Reservoir micro-capillary porosity determination method based on constant-pressure mercury injection experiment

A technology of microcapillary and determination method, applied in the direction of suspension and porous material analysis, measurement device, instrument, etc., can solve the problem of separate determination of reservoir microcapillary porosity, lack of, limitation of quantitative understanding and application of reservoir microcapillary porosity and other problems to achieve the effect of expanding use, strong practicability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0028] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

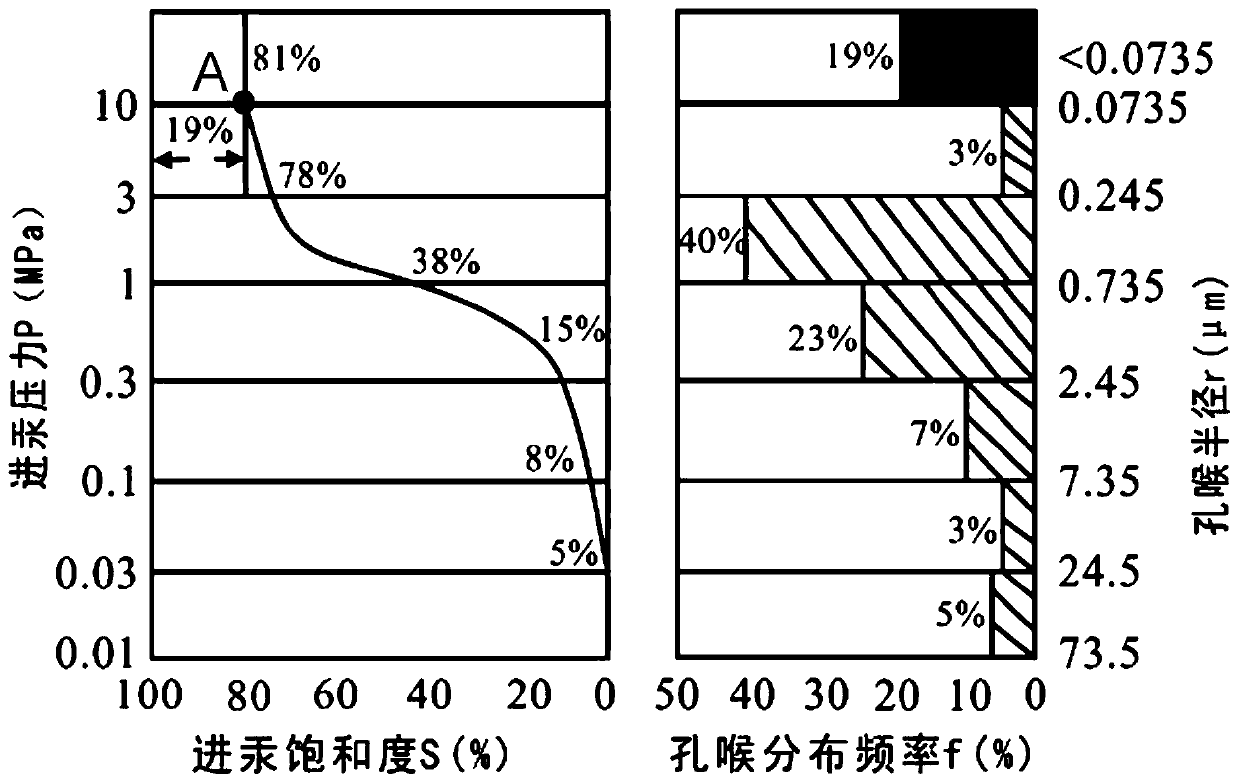

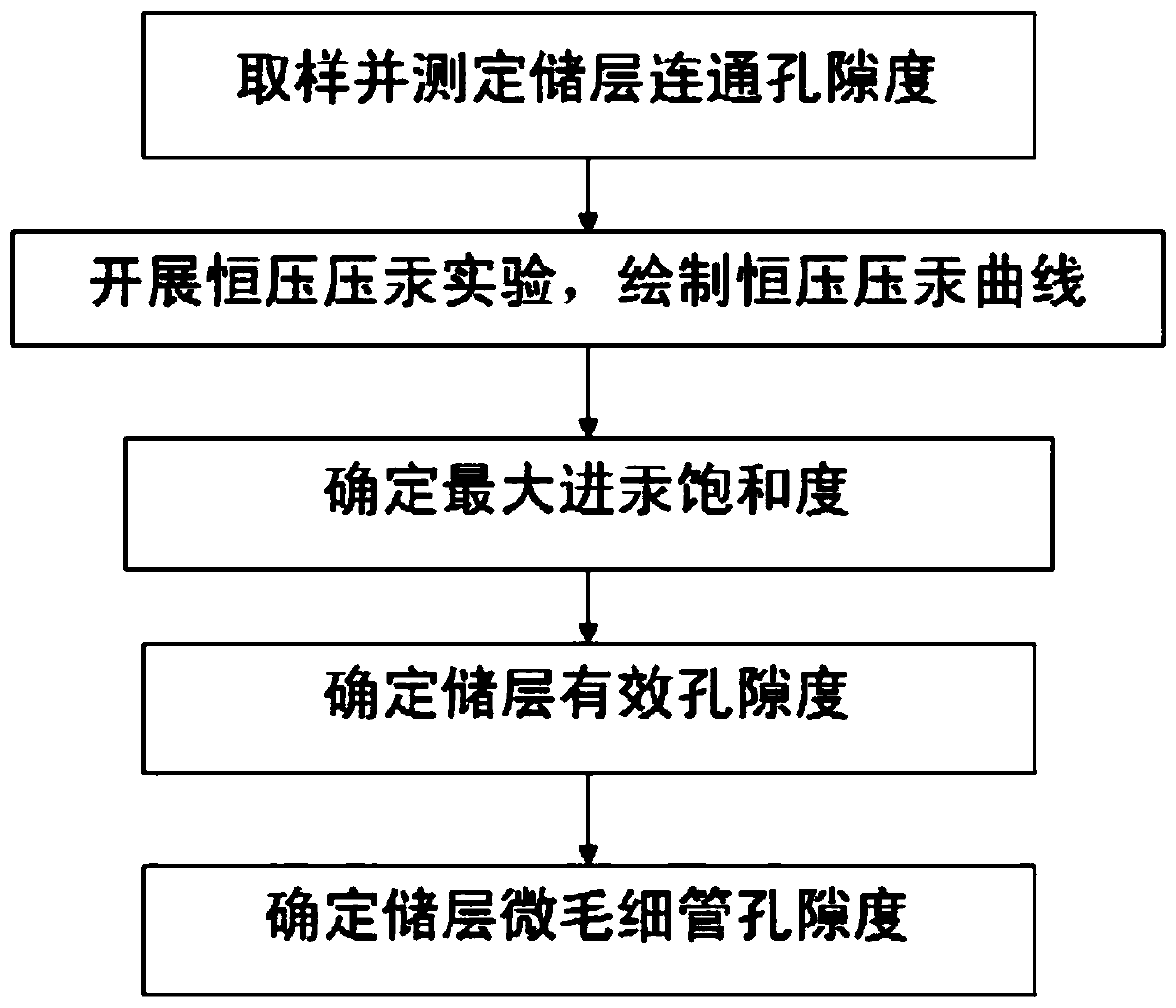

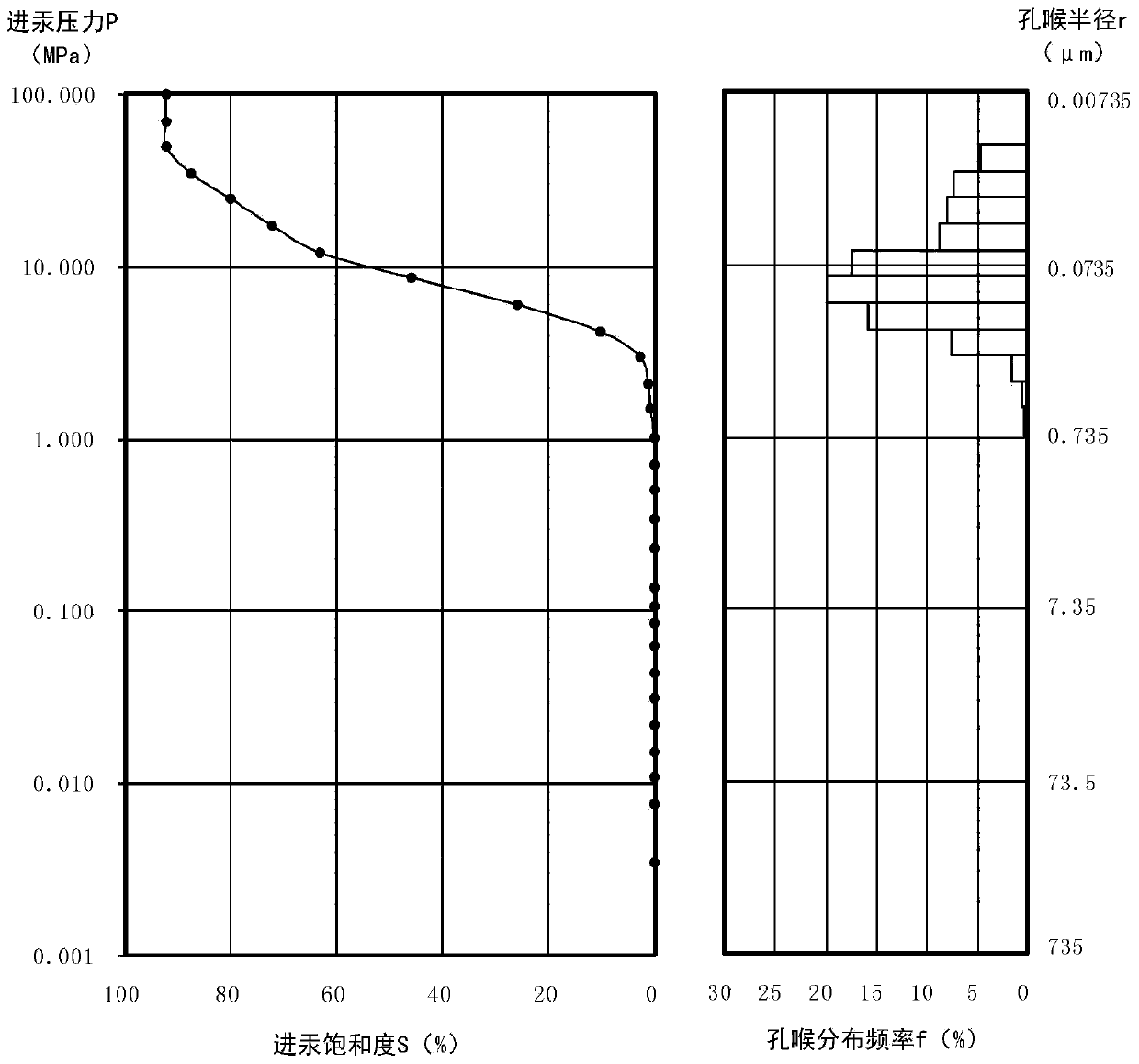

[0029] figure 2 It is the flow chart of the method for determining the microcapillary porosity of the reservoir based on the constant pressure mercury intrusion experiment of the present invention, such as figure 2 As shown, the reservoir microcapillary porosity determining method based on constant pressure mercury injection experiment of the present invention comprises the following steps:

[0030] 1) Sampling and measuring reservoir connected porosity

[0031] The oilfield reservoir is sampled, and the connected porosity of the reservoir is determined by the gas measurement method in the laboratory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com