State monitoring method for non-stationary industrial process based on slow feature analysis

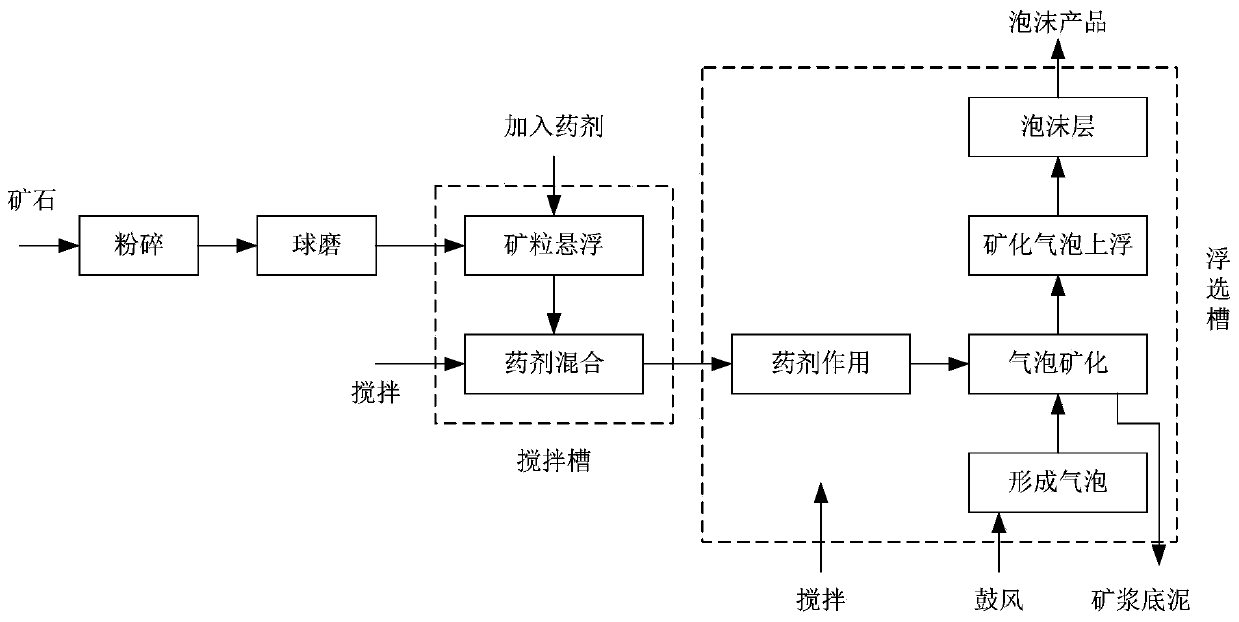

An industrial process, non-stationary technology, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

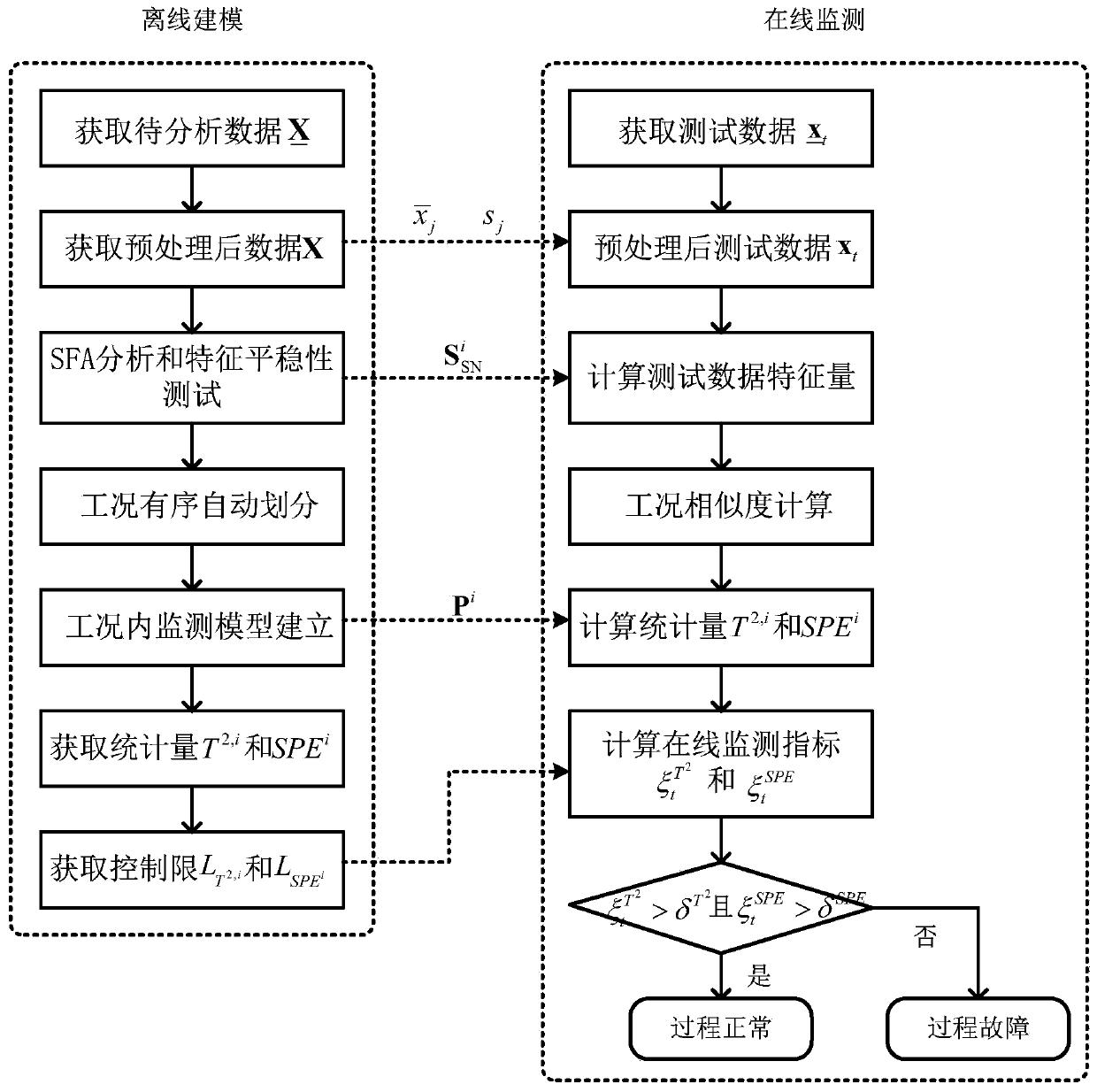

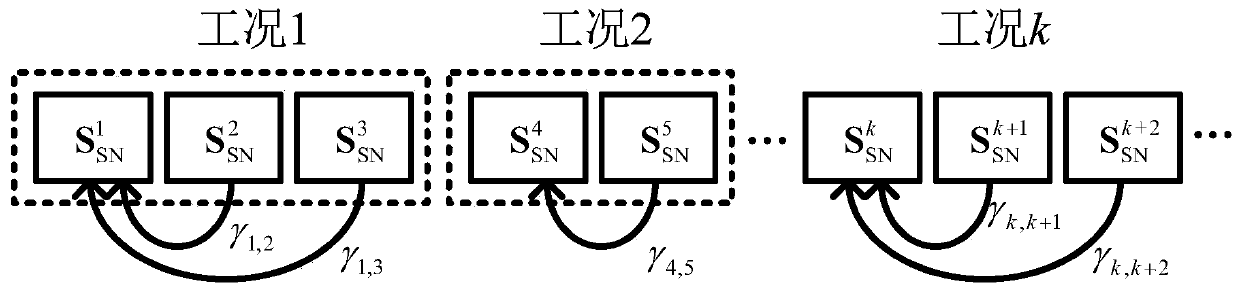

Method used

Image

Examples

Embodiment 1

[0125] Figure 5 The data of normal operation under working condition 2 shown: the results of intermediate statistics under working condition 2 are as follows Figure 6 As shown, the solid line is the intermediate statistics, and the dotted line is the control limit. It can be seen that the sample points are basically below the control limit. The results of intermediate statistics under working condition 3 are as follows Figure 7 As shown in , the SPE statistic is intermittently exceeding the limit, because the current test condition does not match the condition 3, so the model does not match. Further, according to step (8.3), obtain the process status monitoring index, such as Figure 8 As shown, the solid line is the indicator trend, and the dotted line is the threshold. It can be seen that based on T 2 The state monitoring indicators of SPE and SPE statistics are both greater than the threshold, that is, the process is considered to be in normal operating state. The ...

Embodiment 2

[0127] The process working condition is converted from 2 to 3, wherein, the 20th to 120th sampling points are abnormal: the trend of the monitoring index obtained by the method proposed by the present invention is as follows Figure 10 As shown in , the dotted box indicates the 20th to 200th sampling points, it can be seen that the SPE-based monitoring indicators prepared to find process abnormalities. Using PCA method for state monitoring, the results are as follows Figure 11 shown. can be found, T 2 Both the and SPE statistics are below the control limits, and PCA cannot detect process anomalies. The comparison results of Example 2 prove the effectiveness and sensitivity of the proposed method.

[0128] Generally speaking, the state monitoring method based on the present invention can effectively divide the working conditions of the process, and distinguish the normal state and the abnormal state of the process. This is difficult to achieve with traditional non-stationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com