Sampling mechanism for high-temperature waste gas laboratory detection

A high-temperature waste gas, laboratory technology, used in sampling, sampling devices, measuring devices, etc., can solve the problems of clogging of sampling tools, air bag sampling, condensation of volatile pollutants, etc., to achieve the effect of simple structure and improved authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

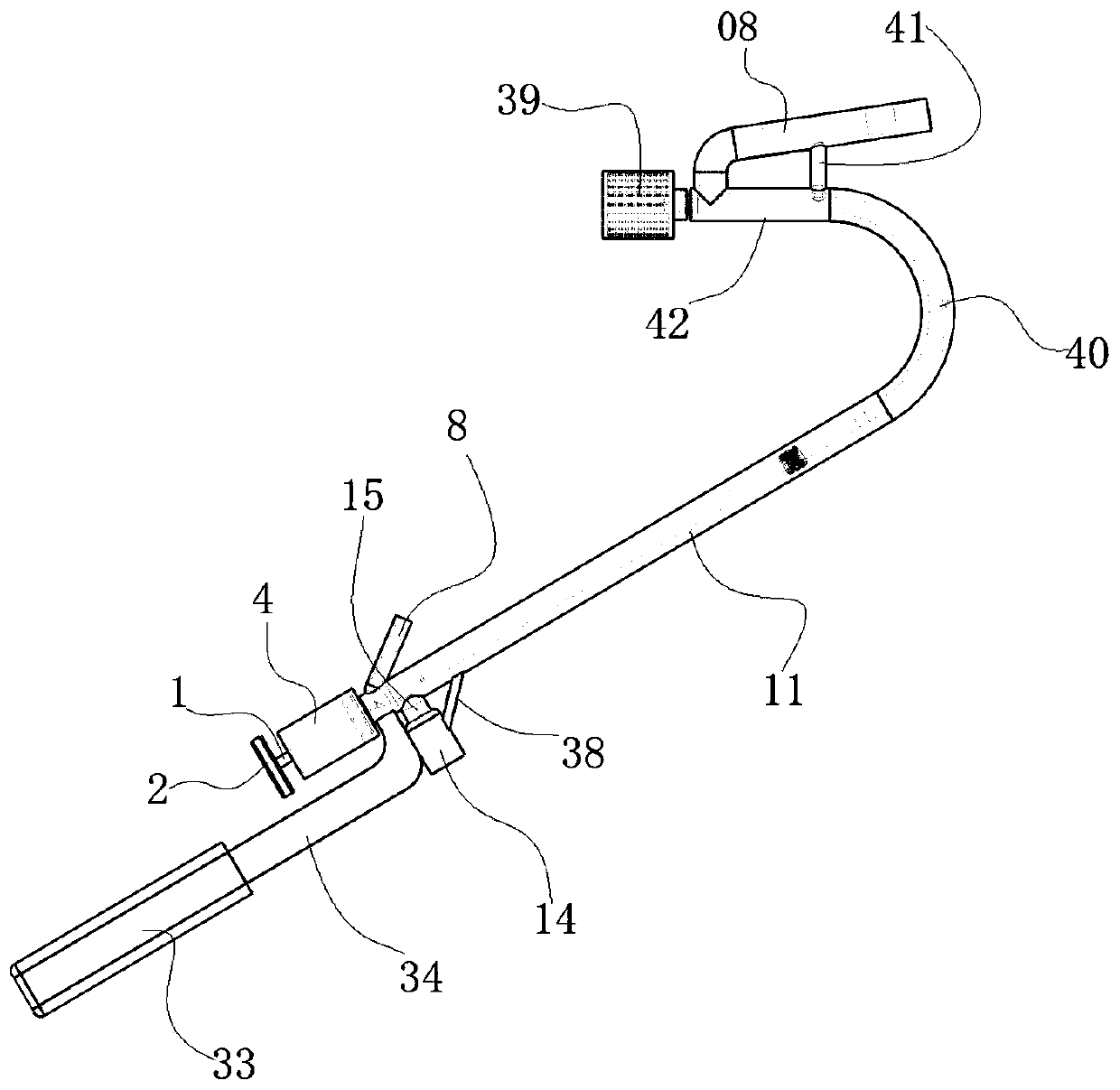

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

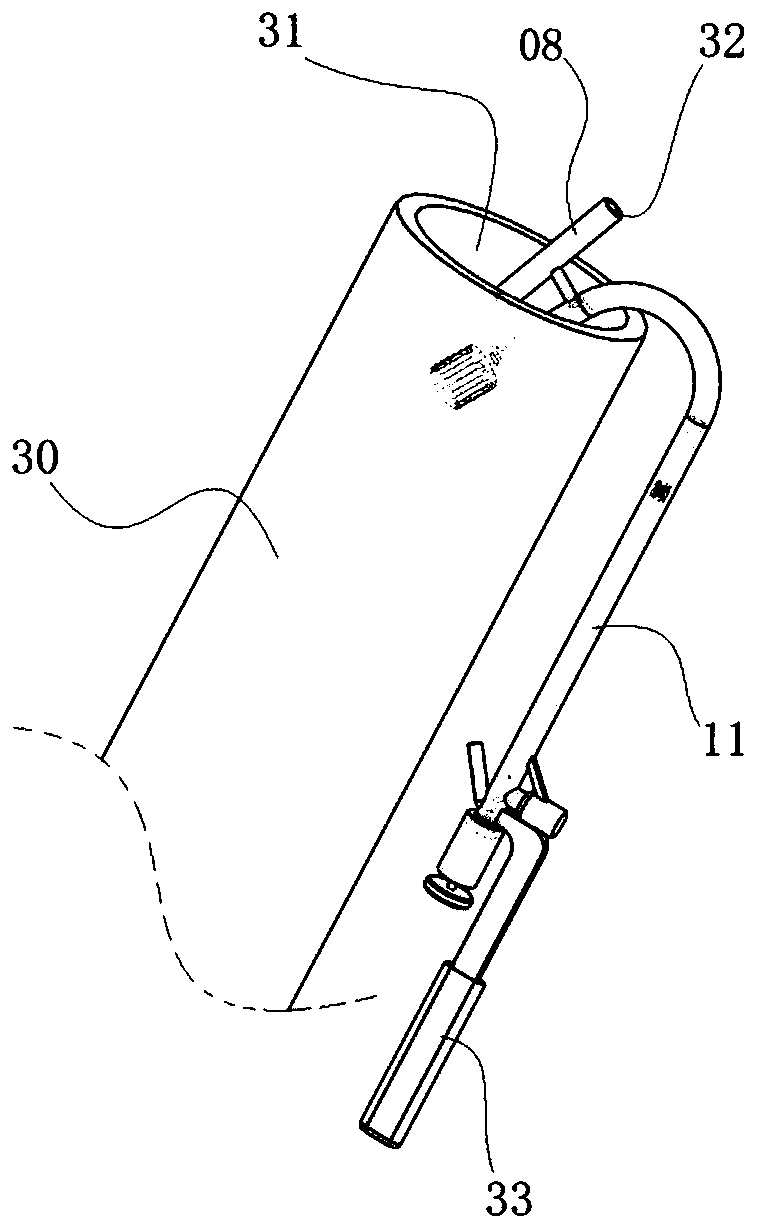

[0041] as attached Figures 1 to 14 The sampling mechanism shown in the high-temperature exhaust gas laboratory test includes a high-temperature exhaust pipe 30, and one end of the high-temperature exhaust pipe 30 is a high-temperature exhaust gas exhaust port 31;

[0042] It also includes a long rod-shaped sampling tool. One end of the sampling tool is set in a curved structure. Part of the smoke sample.

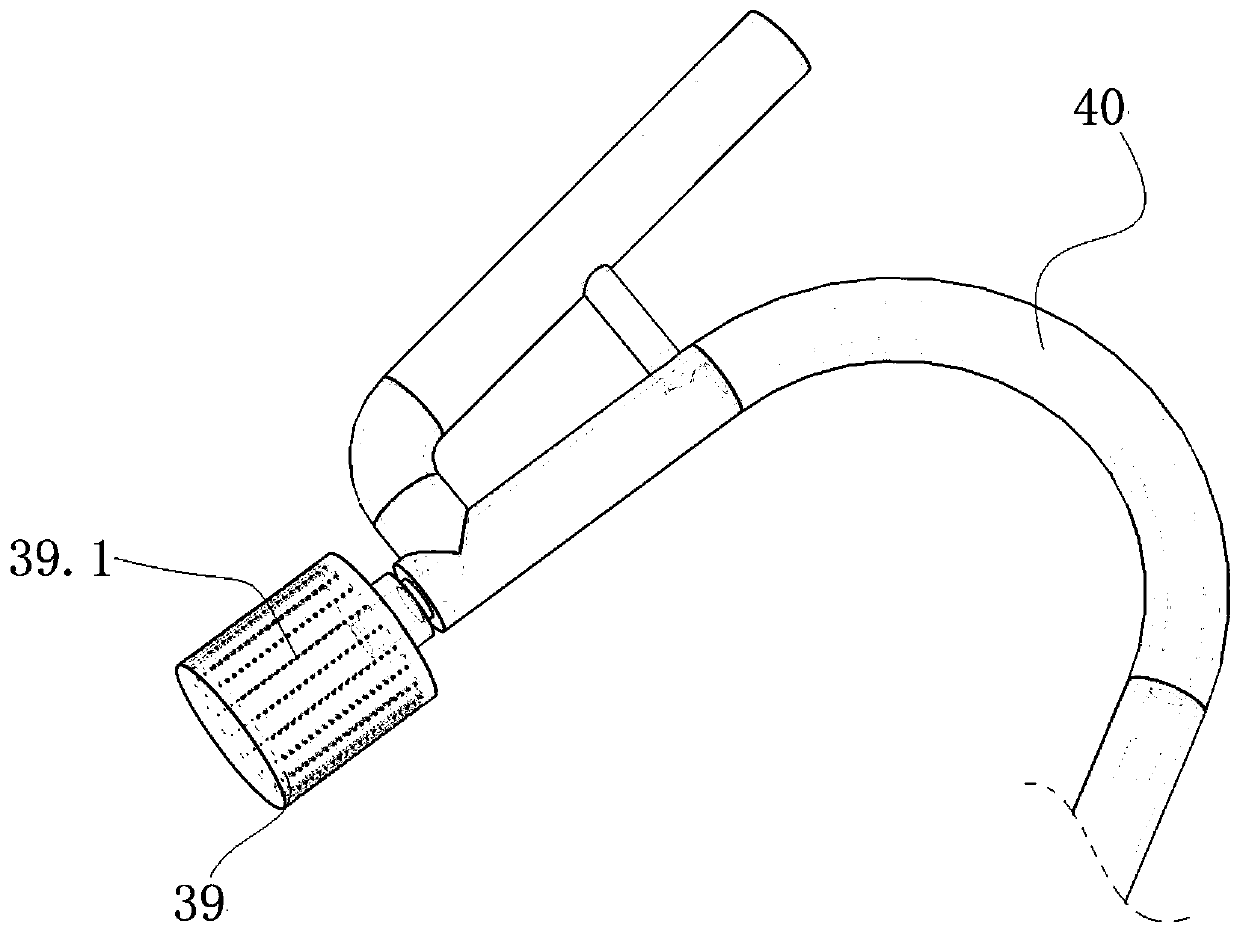

[0043]The sampling tool includes a hard outer tube body structure, and the outer tube body structure includes a first straight outer tube 11, an arc-shaped curved outer tube 40, and a second straight outer tube 42 that are sequentially integrated and communicated along the length direction. The end of the outer tube 11 is detachably connected to the sample storage tube 4, and the end of the second linear outer tube 42 is a sampling end, and the sampling end is als...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap