roller mechanism 3 is fixedly connected to the first end through the discharge port 112 212; the second end 213 is located at the upper end of the barrel 11, ...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that in this embodiment, the plunger mechanism is telescopically arranged outside the storage cylinder.

[0054] Specifically, the material storage cylinder includes a cylinder, the lower end of the cylinder is provided with a discharge port, the upper end is provided with an opening, the opening is provided with a cylinder cover, and the plunger mechanism is telescopically arranged outside the cylinder and connected to the cylinder. The cylinder cover stops.

[0055] The plunger mechanism includes a plunger and an elastic member, the plunger includes a plunger rod, and a first end portion and a second end portion located at both ends of the plunger rod, the first end portion is annular and located outside the storage cylinder, and It can move back and forth along the wall of the storage cylinder, the second end is rod-shaped and horizontally located below the discharge port, one end is connected with the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com