A step-by-step leaching method for remediation of heavy metal chromium contaminated soil

A technology for chromium-contaminated soil and heavy metals, applied in the field of soil remediation, can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

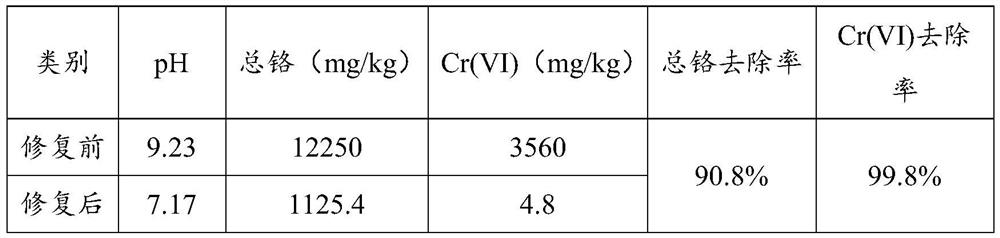

Embodiment 1

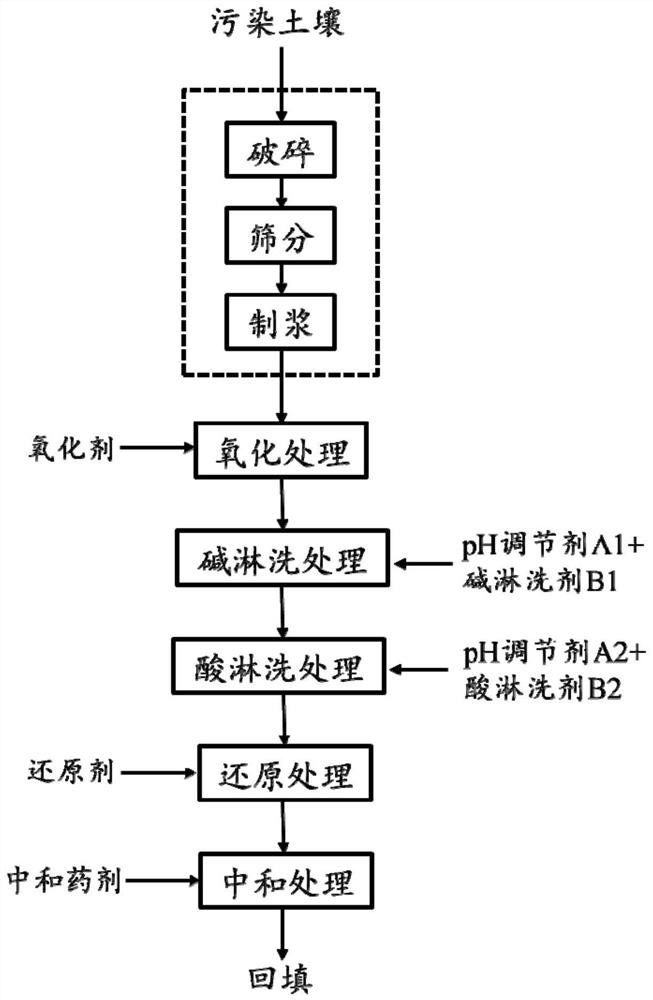

[0037] A step-by-step leaching method for remediation of heavy metal chromium-contaminated soil, according to figure 1 The process flow chart shown includes processes such as pretreatment, oxidation, alkali rinsing, acid rinsing, reduction and neutralization, and specifically includes the following steps:

[0038] (1) Air-dry and crush the contaminated soil, pass it through a 10-mesh sieve, take 100 g of the sieved soil, put it in a 2L beaker, add deionized water at a solid-to-liquid ratio of 1:20, and mix and stir for 5 minutes;

[0039](2) in the slurry prepared in (1), fill ozone and carry out oxidation, oxidation time 15min; Ozone adopts ozone generator to make, and ozone concentration is 20mg / L, and ozone generation is 20g / L;

[0040] (3) Add pH adjuster A1 sodium hydroxide solution to the slurry after (2) oxidation treatment, adjust the pH value to >10, and the concentration of sodium hydroxide solution is 4mol / L; stir and mix for 15min, then add alkali rinse agent B1"K...

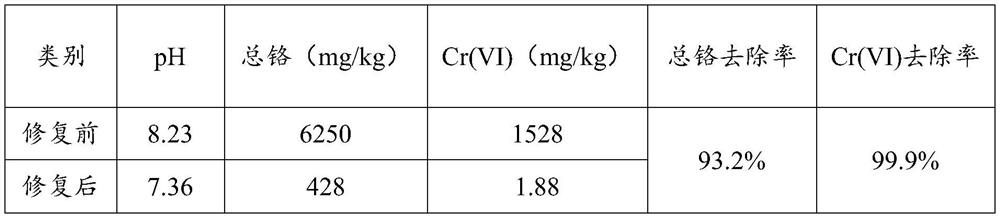

Embodiment 2

[0048] A step-by-step leaching method for remediation of heavy metal chromium-contaminated soil, specifically comprising the following steps:

[0049] (1) Air-dry and crush the contaminated soil, pass through a 10-mesh sieve, take 300 g of the sieved soil and place it in a 5L beaker, add deionized water at a solid-to-liquid ratio of 1:10, and mix and stir for 5 minutes;

[0050] (2) Fill the slurry prepared in (1) with ozone for oxidation, and the oxidation time is 10 minutes. Ozone uses an ozone generator with an ozone concentration of 15mg / L and an ozone production of 20g / L;

[0051] (3) Add pH adjuster A1 sodium hydroxide solution to the slurry after the oxidation treatment in (2) to adjust the pH value to >10, and the concentration of the sodium hydroxide solution is 4mol / L. Stir and mix for 15 minutes, then add the combined solution of alkali rinse agent B1 "polyphosphate + sodium lignosulfonate", wherein the dosage of polyphosphate is 0.5%, and the dosage of sodium lign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com